A tower crane and its operation method

A technology of tower cranes and main towers, applied in the field of construction machinery, can solve problems such as shortened service life, pollution, hidden safety hazards, etc., and achieve the effect of stable force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Combine below Figure 1-3 The present invention will be described in detail.

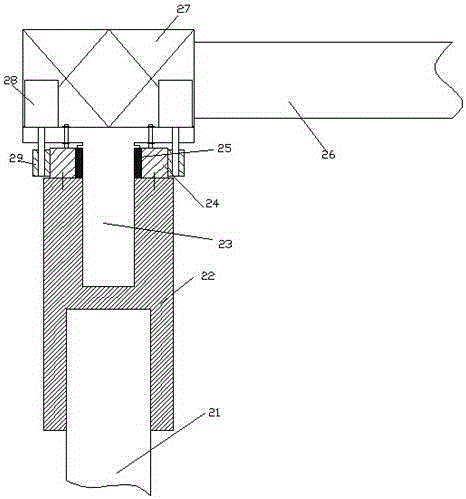

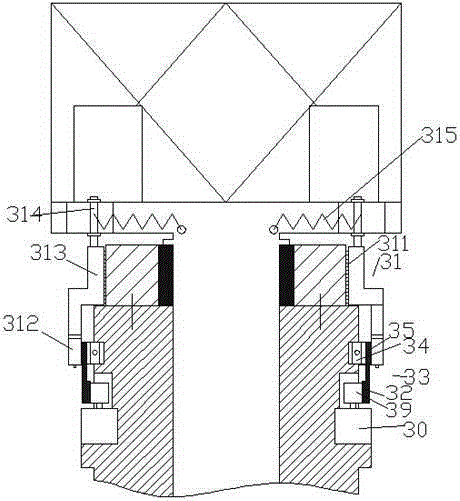

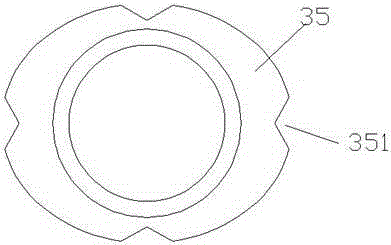

[0016] The tower crane device according to the embodiment includes a main tower body 21, a sleeve frame 22 sleeved on the top of the main tower body 21, a gear plate 24 fixedly installed on the top of the sleeve frame 22, and a turntable 27 rotatably matched with the gear plate 24. And the rotating arm 26 that is fixedly connected with the rotating frame 27, the rotating driving motor 28 is fixedly arranged on the rotating frame 27, and the rotating driving motor 28 is driven by the meshing of the pinion 29 fixedly connected with it and the gear plate 24 The rotating frame 27 and the rotating arm 26 rotate.

[0017] Optionally, the bottom of the turntable 27 is provided with a long axis portion 23 extending downwards to pass through the inner hole of the gear plate 24 and be inserted into the sleeve 22 .

[0018] Optionally, the upper part of the long axis part 23 is connected with the gear...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com