Device for metering fine-grained filling material into packaging containers

A technology for packaging containers and fillings, applied in the field of equipment for dosing fine-grained fillings into packaging containers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

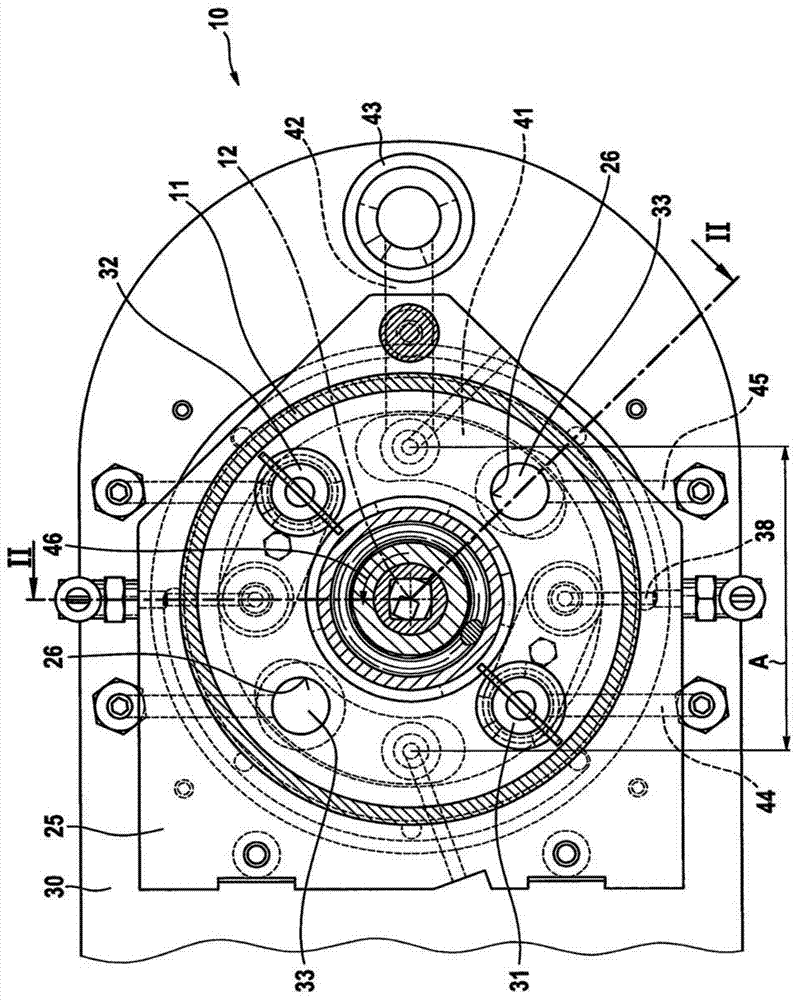

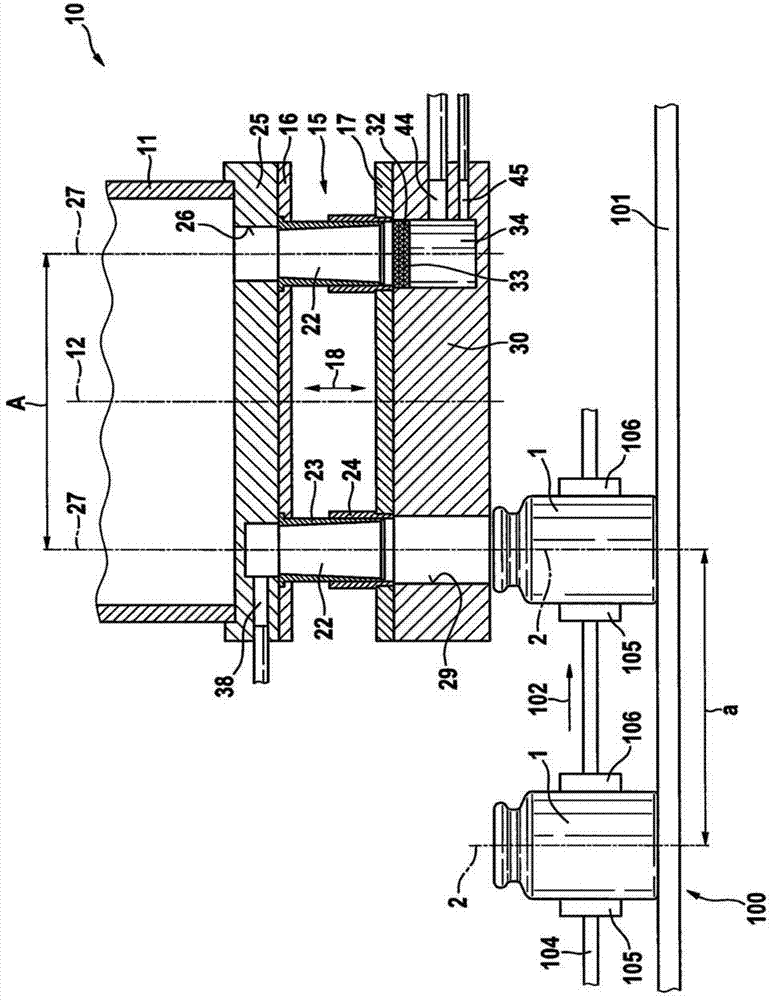

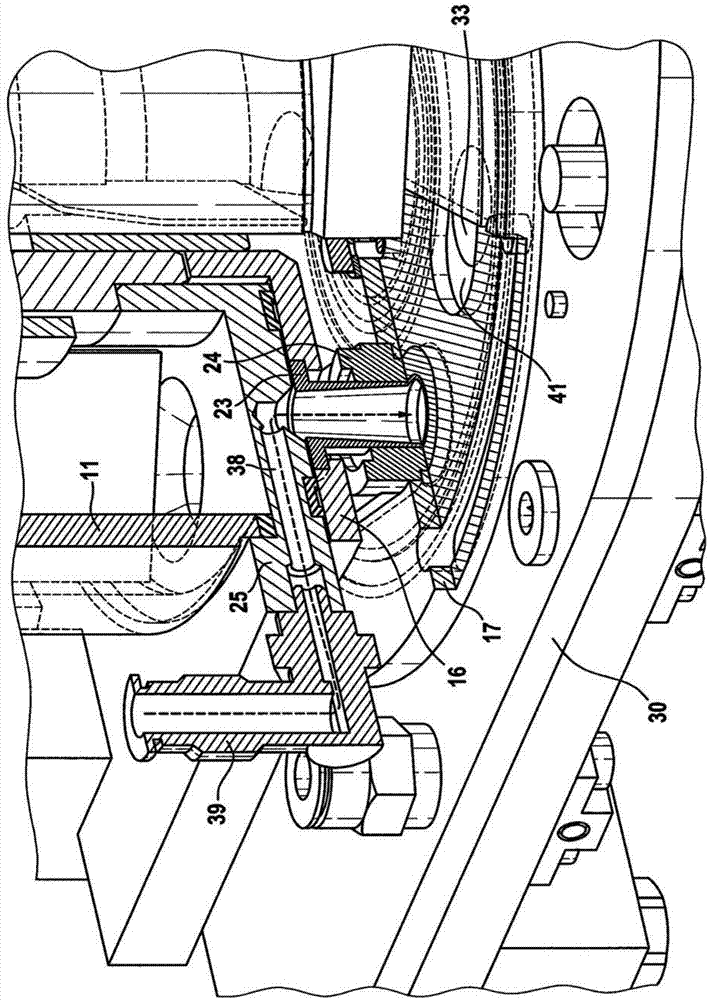

[0026] exist figure 1 and 2 The device 10 for dosing fine-grained medicaments shown in the packaging container 1 is the same as only in figure 1 A conveying device 100 for packaging containers 1 , which is visible in FIG. 2 , is arranged substantially below the device 10 and is formed linearly in the area of the device 10 . The drug is preferably, but not limited to, so-called granules or microspheres, and the packaging container 1 is, for example, a glass vial, which after filling is hermetically closed with a cap, not shown.

[0027] The conveying device 100 comprises, by way of example and without limitation, a bottom rail 101 arranged in a stationary manner, along which the packaging containers 1 slide vertically in the direction of the arrow 102 during their transport. Furthermore, a conveyor belt 104 driven by a drive (not shown) can be seen for the periodic transport of the packaging containers 1 by means of receptacles 105 , 106 between which the packaging containe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com