Cathode-anode synchronous frequency-vibration strong-magnetic auxiliary electro-deposition processing device and method

A deposition device and processing method technology, applied in the field of electrochemical deposition processing, can solve problems such as difficult continuous deposition of high-performance coatings, and achieve the effects of suppressing uneven distribution, high performance, and suppressing grain growth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1)

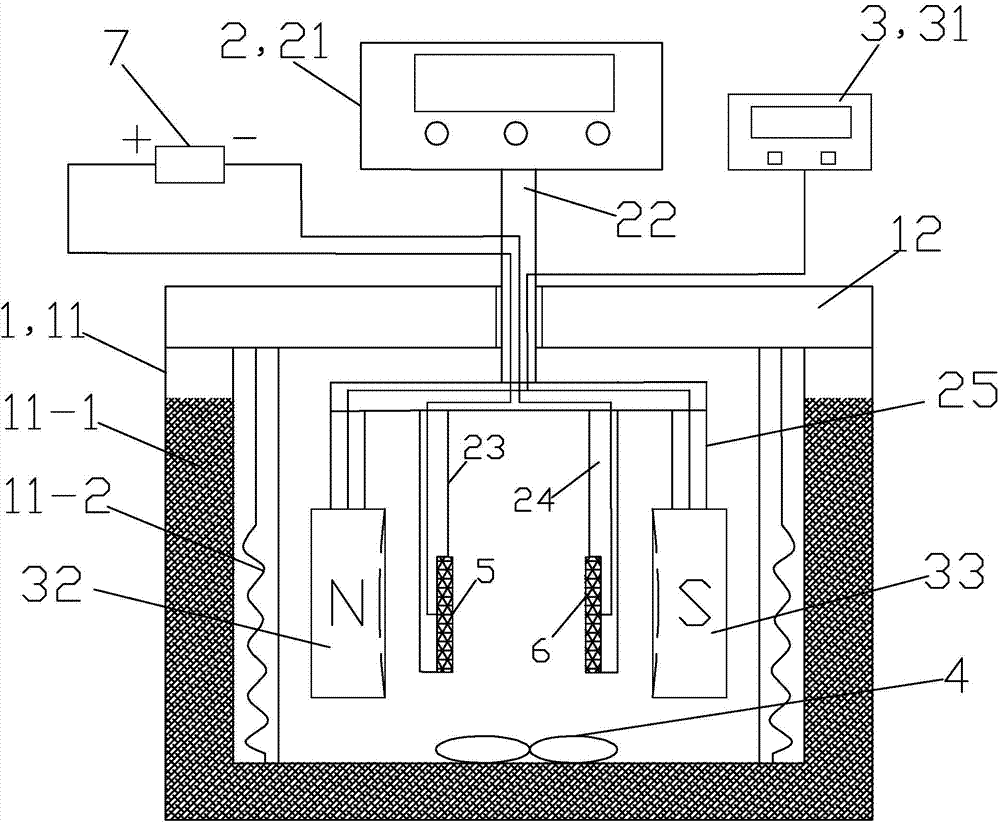

[0034] See figure 1 , the cathode and anode synchronous frequency vibration type strong magnetic assisted electrodeposition device of this embodiment is mainly composed of a reactor 1, a vibration assembly 2, a magnetic control assembly 3, a mechanical stirrer 4, an anode substrate 5, a cathode substrate 6 and a DC power supply 7 .

[0035] The reaction kettle 1 is mainly composed of a main body 11 and a top cover 12 . The main body 11 is provided with an insulating layer 11-1 and a heating coil 11-2 for heating. The middle of the top cover 12 is provided with a through hole penetrating from top to bottom.

[0036] The vibration assembly 2 is mainly composed of a vibration controller 21 , a vibration rod 22 , an anode hanger 23 , a cathode hanger 24 and a magnet hanger 25 . The upper end of the vibrating rod 22 is connected with the vibration controller 21; the lower end of the vibrating rod 22 passes through the through hole of the top cover 12 of the reactor 1 and protrud...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com