Refrigerator evaporator with efficient temperature changing chamber

A refrigeration room evaporator, variable greenhouse technology, applied in the direction of evaporator/condenser, household refrigerator, lighting and heating equipment, etc. The effect of increasing the effective length and improving the heat exchange efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below according to the accompanying drawings and in conjunction with the embodiments.

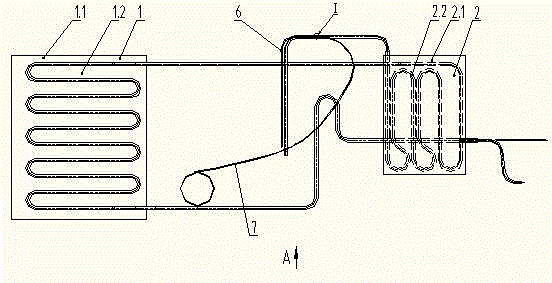

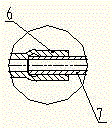

[0016] The refrigerator evaporator with high-efficiency variable temperature room shown in the accompanying drawing includes a refrigerating room evaporator 1, a variable room evaporator 2, a capillary tube 7, and a transition tube 6; the refrigerating room evaporator 1 includes a refrigerating room aluminum plate 1.1, and a refrigerating room heat exchange tube 1.2, the heat exchange tube 1.2 of the refrigerator room is fixed on the aluminum plate 1.1 of the refrigerator room after multiple rounds of bending; It is fixed on the aluminum plate 2.1 of the variable room; one end of the heat exchange tube 1.2 of the refrigerating room and the heat exchange tube 2.2 of the variable room are connected together;

[0017] The variable room aluminum plate 2.1 is provided with a groove corresponding to the variable room heat exchange tube 2.2, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com