Shaft type lifting system for protecting steel wire rope

A steel wire rope and shaft type technology, applied in the field of hoisting equipment, can solve problems such as easy damage of wire ropes, and achieve the effects of prolonging service life, reducing damage and reducing friction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

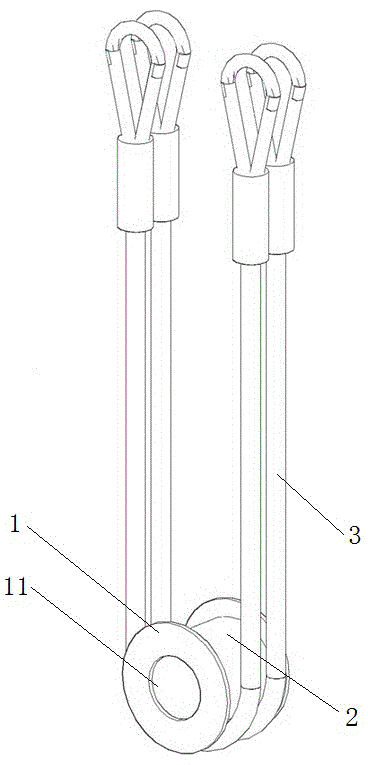

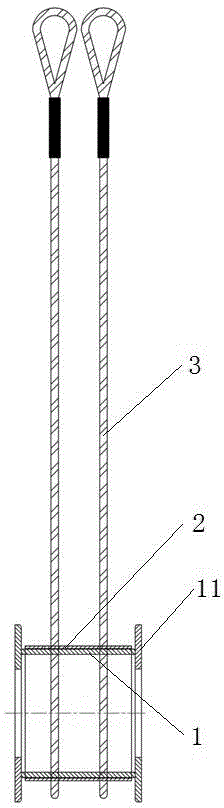

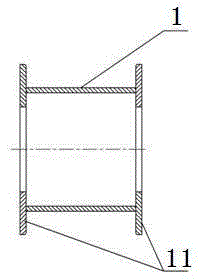

[0015] The structure of a specific embodiment of the present invention is as Figure 1 to Figure 4 As shown, this is the shaft-type hoisting system for protecting wire ropes of the embodiment, including shaft-type lifting points 1 and steel wire ropes 3, and shaft-type lifting points 1 are provided with outer-profile protective sleeves that slide and fit with shaft-type lifting points 1 2. The outer profile protective cover 2 is set outside the shaft type lifting point 1, the steel wire rope 3 is hoisted outside the outer profile type protective cover 2, and the two ends of the shaft type lifting point 1 are fixed with respectively The baffle plate 21 that cooperates with the outer profile protective cover 2 is blocked, and the baffle plate 21 is detachably and fixedly installed on the two ends of the shaft type suspension point 1. An oil in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com