Automatic production apparatus for taking honey

A production device and bee technology, which is applied in the fields of honey collection, beekeeping, application, etc., can solve the problems of disturbing the normal ecology and living environment of bee colonies, economic benefits, and cumbersome problems, so as to maintain the original ecology of honey juice and Effects of brightness, solving the difficulty of extracting honey, and increasing economic income

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

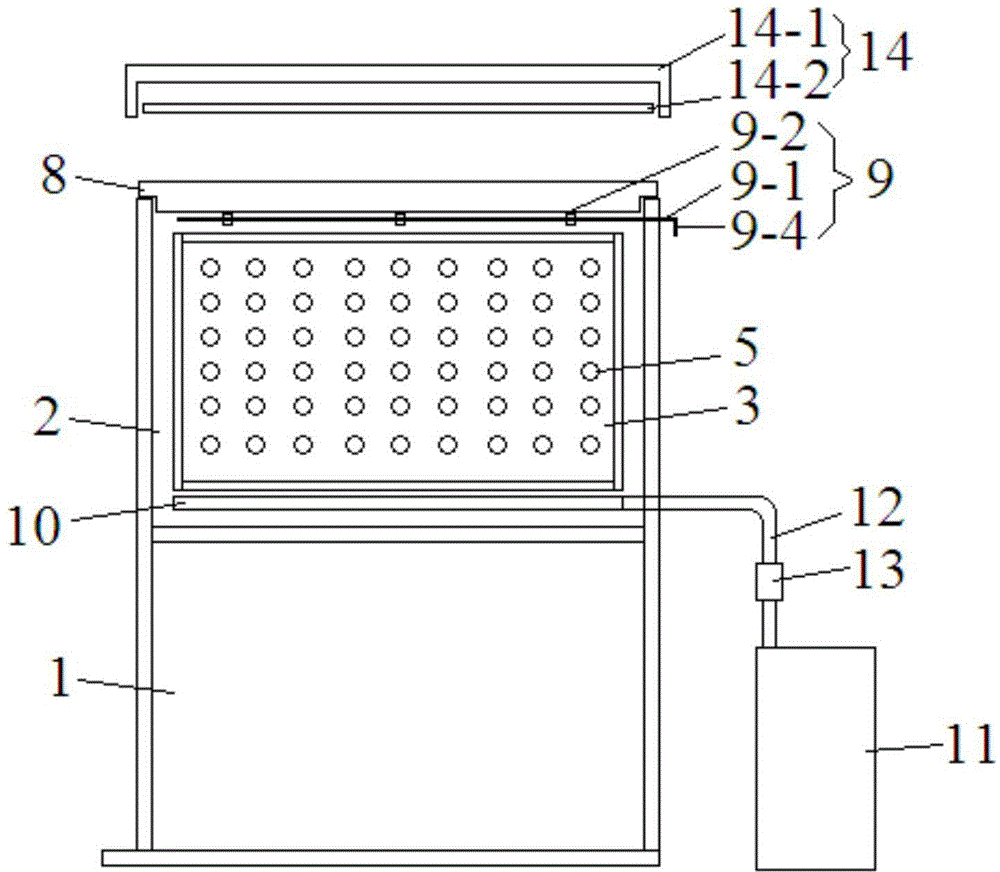

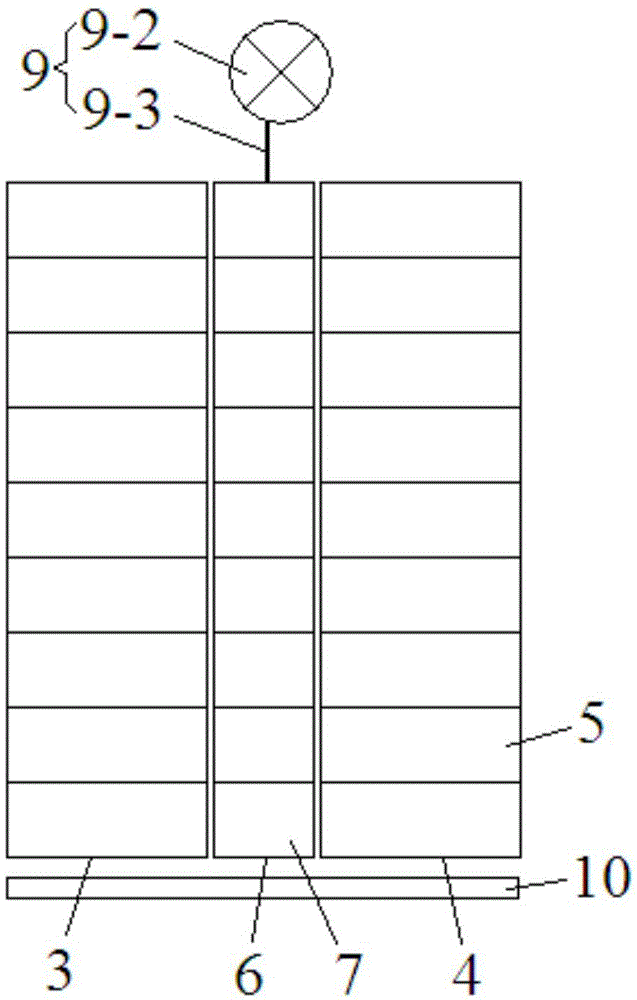

[0021] Referring to accompanying drawing, a kind of honeybee automatic honey-taking production device comprises nest box 1 and following box 2, and front and rear honeycomb 3,4 are respectively fixedly installed in following box 2, and front and rear honeycomb 3,4 respectively Corresponding cell hole arrays 5 are provided, and a central nest base sheet 6 is provided between the front and rear spleens 3 and 4, and a through hole array 7 corresponding to the cell hole array 5 is provided on the center nest base sheet 6; The top beam 8 in the box 2 is fixedly installed, and the lifting mechanism 9 is installed on the top beam 8, and the lifting mechanism 9 is connected with the center nest base sheet 6; The bottom of the sheet 6 is provided with a honey tank 10, and the outside of the box 2 is provided with a honey bucket 11, and a conduit 12 is connected between the honey tank 10 and the honey bucket 11, and a suction machine 13 is installed in the conduit 12.

[0022] In the pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com