Tent frame rod structure capable of automatically unfolding and folding

A tent frame and pole structure technology, applied in the field of tents, can solve the problems of cumbersome unfolding and folding processes, time-consuming and labor-intensive, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

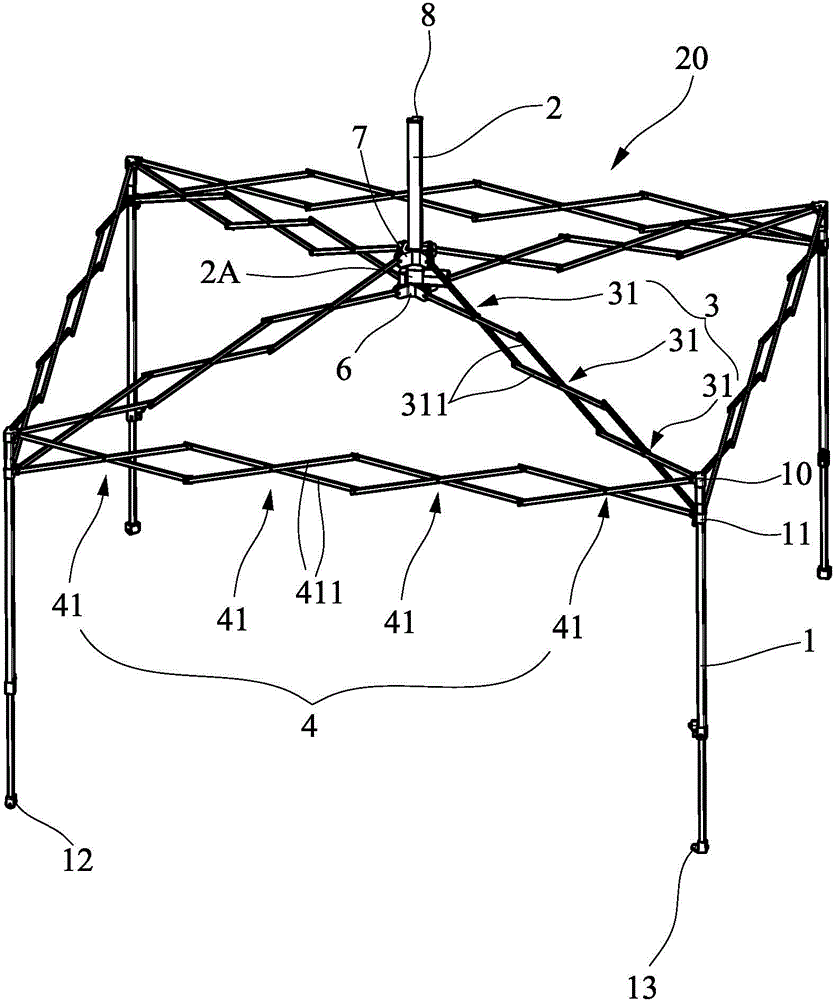

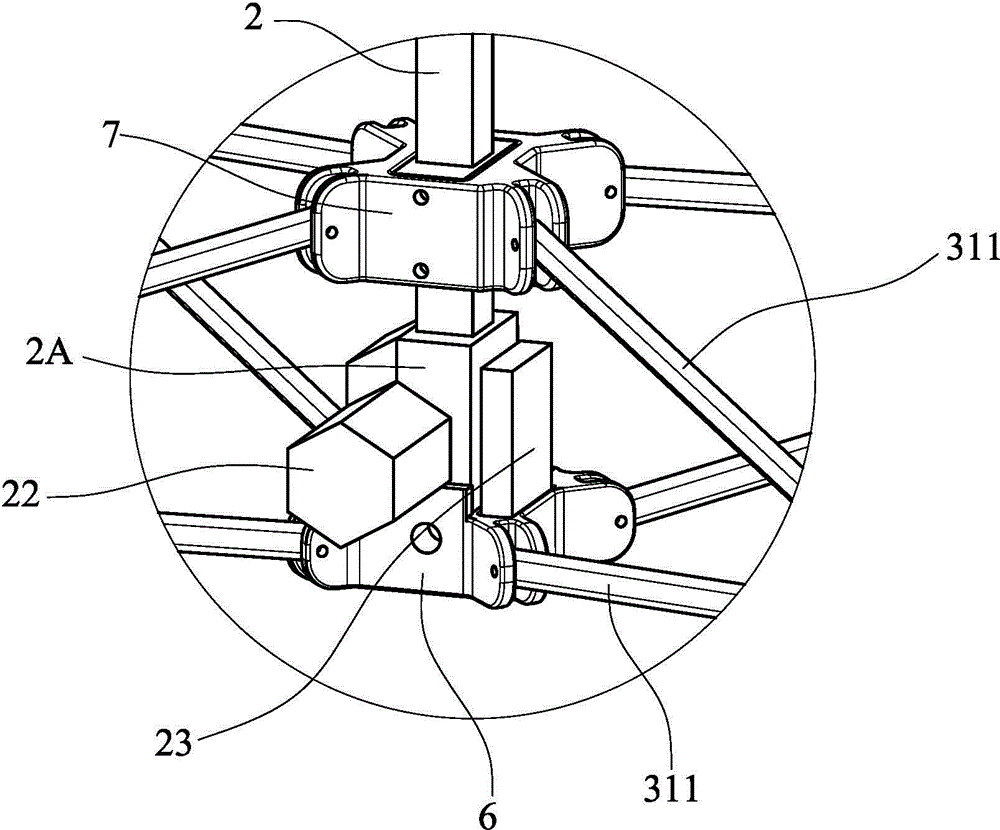

[0040] Such as figure 1 As shown, the tent pole structure of a kind of automatic retractable provided in this embodiment comprises: four upright poles 1 and a top support frame 20, and the top top support frame comprises an automatic retractable device, multiple groups of push rod groups 3 and Multiple groups of side rod groups 4, and the automatic retracting device includes guide rods 2 and driving devices 2A. The tops of the poles 1 and the guide poles 2 are in direct contact with the tent fabric and form support for the tent fabric. Of course, the number of poles 1 can also be three, five or more, which can be selected according to actual needs. A push rod group 3 is connected between the guide rod 2 and each vertical rod 1 , and a side rod group 4 is connected between every two adjacent vertical rods 1 .

