Submersible linear motor and rotor thereof

A technology of linear motors and movers, applied in the direction of electric components, electromechanical devices, electrical components, etc., can solve problems such as lack of replenishment of lubricating oil, failure to form a protective oil film, wear of stators of submersible linear motors, etc., to improve the use of Lifespan, friction-relieving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

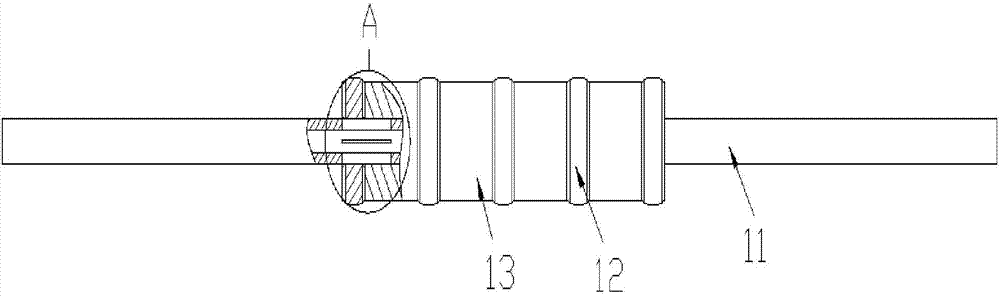

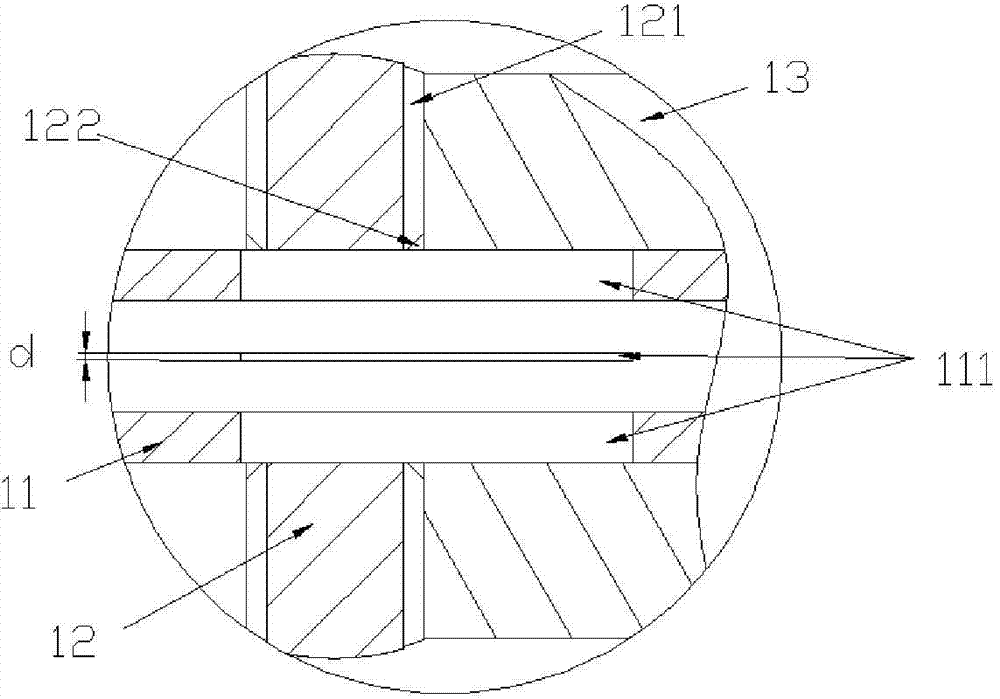

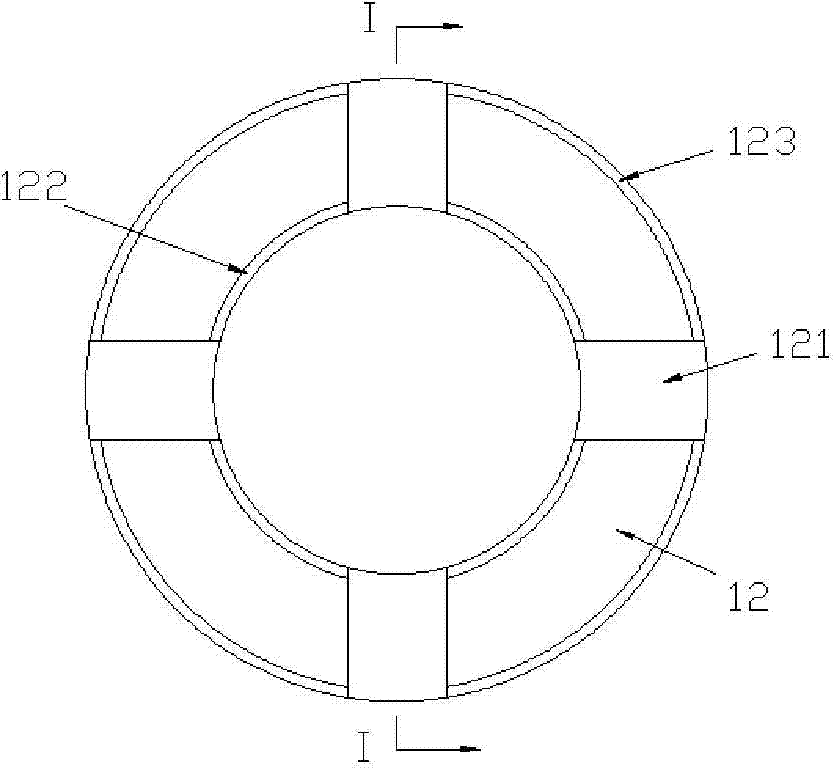

[0023] Such as Figure 1-3 As shown, the mover of the submersible linear motor in this embodiment includes the mover inner tube 11, the wear-resistant magnetic conducting ring 12 and the magnet 13 that are sleeved on the mover inner tube 11 at intervals, and the mover inner tube 11 is Hollow structure, and an oil passage 111 is provided on the pipe wall; an oil guide groove 121 is opened on the end surface of the wear-resistant magnetic conducting ring 12, and the oil passage 111 and the oil guide groove 121 are in communication with each other. By setting the oil passage 111 on the tube wall of the inner tube 11 of the mover, an oil guide groove 121 is set on the end surface of the wear-resistant magnetic permeable ring 12, and the oil passage 111 and the oil guide groove 121 are connected to each other, so that it can be connected with the inner surface of the stator. The lumen of the tube forms a circulating lubricating oil circuit. When the mover of the submersible linear ...

Embodiment 2

[0027] Such as figure 1 , 2 , 3, and 5, the submersible linear motor of this embodiment includes a stator 2, a mover 1 sleeved in the stator 2, and seals 3 arranged at both ends of the stator 2. The stator 2 includes a stator inner tube 21 and a stator coil 22 sleeved on the stator inner tube 21; the mover 1 includes a mover inner tube 11, and wear-resistant and magnetically conductive coils sleeved on the mover inner tube 11 at intervals. Ring 12 and magnet 13, the inner tube 11 of the mover is a hollow structure, and an oil passage 111 is provided on the pipe wall; an oil guide groove 121 is opened on the end surface of the wear-resistant magnetic conducting ring 12, and the oil passage 111 communicates with the oil guiding groove 121 . By setting the oil passage 111 on the tube wall of the inner tube 11 of the mover, an oil guide groove 121 is set on the end surface of the wear-resistant magnetic permeable ring 12, and the oil passage 111 and the oil guide groove 121 are ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Gap width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com