An adjustable two-stage rotary purification device

A purification device and adjustable technology, applied in chemical instruments and methods, semi-permeable membrane separation, permeation/dialysis water/sewage treatment, etc., can solve problems such as membrane mask pollution, improve membrane permeation flux, and solve concentration differences Polarization and membrane fouling problems, effects of improving separation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

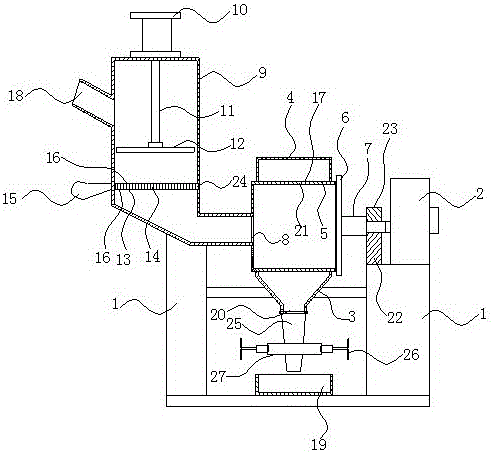

[0023] Below, in conjunction with accompanying drawing and specific embodiment, the present invention is described further:

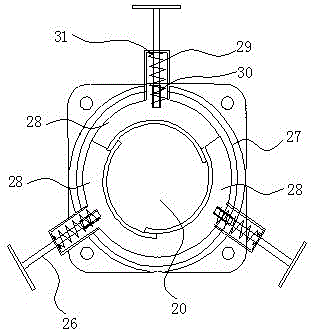

[0024] Such as Figure 1-2 As shown, it is an adjustable two-stage rotary purification device of the present invention, including a fixed frame 1, a housing, a rotating cylinder 5, a filter cylinder 9 and a first motor 2, and the housing, the filter cylinder 9 and the first The motors 2 are all installed on the fixed frame 1, and the rotating cylinder 5 is horizontally rotatably installed in the housing, and a plurality of first filter holes 21 are arranged on the circumferential wall of the rotating cylinder 5. A first membrane member 17 is set on the outer peripheral wall, a liquid outlet 20 is formed at the bottom of the housing, an end cover 6 is detachably connected to the right end of the rotating cylinder 5, and the end cover 6 is fixedly connected with a The first rotating shaft 7, the first rotating shaft 7 is connected with the output shaft o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com