[0041] The top of each pole is equipped with a fixed seat 10, and the shaft of the pole 1 is equipped with a sliding seat 11 that can slide along the pole 1. A fixed fo...

Embodiment 2

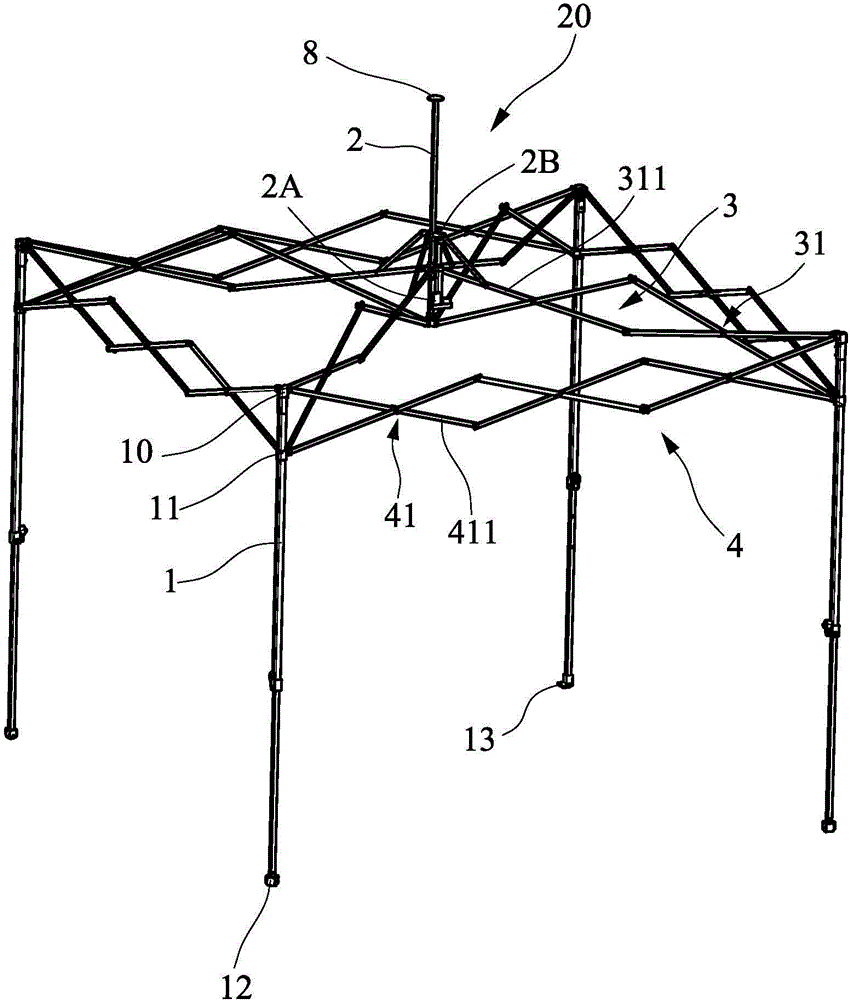

[0048] Such as Image 6 As shown, an automatically retractable tent pole structure provided in this embodiment includes: four vertical poles 1 and a top support frame 20, and the top top support frame 20 includes an automatic retractable device, multiple sets of push rod groups 3 And multiple groups of side rod groups 4, the automatic opening and closing device includes a guide rod 2 and a driving device 2A. The tops of the poles 1 and the guide poles 2 are in direct contact with the tent fabric and form support for the tent fabric. Of course, the number of poles 1 can also be three, five or more, which can be selected according to actual needs. A push rod group 3 is connected between the guide rod 2 and each vertical rod 1, and a side rod group 4 is connected between every two adjacent vertical rods 1. Each vertical rod 1 and each vertical rod 1 connected with the vertical rod 1 An oblique strut 5 is also connected to the group side rod group 4 .

[0049] The top of each po...

Embodiment 3

[0056] Such as Figure 7 As shown, an automatically retractable tent pole structure provided in this embodiment includes: four vertical poles 1 and a top support frame 20, and the top top support frame 20 includes an automatic retractable device, multiple sets of push rod groups 3 And multiple groups of side rod groups 4, the automatic opening and closing device includes a guide rod 2 and a driving device 2A. The tops of the poles 1 and the guide poles 2 are in direct contact with the tent fabric and form support for the tent fabric. Of course, the number of poles 1 can also be three, five or more, which can be selected according to actual needs. A push rod group 3 is connected between the guide rod 2 and each vertical rod 1 , and a side rod group 4 is connected between every two adjacent vertical rods 1 .

[0057] The top of each pole is equipped with a fixed seat 10, and the shaft of the pole 1 is equipped with a sliding seat 11 that can slide along the pole 1. A fixed foot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com