Integrated concrete pouring plastic formwork

A plastic formwork and concrete technology, which is applied in the direction of formwork/formwork components, formwork/formwork/work frame, formwork/formwork/work frame connectors, etc., can solve the problem of low reuse rate, high maintenance cost, wood Problems such as large usage, to achieve the effect of improving utilization efficiency, reducing the number of connections, and reducing intermediate consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

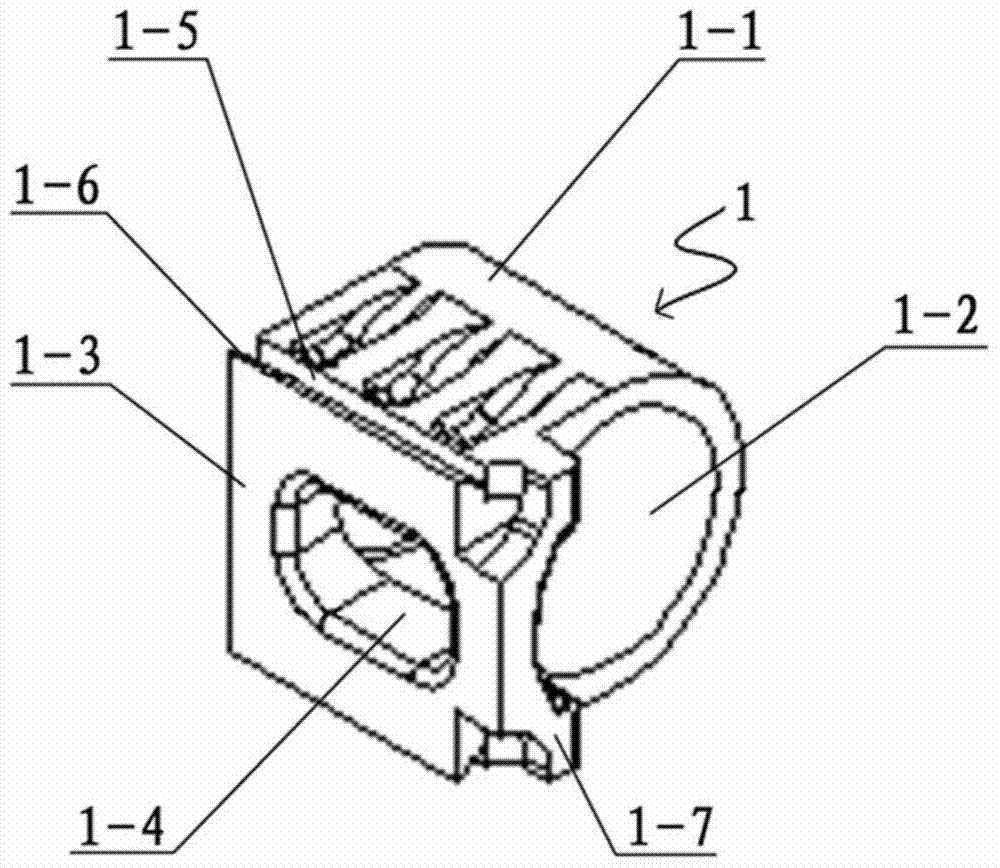

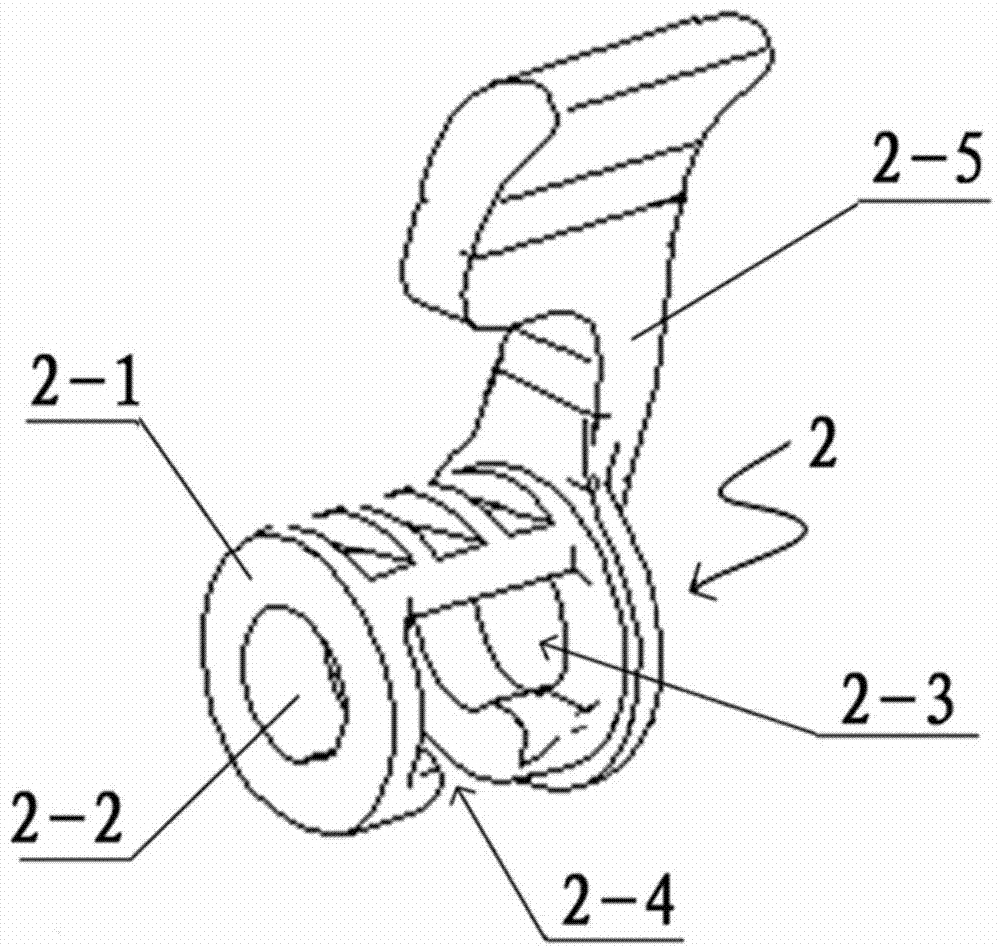

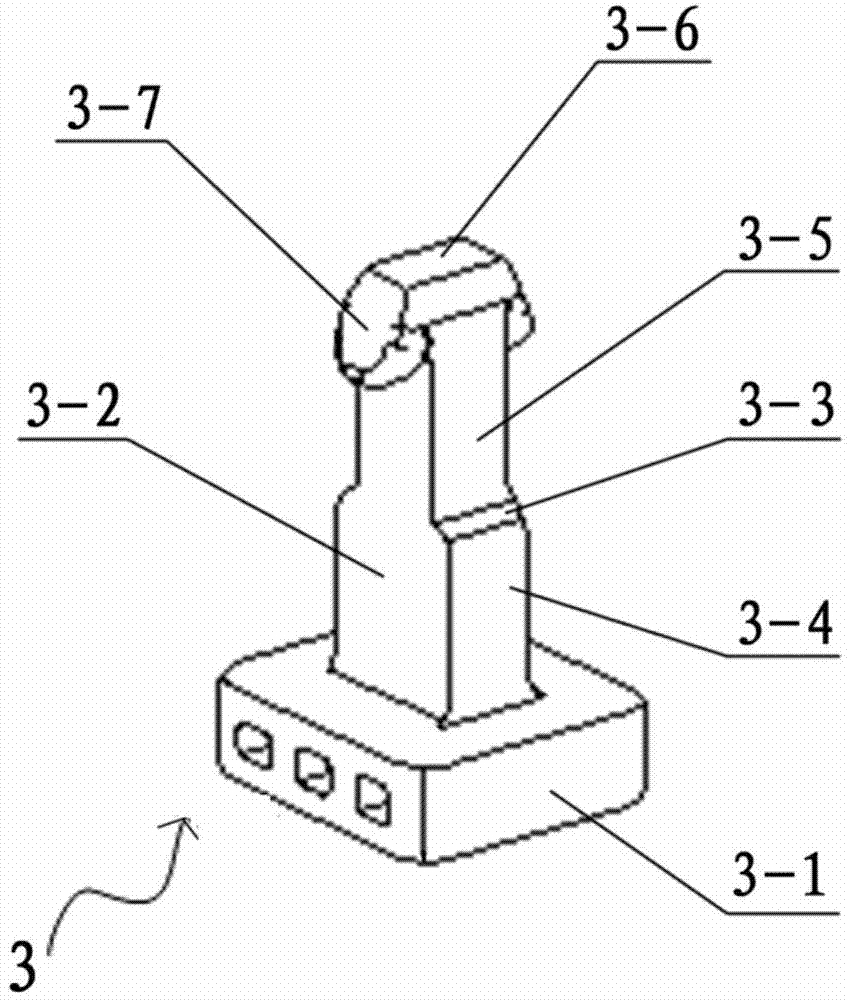

[0034] The integrated concrete pouring plastic formwork provided by the present invention includes flat plate series formwork, internal corner series formwork, male angle series formwork, internal and external corner plastic formwork and connecting components; the flat plate series formwork is mainly used to construct the plane of a building, which includes a flat plate Plastic formwork and strip plastic formwork; Yinjiao series formwork is mainly used to construct the inner concave corner of the building, which includes Yinjiao plastic formwork and three Yinjiao plastic formwork; Yangjiao series formwork is mainly used to construct the outer convex corner of the building, It includes plastic formwork with male corners and plastic formwork with three male corners; the plastic formwork with male and female corners is mainly used to construct the beam frame of the building; the connecting member is used to realize the connection between the template and the template, which include...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com