Energy-efficient rotary peeling device for sugarcane leaves

A high-efficiency, energy-saving, sugarcane leaf technology, applied in agricultural machinery and implements, applications, harvesters, etc., can solve the problems of poor comprehensive benefit, high labor intensity, technical lag, etc., achieve low manufacturing cost, improve production efficiency, comprehensive Significant economic and social benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

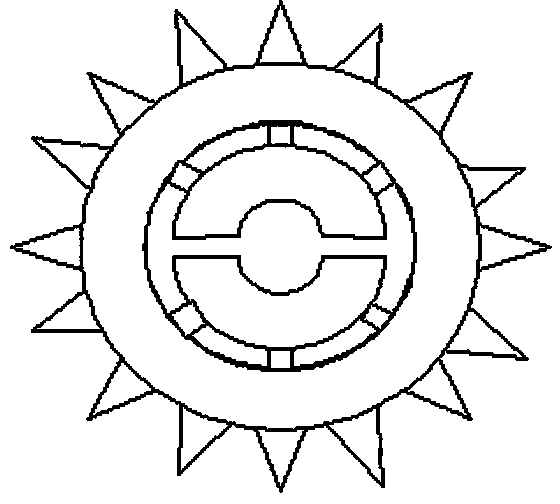

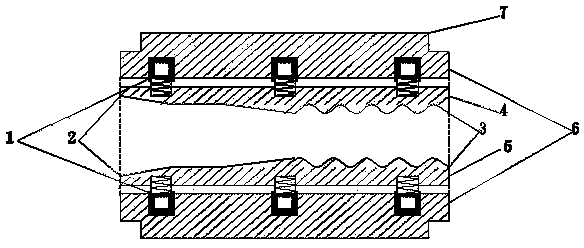

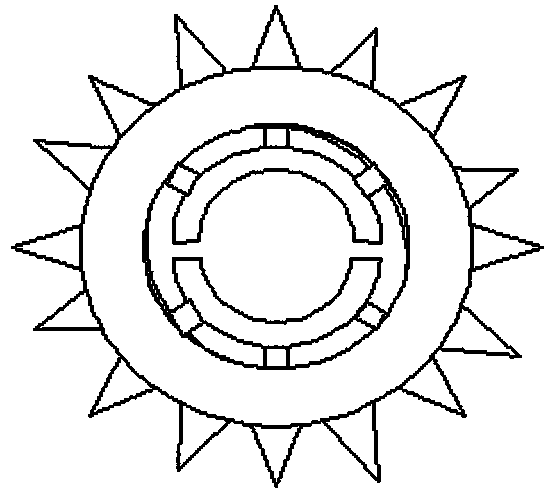

[0024] The outer drive gear 7 of the present invention is configured with the external main drive gear, the outer drive gear 7 drives the outer drive wheel 6 to rotate, and then the outer drive wheel 6 drives the upper stripping roller 4 and the lower stripping roller 5 to rotate through the telescopic rod 1, and the upper stripping roller 5 rotates. The stripping roller 4 and the lower stripping roller 5 synchronously drive the leaf stripping knife 2 and the pulling port 3 to rotate and successively peel off the outer wrapping leaves of the incoming sugarcane stalks. During the working process, the leaf stripping knife 2 and the pulling mouth 3 automatically divide and cooperate, and the leaf stripping knife 2 will pass through the hydraulic pressure or spring in the telescopic rod 1 according to the outer diameter of the cane stalk to be exploited during the synchronous work. The expansion and contraction changes are performed to ensure that the outer wrappers of the cane sta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com