Large direct shear apparatus capable of achieving isotropic movement in three-dimensional space and test method thereof

A technology of three-dimensional space and direct shear instrument, which is applied in directions such as applying stable shear force to test the strength of materials, which can solve the problem of single shear direction, inability to realize large scale, and inability to truly reflect the mechanical properties of the interface between geosynthetics and filling soil. and other problems to achieve the effect of avoiding grid folding and pleating, large bearing capacity and high motion precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

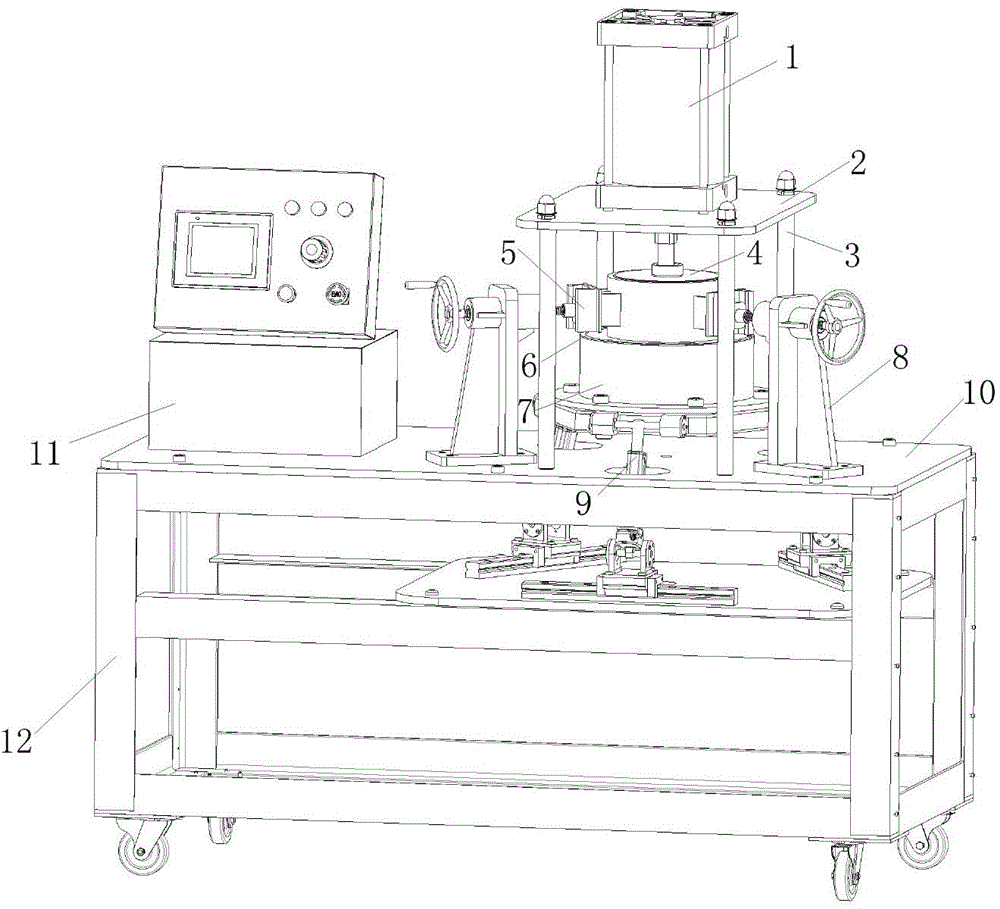

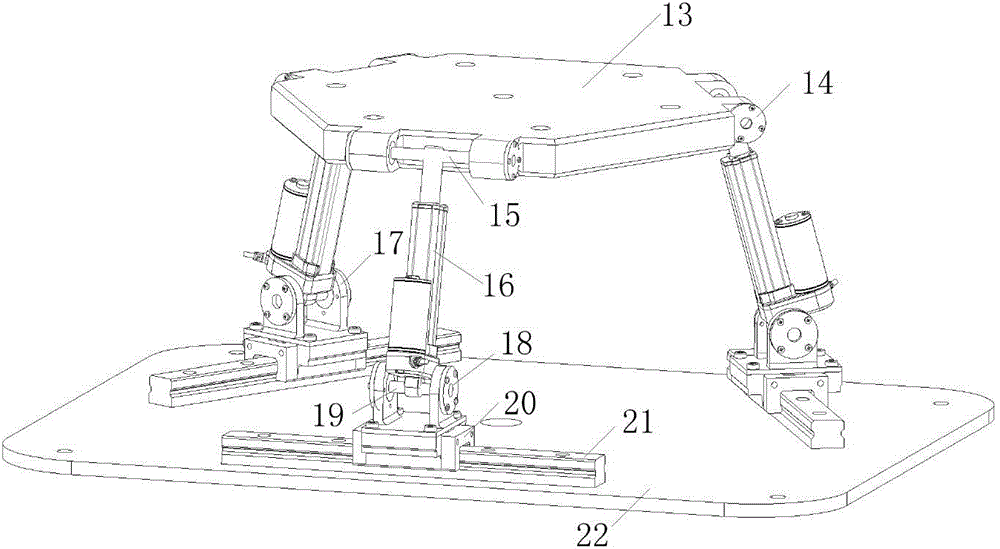

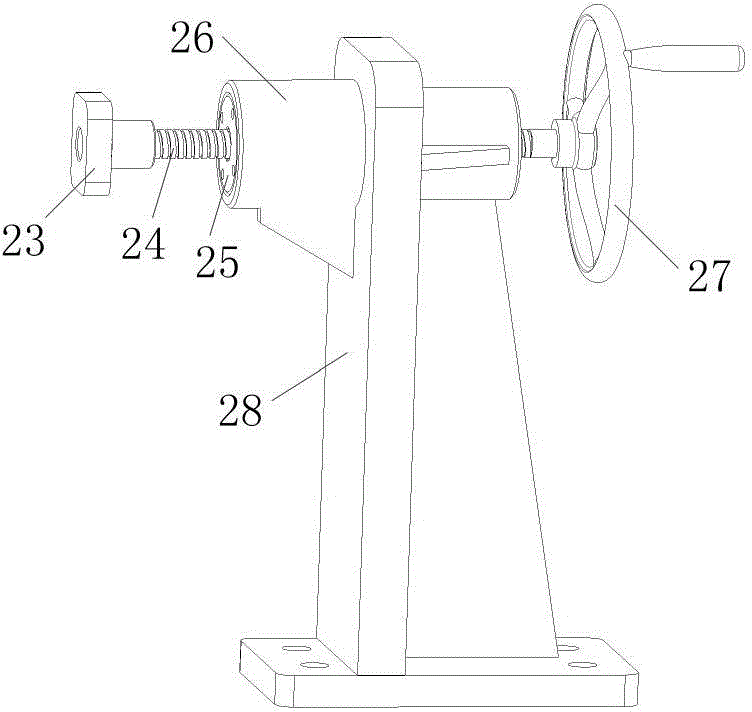

[0034] A large-scale direct shear instrument that can move in all directions in three-dimensional space, such as figure 1 As shown, it includes a loading device 1, a support plate 2, a support rod 3, a load plate 4, an upper shear box 5, a grid pressing piece 6, a lower shear box 7, a horizontal displacement restraint device 8, a motion actuator 9, a working Platform 10, electric control cabinet 11 and test bench 12.

[0035] The working platform is set on the test bench; the electric control cabinet, the horizontal displacement restraint device and the supporting device are all set on the working platform; the loading device is connected to the supporting device and set on the working platform through the supporting device; the motion actuator is set on the test bench on the frame; the bottom of the loading device is provided with a bearing plate; the upper shearing box, the grid pressing piece and the lower shearing box are arranged on the upper surface of the motion actuato...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com