Fixture for measuring thickness of FPC (Flexible Printed Circuit) antenna die cutting part

A technology of die-cut parts and antennas, applied in the direction of mechanical thickness measurement, etc., can solve the problems of long measurement time, low efficiency, and increasingly high requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

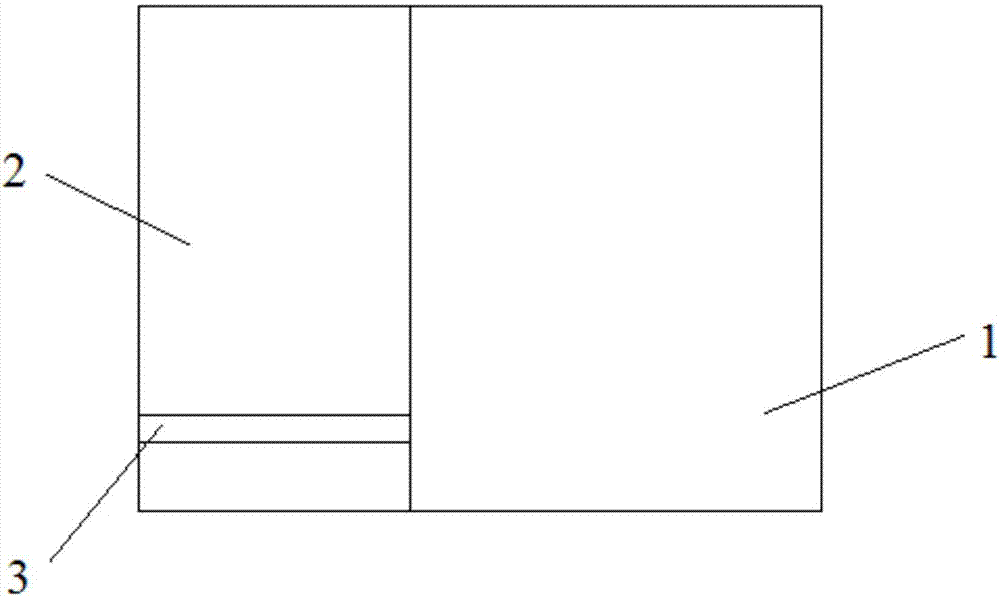

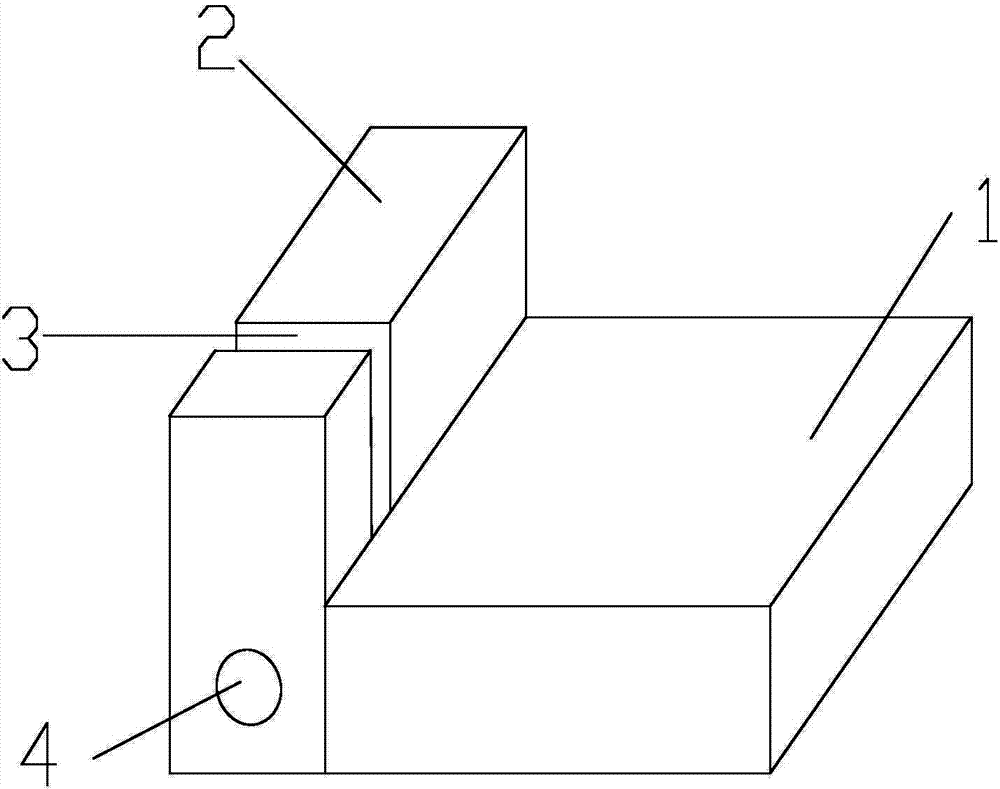

[0014] Such as Figure 1~2 As shown, the jig for measuring the thickness of FPC antenna die-cutting parts includes a detection table 1, a raised detection frame 2 is provided on one side of the detection table, and a detection slot 3 is provided on the detection frame 2. The width of the detection slot 3 is the same as The thickness of the FPC antenna die-cut parts is consistent; the detection frame 2 is set separately from the detection table 1, and the detection frame 2 is fixed on the side of the detection table 1 by bolts 4, and the height of the detection frame protruding from the detection table is adjusted to adjust the detection frame. The depth of the groove.

[0015] When testing, pass the FPC antenna die-cut part through the detection slot. If it is too thin or too thick, the speed when passing through the detection slot will be affected, so that it can quickly determine whether the thickness of the FPC antenna die-cut product meets the requirements. Require. At t...

Embodiment 2

[0017] The jig for measuring the thickness of the FPC antenna die-cut piece includes a detection table. A raised detection frame is provided on one side of the detection table. There is a detection slot on the detection frame. The width of the detection slot is consistent with the thickness of the FPC antenna die-cut part; The detection frame and the detection table are integrally arranged.

[0018] The depth of the detection groove is greater than or equal to the height of the die-cut part of the FPC antenna.

[0019] When testing, pass the FPC antenna die-cut part through the detection slot. If it is too thin or too thick, the speed when passing through the detection slot will be affected, so that it can quickly determine whether the thickness of the FPC antenna die-cut product meets the requirements. Require. At the same time, the depth of the detection groove can be adjusted, so that it can be used with a variety of different FPC antenna die-cut products.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com