A full paper tray

A pallet and corrugated cardboard technology, applied in the field of all-paper pallets, can solve the problems of complex processing procedures and heavy wooden pallets, and achieve the effects of reducing production costs, labor costs and maintenance costs, and saving costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

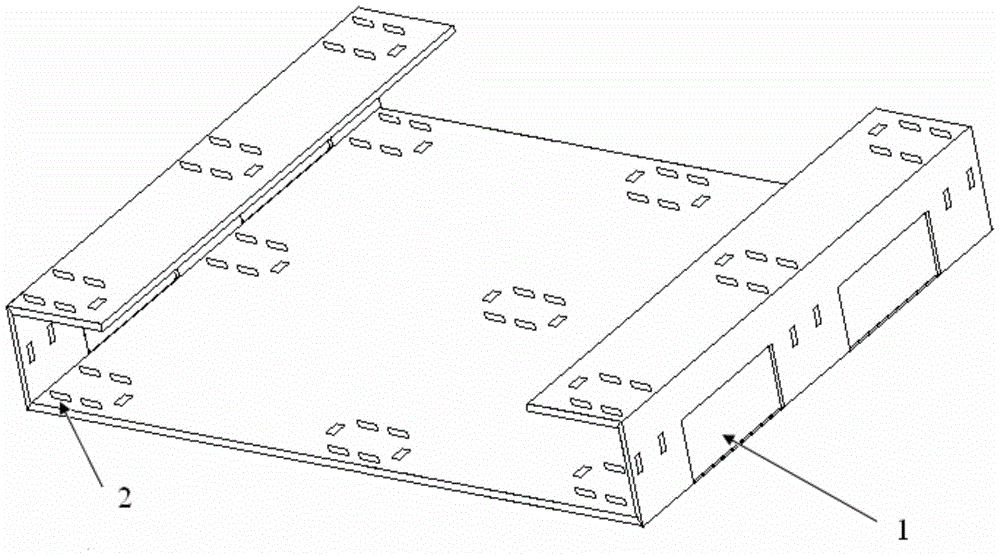

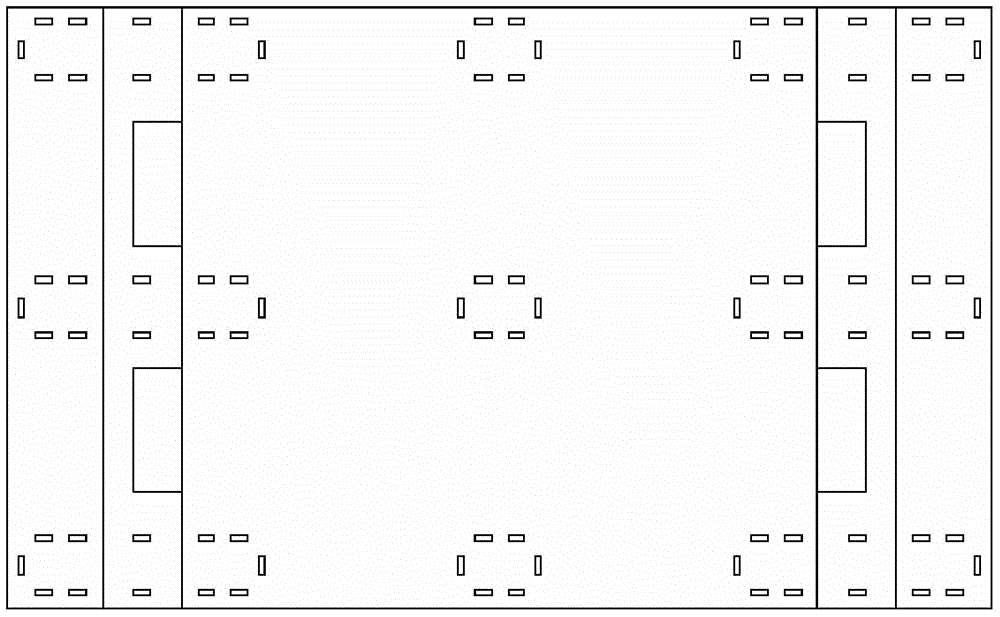

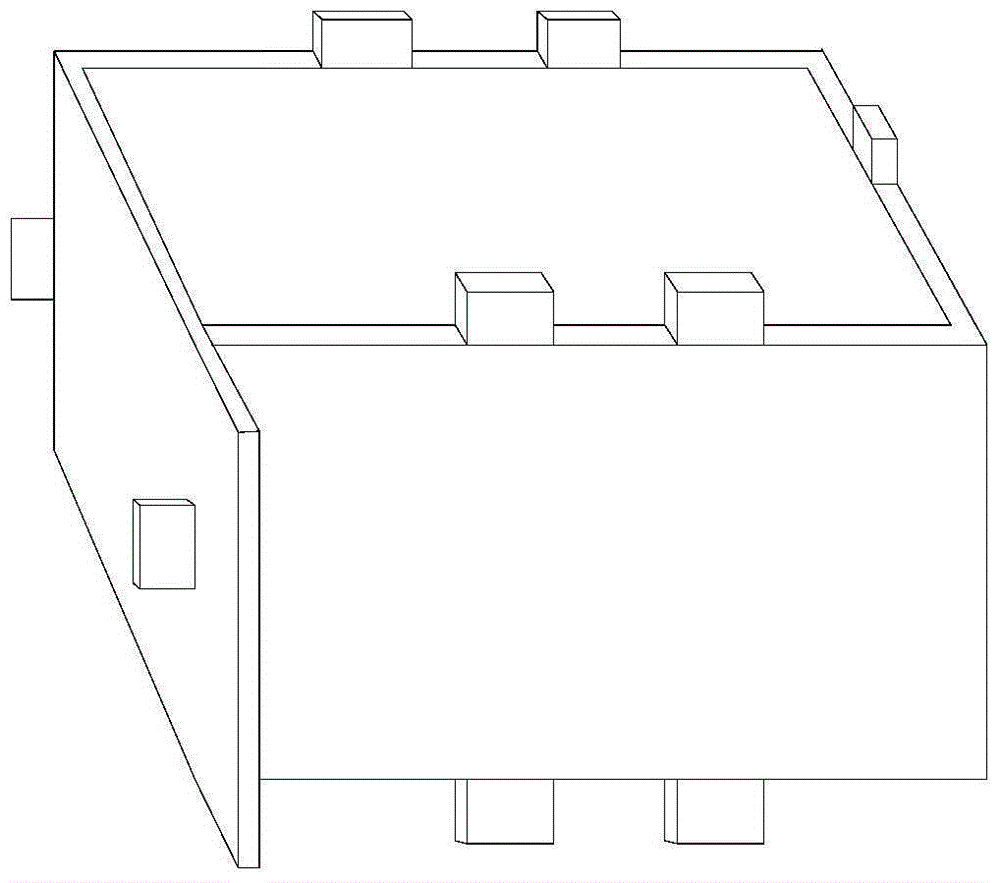

[0026] A full paper pallet comprising main components and auxiliary components such as figure 1 As shown, the main component is composed of a rectangular bearing panel formed by corrugated cardboard and two side panels and a bottom panel formed by folding at right angles. In the figure: two rectangular openings 1 (forklift inlet of the pallet), dimensions Unified rectangular socket 2, there are 90 rectangular sockets on the main component, which are used for plug connection and fixing of the main component and auxiliary components of the entire tray; figure 2 Shown is a schematic diagram of the plane expansion of the main component of the full-paper tray, and there are 90 rectangular jacks on the main component; Figure 3a and Figure 3b Shown are the three-dimensional schematic diagram and the planar development schematic diagram ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com