Turnoff mechanism for sorting on two sides of linear sorting machine and use method of turnoff mechanism

A sorter, branch road technology, applied in the direction of sorting, conveyor objects, transportation and packaging, etc., can solve the problems of reducing the type and work efficiency of parcel sorting, limited number of sorting outlets, etc., to achieve important application value, sorting and other problems. The effect of picking type improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

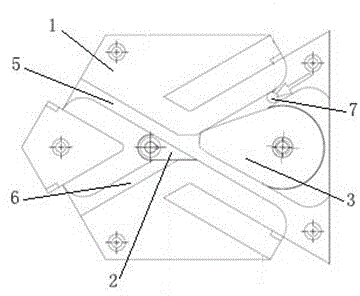

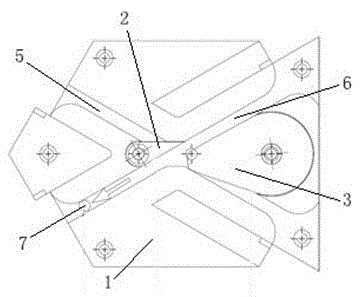

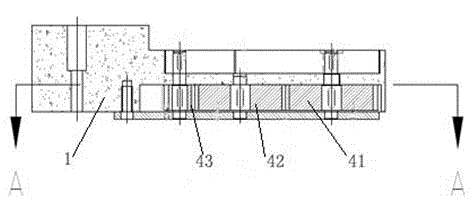

[0023] refer to figure 1 , figure 2 , image 3 and Figure 4 In this embodiment, a branch mechanism for sorting on both sides of a linear sorter includes a branch plate 1, a driven fork 2, an active fork 3 and a transmission mechanism 4, and the upper end surfaces of the branch plate 1 are connected to each other. The first guide groove 5 and the second guide groove 6 are arranged crosswise, the driven fork 2 and the active fork 3 are respectively rotated and arranged on the upper end surface of the diverge plate 1 through the rotating shaft, and the active fork 3 is driven by the transmission mechanism 4 The moving fork 2 swings on the branch board 1 in the same direction (the bottom of the branch board 1 is provided with a groove, and the transmission mechanism 4 is set in the groove), and the active fork 3 swings to close any one of the guide grooves. When there is one guide slot at the intersection, the driven fork 2 closes the guide slot at the other guide slot at the...

Embodiment 2

[0029] refer to figure 1 , figure 2 , Figure 5 and Figure 6 , a branch track mechanism for sorting on both sides of a linear sorter described in this embodiment, including:

[0030] The branch plate 1, the driven fork 2, the driving fork 3 and the transmission mechanism 4, the upper end surface of the branch plate 1 are provided with the first guide groove 5 and the second guide groove 6 intersecting each other, the driven fork 2 and the driving fork The forks 3 are respectively rotated and arranged on the upper end surface of the diverge plate 1 through the rotating shaft, and the active forks 3 drive the driven forks 2 to swing in the same direction on the diverge plate 1 through the transmission mechanism 4 (the bottom of the diverge plate 1 is provided with a concave slot, the transmission mechanism 4 is set in the groove), and when the active fork 3 swings to close any one of the guide slots at the intersection, the driven fork 2 closes the guide slot at the interse...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com