Quilt washing line

An assembly line and bedding technology, applied to washing devices, laundry room devices, other washing machines, etc., can solve the problems of shortening the service life of bedding, fiber agglomeration, and reducing the heat preservation performance of bedding, and achieve low washing cost and low washing energy consumption , High washing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be described in further detail below in conjunction with the accompanying drawings and preferred embodiments.

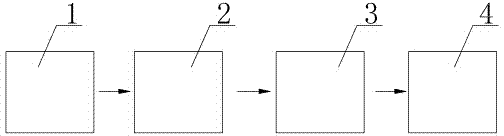

[0036] Such as figure 1 As shown, the quilt washing line includes a rolling device 1 for rolling the quilt into a roll, an elution device 2 for washing and dehydrating the roll-shaped quilt, and a washing device 2 for washing the quilt A drying device 3 for drying the bedding, and a restoring device 4 for restoring fluffy bedding after drying.

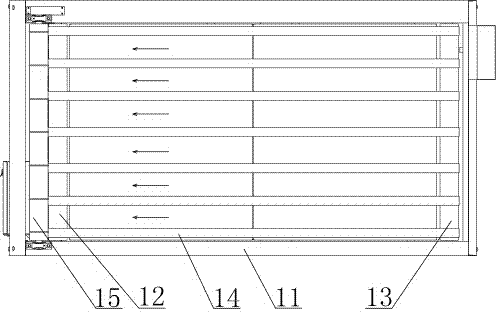

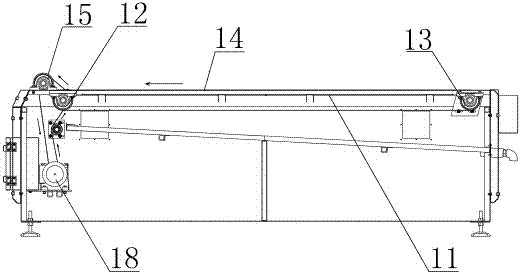

[0037] Such as figure 2 , image 3 As shown, the structure of the rolling device 1 described in this embodiment includes: a rolling table 11 and a rolling driving device 18, and a driving roller 12 and a driven roller are respectively arranged at both ends of the rolling table 11 Roller 13, driving roller 12 and driven roller 13 are provided with several conveyor belts 14, and rolling roller 15 is also installed on the rolling workbench 11 outside driving roller 12, and rolling roller 15 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com