Pitching slewing mechanism linked with horizontal slewing for fire monitor

A technology of horizontal rotation and slewing mechanism, which is applied in fire rescue and other directions, can solve the problems affecting the hydraulic characteristics of the fire monitor flow channel, affecting the spray performance of fire monitors, and increasing the volume of fire monitors, achieving compact structure, improved spray performance, and optimized The effect of hydraulic properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

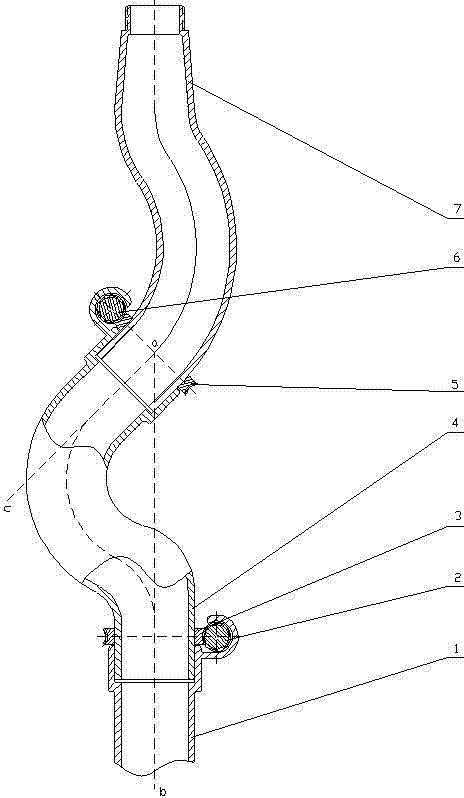

[0011] The fire monitor pitching and rotating mechanism linked with the horizontal rotation of the present invention is composed of a gun base 1, a horizontal rotating worm 2, a horizontal rotating worm wheel 3, a lower bend 4, a pitching rotating worm 5, a pitching rotating worm 6, and an upper bending 7. As shown in the figure.

[0012] The horizontal rotary worm 2 is installed on the gun base 1, the horizontal rotary worm gear 3 is inserted into one end of the lower elbow 4 and fixed, the end of the lower elbow 4 extends into the gun base 1, and the horizontal rotary worm 2 and the horizontal rotary worm gear 3 meshing; the pitching rotary worm 6 is installed on the lower elbow 4, the pitching rotary worm gear 5 is inserted into one end of the upper elbow 7 and fixed, the end of the upper elbow 7 extends into the lower elbow 4, and the pitching rotary worm 6 and The pitching and turning worm gear 5 is engaged.

[0013] When the present invention is in use, the pitching and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com