Attached type lifting device for cleaning tall and big-space of cleaning chamber

A high-space, clean-room technology, applied in construction, building structure, processing of building materials, etc., can solve problems such as efficiency and safety cannot be guaranteed, and achieve the effect of avoiding the danger of falling, high efficiency and improving efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

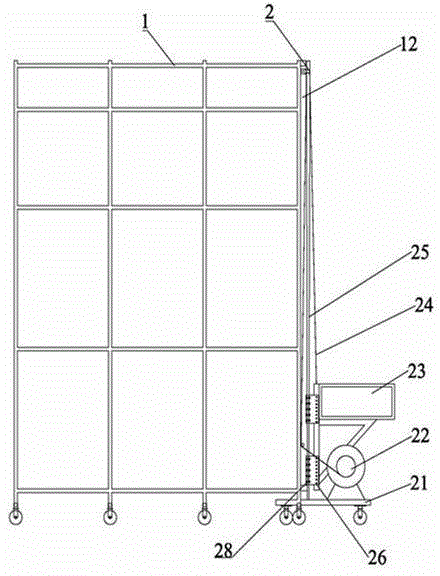

[0010] Depend on figure 1 As can be seen, the present invention includes a mobile scaffold 1, a mobile material lifting device 2, and the mobile material lifting device 2 includes a mobile base 21, a moving track 25, a transport shelf 23, a hoist 22, a traction wire rope 24, and connecting casters 28 , the connecting plate 26, the upper surface of the mobile base 21 is fixed with a moving track 25 and a hoist 22, the upper and lower top ends of the moving track 25 are fixedly connected with the mobile scaffold 1 through the movable connection device 12, and the left and right sides of the moving track 25 Connecting casters 28 are respectively provided; the connecting casters 28 are connected with the transport shelf 23 through the connecting plate 26; the traction wire rope 24 is fixed above the transport shelf 23; The output end is connected, and the fixed pulley 27 is fixed on the mobile scaffold 1.

[0011] Preferably, at least three pairs of connecting casters 28 are fixe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com