Hydraulic high-frequency down-the-hole rock-breaking drill at the bottom of the rotary pile machine

A technology of rotary pile driver and hole bottom, which is applied to drill pipes, drill pipes, drilling equipment, etc., can solve the problems of only about 1 meter in 8 hours, the difficulty of drilling the drill bit into the rock quickly, and the inability to form holes at one time, so as to improve the penetration rate. The effect of rock efficiency, fast collection of crushed stone particles and high impact force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

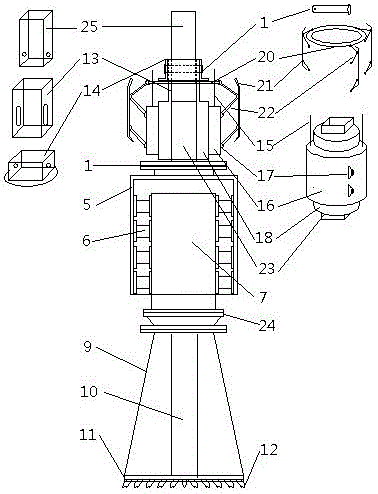

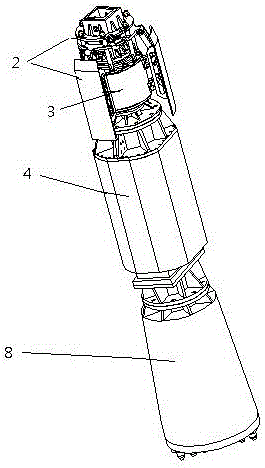

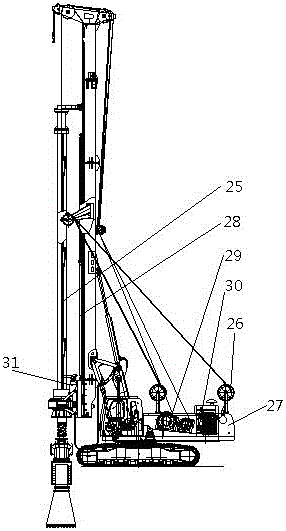

[0015] Such as figure 1 , 2 As shown, the upper end of the hydraulic down-the-hole rock-breaking drill of the present invention is provided with a detent mechanism 2 for controlling the rotary joint assembly 3, and the detent mechanism 2 is arranged on the outside of the rotary joint assembly 3. During operation, the rotary joint assembly 3 of the present invention passes through the The anti-rotation mechanism 2 is connected to the telescopic drill pipe 25 of the rotary pile excavator, and the telescopic drill pipe 25 is connected to the connection square sleeve 13 of the anti-rotation mechanism 2 through the pivot pin 19; the connection square sleeve 13 of the anti-rotation mechanism 2 is welded on the rotary joint The upper end of the central shaft 23 of the assembly 3; the rotary joint assembly 3 is composed of the rotary joint casing 16, the central shaft 23 arranged in the rotary joint casing 16, and the rotary joint mandrel 18, and the rotary joint mandrel 18 is arrange...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com