a carrier mechanism

A carrier and Y-axis technology, applied in the direction of layered products, lamination auxiliary operations, lamination, etc., can solve problems such as inaccuracy and deviation, achieve accurate positioning, and ensure the effect of lamination accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

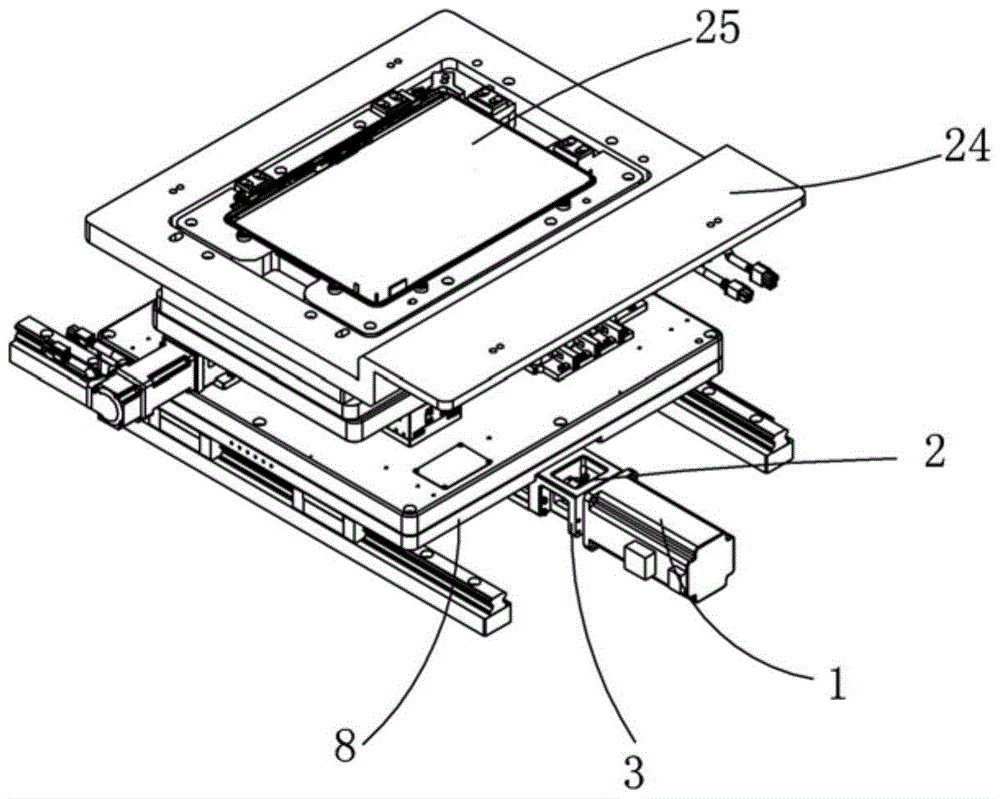

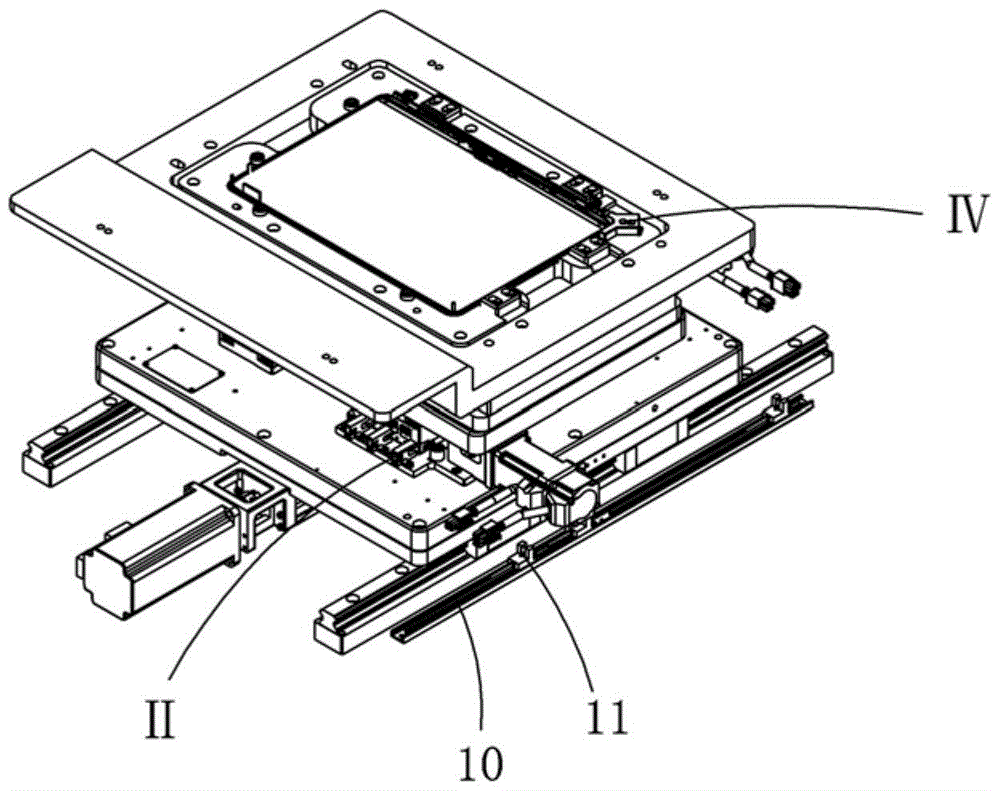

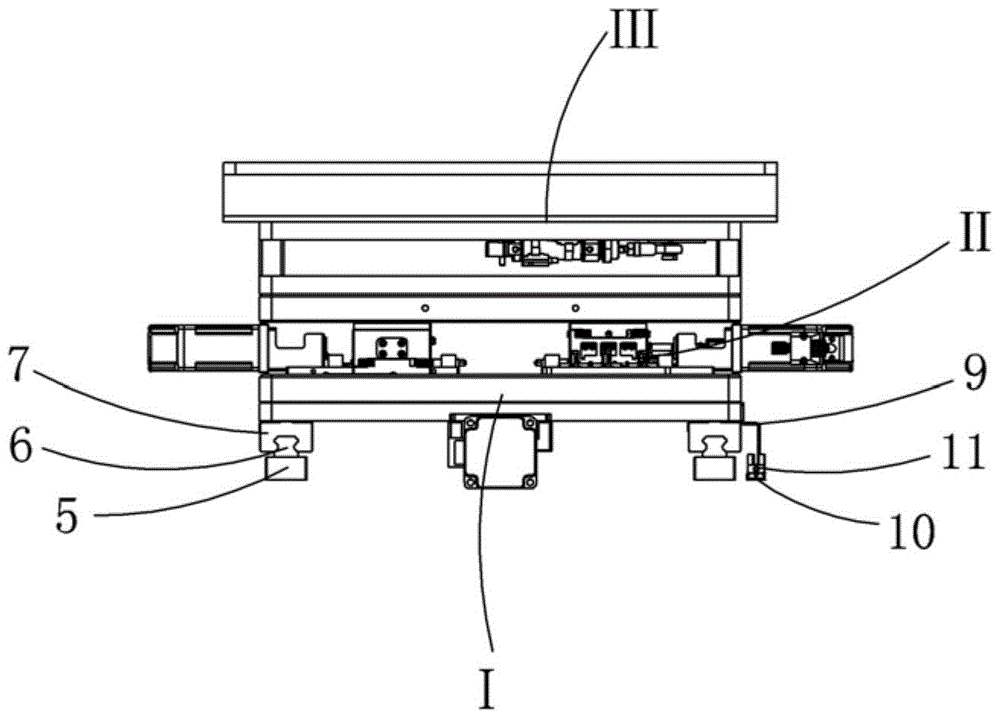

[0028] Examples, see attached Figure 1-8 , a carrier mechanism, which includes a Y-axis mechanism I, and the Y-axis mechanism includes a Y-axis motor 1, a Y-axis coupling 2, a Y-axis linear module 3, a Y-axis linear module slider 4, and a pad 5. The Y-axis slide rail 6 and the Y-axis slider 7. There are two sets of pads, which are symmetrically arranged on the left and right sides of the Y-axis linear module, and the pads and the Y-axis linear module are parallel to each other; A Y-axis slide rail is installed on the pad, and a Y-axis slider is installed on the Y-axis slide rail; the Y-axis motor is connected with the Y-axis linear module through a Y-axis coupling, and the Y-axis linear module is It is equipped with a Y-axis linear module slider. The Y-axis linear module slider and the Y-axis slider of the Y-axis mechanism are equipped with a moving plate 8, the right side of the moving plate is equipped with a Y-axis induction plate 9, and the right side of the spacer is pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com