An installation method for installing prefabricated bay windows on laminated wall panels

An installation method and technology of superimposed walls, applied in the processing of walls, building materials, building components, etc., can solve the problems that cannot be directly adopted, complicated procedures, troublesome procedures, etc., and achieve reduced on-site workload, simple transportation, and smooth flow Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

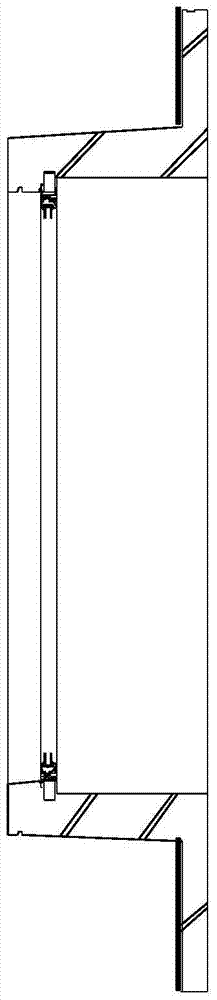

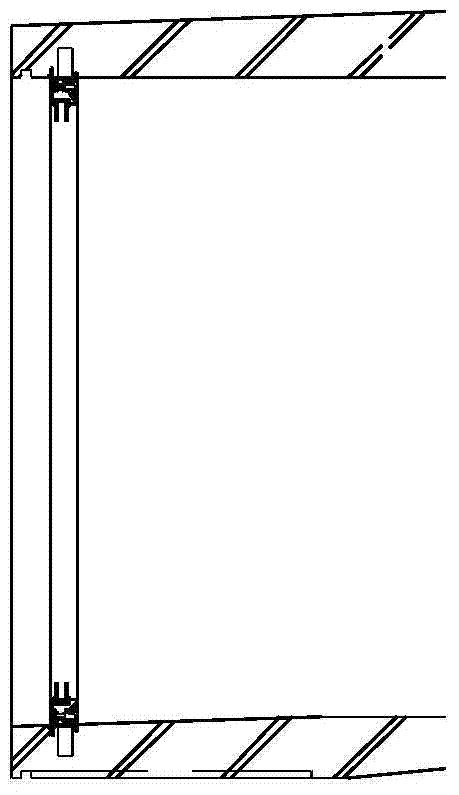

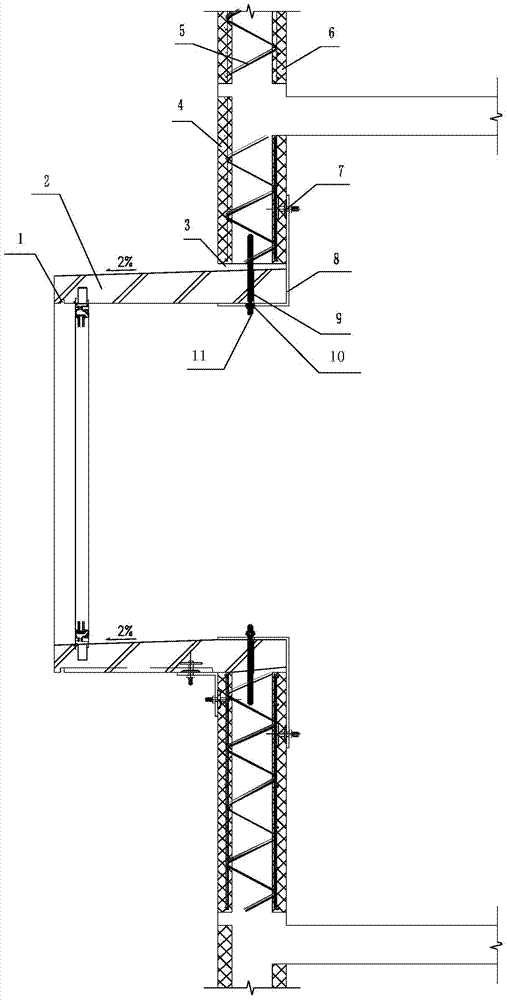

[0047] The structure of the present invention will be described in further detail below in conjunction with the drawings.

[0048] As shown in the picture, a prefabricated bay window structure installed on a laminated wall panel,

[0049] The prefabricated bay window 2 is composed of prefabricated rectangular cement board bay window upper eaves, bay window lower eaves, bay window left facade, and bay window right facade.

[0050] The upper eaves of the bay window have a slope of 2-3% outward, and the lower part of the upper eaves of the bay window has a linear drip groove 1; the upper eaves of the bay window have a slope of 2-3% outwards. There is a linear drip trough 1 at the lower part of the lower eave of the bay window; there is a linear drip trough 1 on the left side of the bay window and the lower part of the right side façade of the bay window, which intersect with the lower drip trough 1 of the bay window;

[0051] The laminated wall panel is composed of an inner prefabricated...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com