Ceramic filter tube air permeability automatic detection line

A ceramic filter tube, automatic detection technology, applied in the direction of conveyor objects, conveyors, mechanical conveyors, etc., can solve the problems of inaccurate product quality control, inconsistent product quality, difficult to control error rate, etc., to improve product quality The effect of controlling the level, reducing labor and saving costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] The present invention will be further described below in conjunction with embodiment:

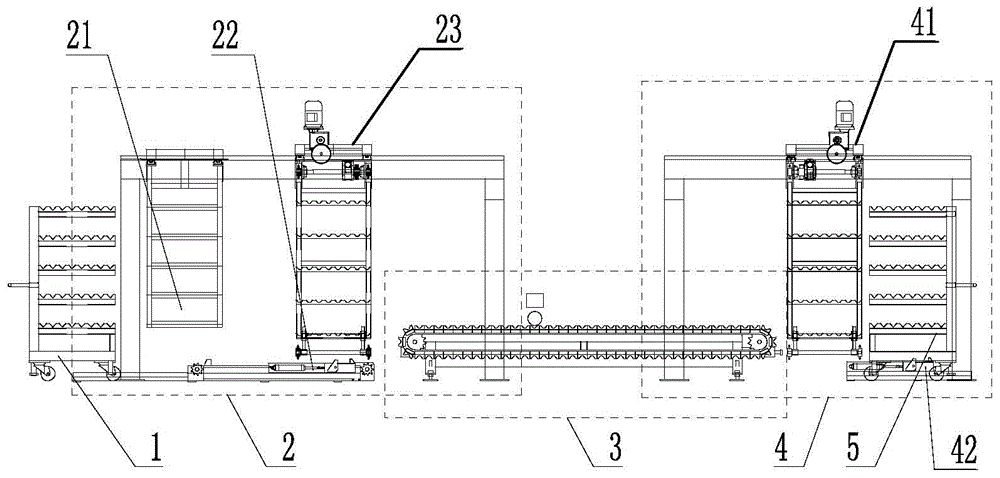

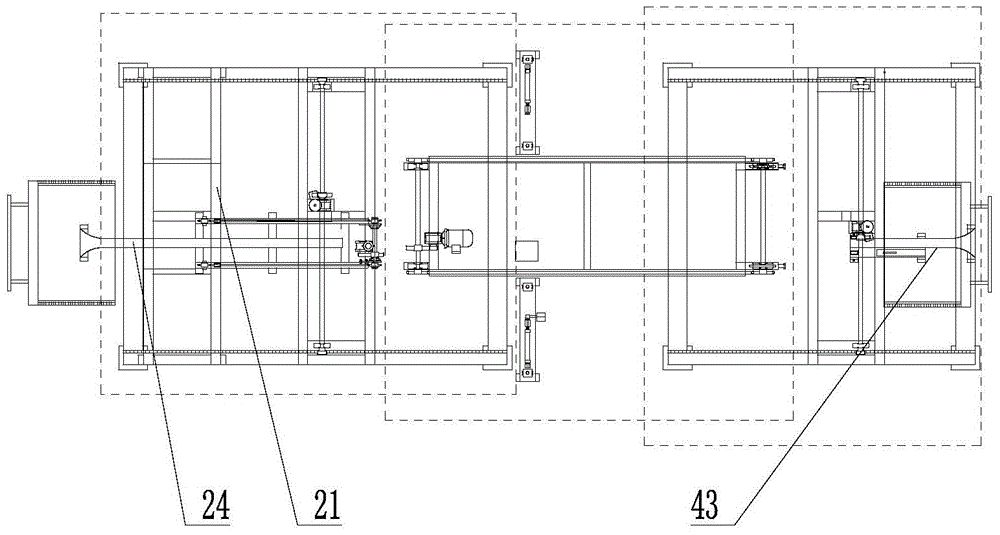

[0051] like Figure 1 ~ Figure 2 As shown, the ceramic filter tube air permeability automatic detection line of the present invention includes a detection device 3, the front end of the detection device 3 is sequentially provided with a feeding car 1 and a feeding device 2, and the rear end of the detection device 3 is sequentially provided with a discharge device 4 and Unloading truck 5.

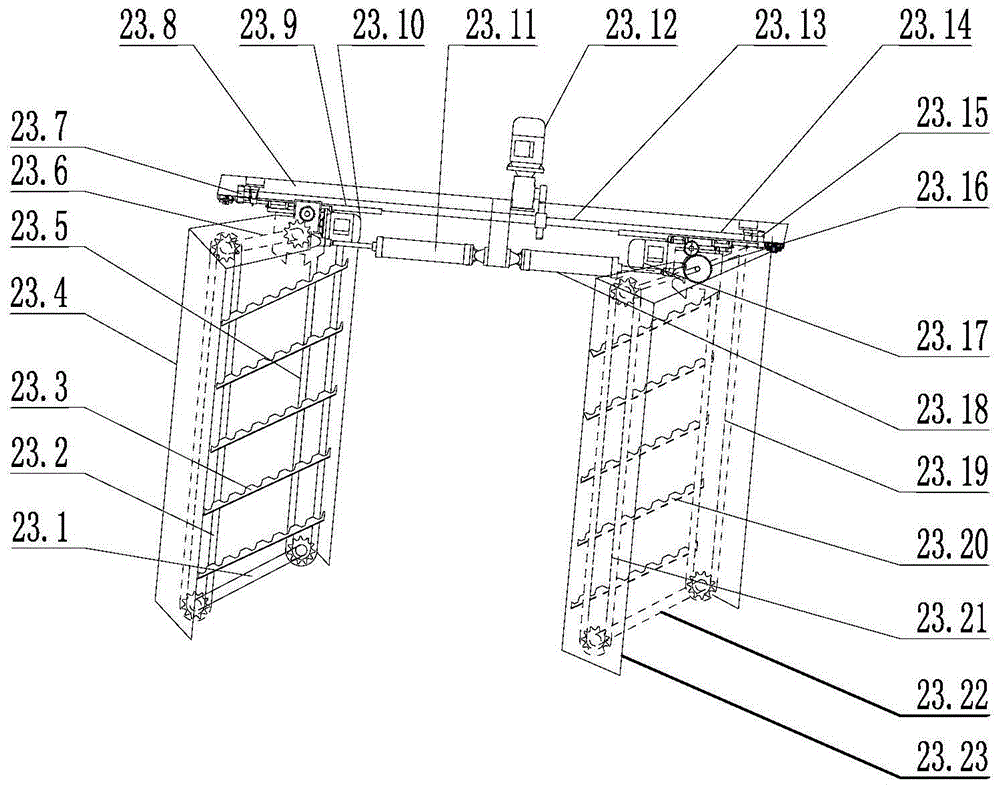

[0052] The feeding device 2 includes a traction device 24, a centering device 21, a positioning device 22 and a transport trolley 23. The centering device 21 and the transport trolley 23 are located at the top of the traction device 24 and the positioning device 22, and the centering device 21 is located at the front of the transport trolley 23. , the positioning device 22 is located at the rear end of the traction device 24 .

[0053] The unloading device 4 includes a transport trolley 41, a tr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com