Improved electric current sensing and management system for electrolytic plants

A management system, technology for electrolytic workshops, applied in the field of metallurgical systems and improvement of the operating conditions of electrolytic cells and/or electrolytic chambers, capable of solving problems such as poor morphology, uncoordinated cathode weight, lowering, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

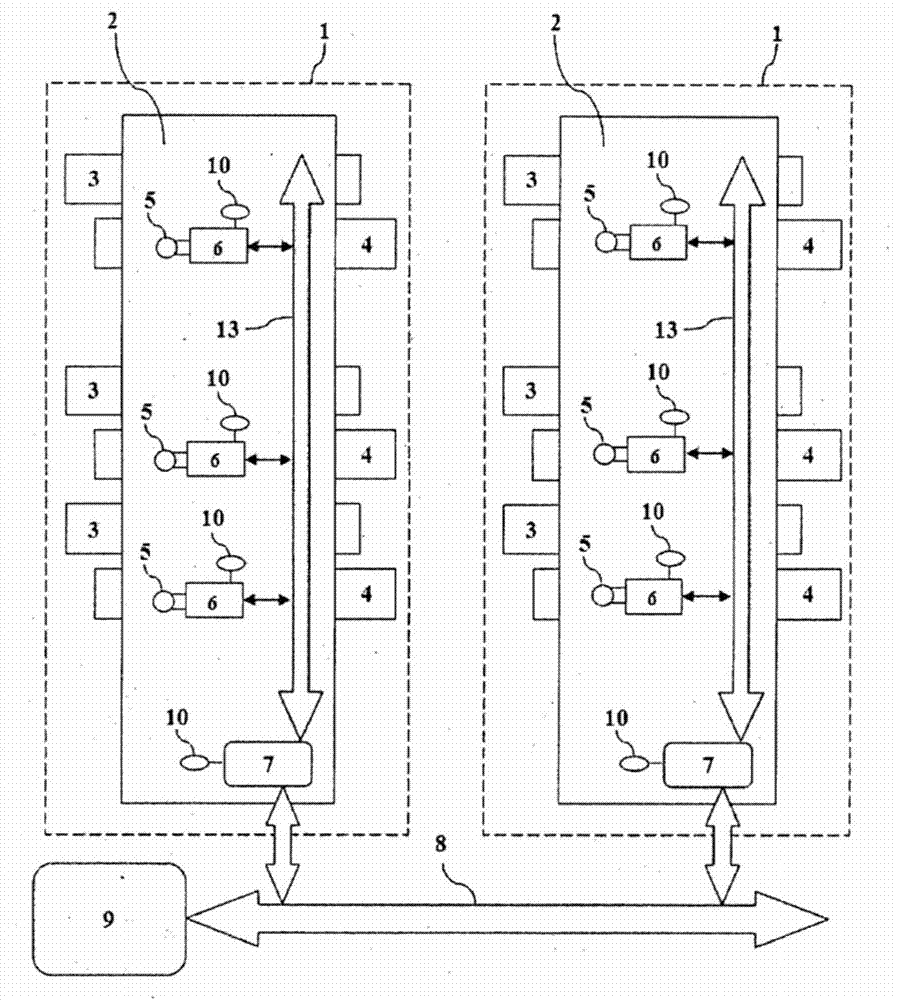

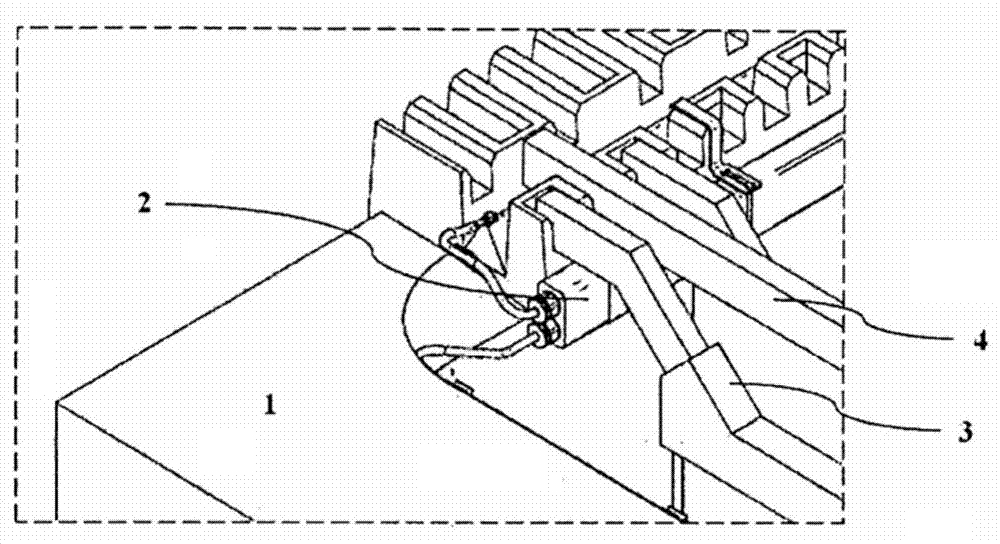

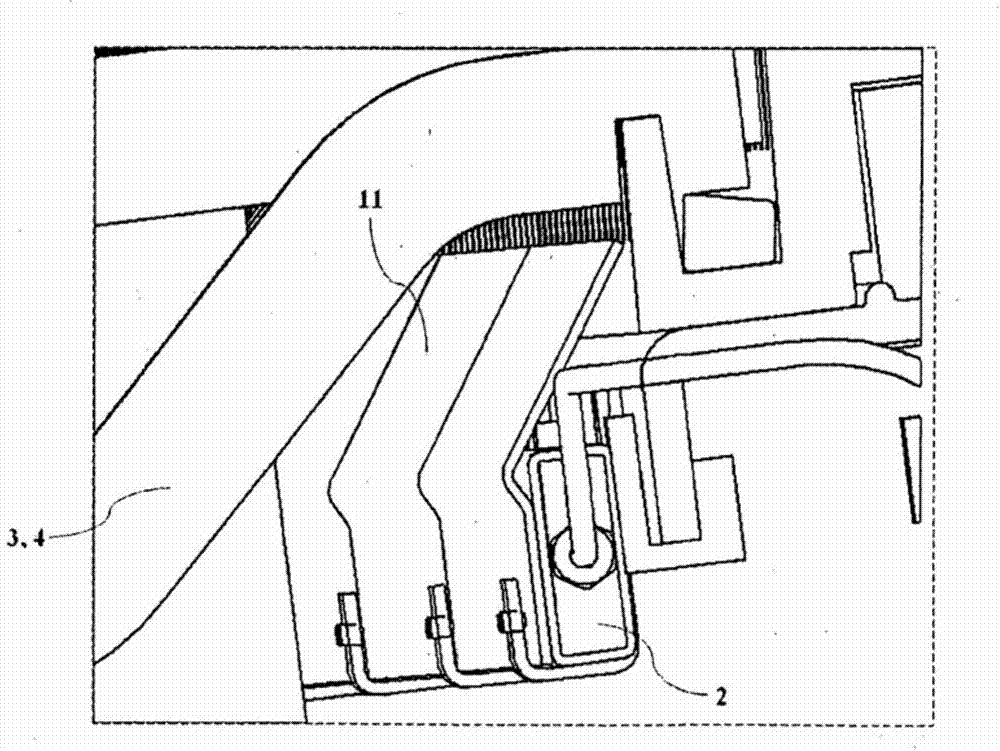

[0059] Such as figure 1 As shown, an embodiment of the invention comprises an electrolytic cell (1) comprising a plurality of cathodes (4) and anodes (3) arranged in an alternating manner with respect to each other within an electrolytic medium. In the case of the present invention, the cathode ( 4 ) and anode ( 3 ) correspond to plates arranged parallel to each other. Near each plate, preferably each cathode plate, a sensor device (5) is arranged on the sensor strip (2) or ECM strip. Such a sensor strip, which is part of the ECM system of the present invention, is positioned adjacent to the current strip output (or input) from (to) the cathode (or anode) plate. Such a sensor strip and such a sensor arrangement do not require direct contact with the electrodes. In addition, the ECM strip (2) can be positioned at one of many locations in the electrolytic cell (1), such as within the cell wall, within the cell (e.g. Figure 2 to Figure 10 shown), within tank top appendages / in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com