Detachable triangular supporting system for ensuring horizontal supporting and installing and adjusting method

A technology of horizontal support and triangular support, which is applied in the direction of scaffolding supported by house structure, house structure support, house structure support, etc. It can solve the problem that the support height of the triangular support frame cannot be guaranteed, it is easy to affect the re-use of the triangular support frame, and affect the construction efficiency, etc. problems, to achieve the effect of improving installation and removal efficiency, reliable sliding, and improving installation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

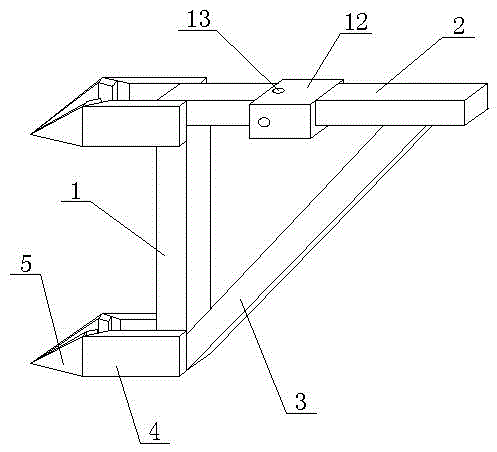

[0040] Such as Figure 1~Figure 7 As shown, the detachable triangular support system to ensure horizontal support described in this embodiment includes a tripod and at least two plug-in mechanisms arranged on the tripod. The tripod includes a vertical bar 1, a horizontal bar 2 and a diagonal bar 3. The vertical bar 1, the horizontal bar 2 and the inclined bar 3 form a right-angled triangle, the plug-in mechanism is fixed on the vertical bar 1, and all the plug-in mechanisms are located in the same vertical direction.

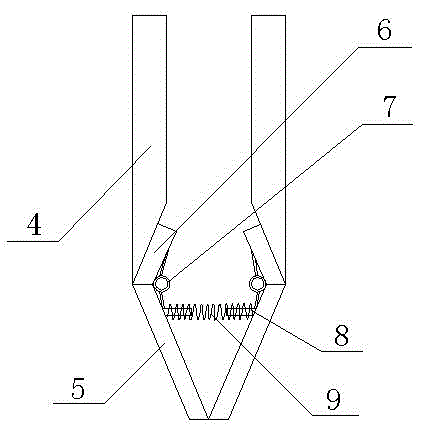

[0041] The plug-in mechanism of the present embodiment comprises two support plates 4 and two guide plates 5, and the two support plates 4 are vertically fixed on the vertical bar 1, and the two support plates 4 are parallel to each other; the guide plates 5 are right-angle plates, and the guide plates 5 The vertical side is parallel to the support plate 4, and the length of the vertical side is equal to the height of the support plate 4, the bottom edge of the ...

Embodiment 2

[0055] On the basis of Embodiment 1, this embodiment further defines the structure of the movable plate 6: the height of the movable plate 6 is equal to the height of the support plate 4, and the bottom edge of the movable plate 6 is aligned with the bottom edge of the support plate 4 Flat, so that when the movable plate 6 slides, the problem that both ends will not be lifted, and avoid affecting the sliding smoothness of the movable plate 6.

Embodiment 3

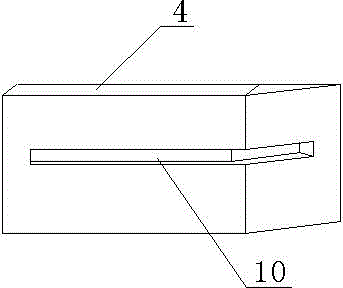

[0057] In this embodiment, on the basis of Embodiment 1, the position structure of the guide groove 10 is defined as follows: the distance from the guide groove 10 to the top edge of the support plate 4 is 1 to 2 times the distance from the guide groove 10 to the bottom edge of the support plate 4 times. Because the guide plate 5 is a right-angled triangle structure, its center of gravity is located below the horizontal bisector of the support plate 4, after the position of the guide groove 10 is limited, it can ensure that the direction of motion of the guide plate 5 is basically consistent with the direction of the force, so that the guide plate 5 and the movable plate 6 sliding is more stable and reliable.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com