Novel axle shaft flange

A shaft flange, a new type of technology, applied in the field of auto parts, can solve the problems of inability to realize the overload protection function of the car, unfavorable safe driving, and low safety performance, and achieve the effect of eliminating the hidden danger of overload, facilitating processing and production, and striving for simplicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

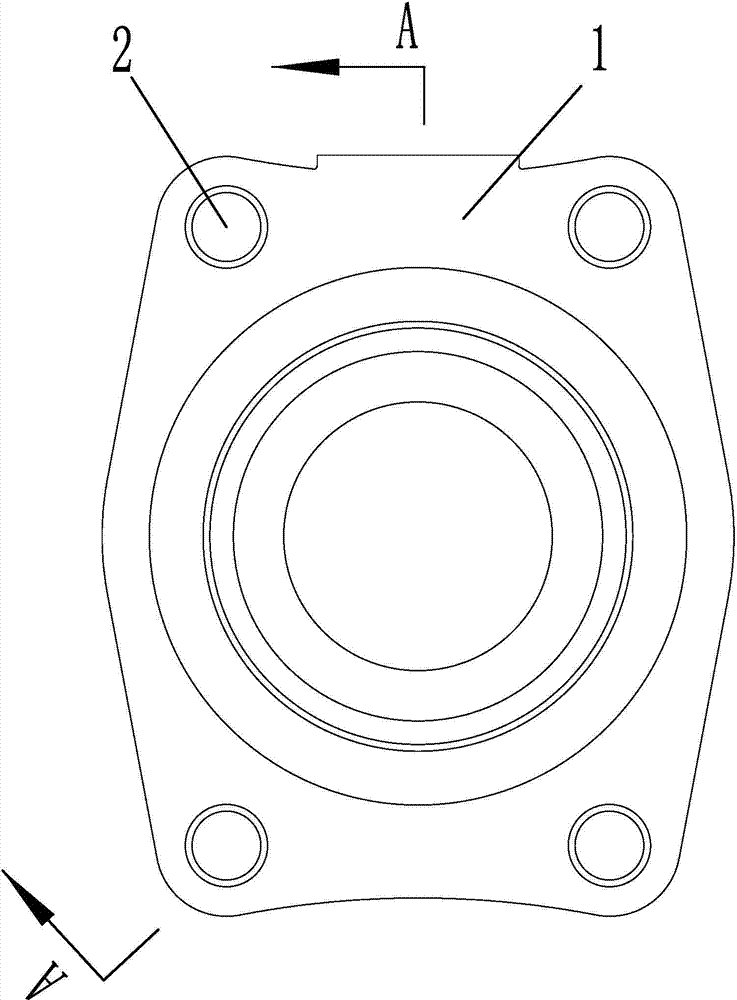

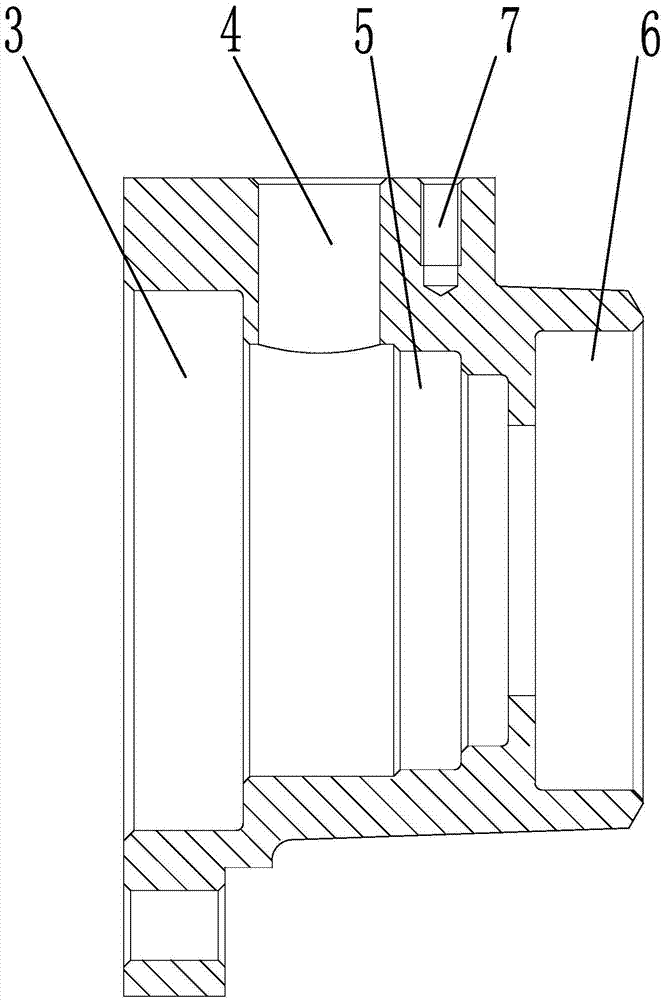

[0010] Such as figure 1 , 2 As shown, the technical solution adopted by the present invention is: a new type of semi-axis flange, with a brake assembly hole 2 respectively provided at the four top corners of the disc body 1, and the central position of the disc body 1 from left to right An oil seal hole 3, a sensor mounting hole 4, a bearing hole 5, and a bridge base joint hole 6 are provided in sequence. The sensor mounting hole 4 passes through the upper surface of the disc body 1 to contact the outside world. On the right side of the sensor mounting hole 4, a Sensor thread fixing hole 7.

[0011] Through the above settings, the present invention first installs the sensor in the sensor installation hole 4 and fixes it through the sensor threaded fixing hole 7 when assembling. Then the bearing and the oil seal are respectively installed in the bearing hole 5 and the oil seal hole 3 in sequence, and finally the installed disc body 1 is combined with the bridge blank through ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com