A copper-based graphene stage mechanical adjustment system for carrying fluorescent samples

A mechanical adjustment, graphene technology, applied in control/regulation systems, fluorescence/phosphorescence, non-electric variable control, etc., can solve the problems of unable to excite fluorescent samples, achieve high resolution, ultra-high resolution, easy disassembly and The effect of installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

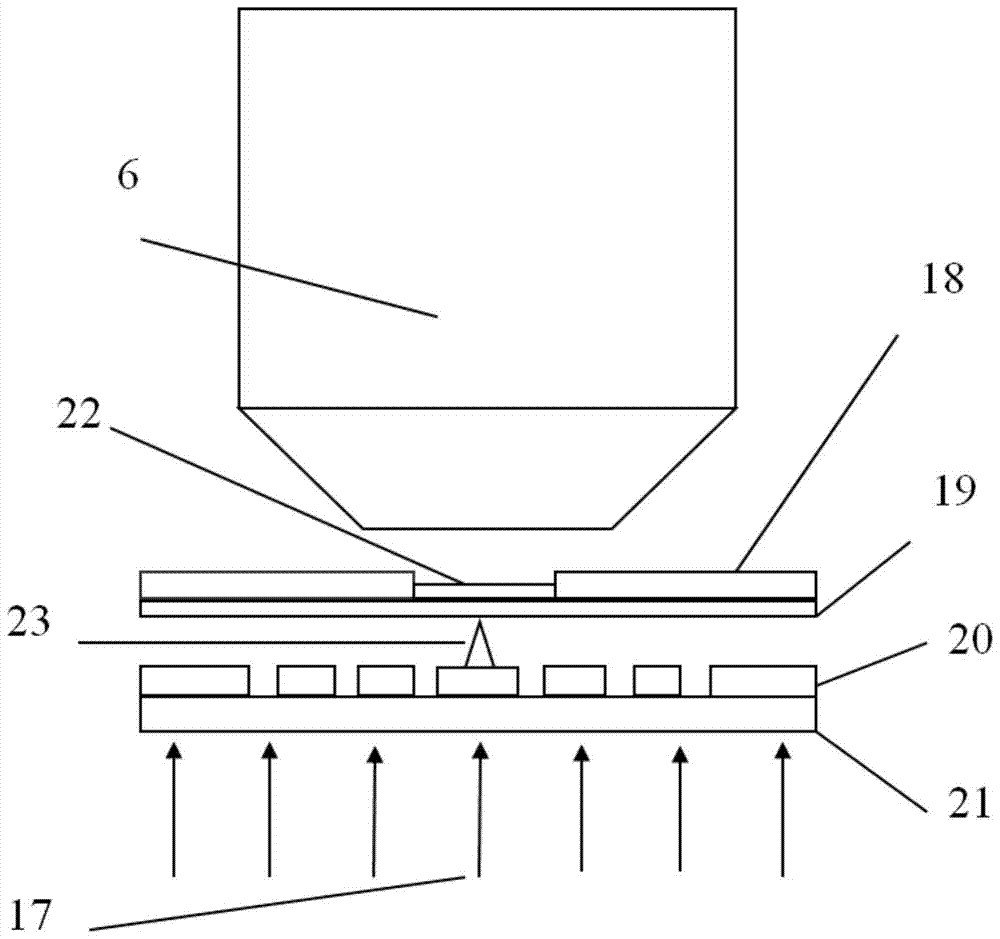

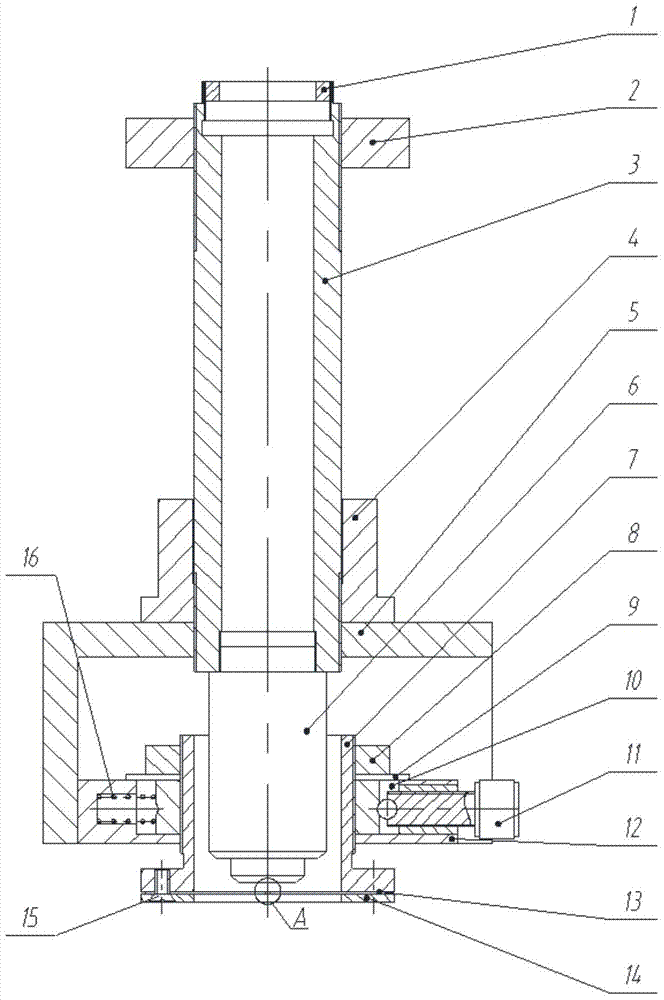

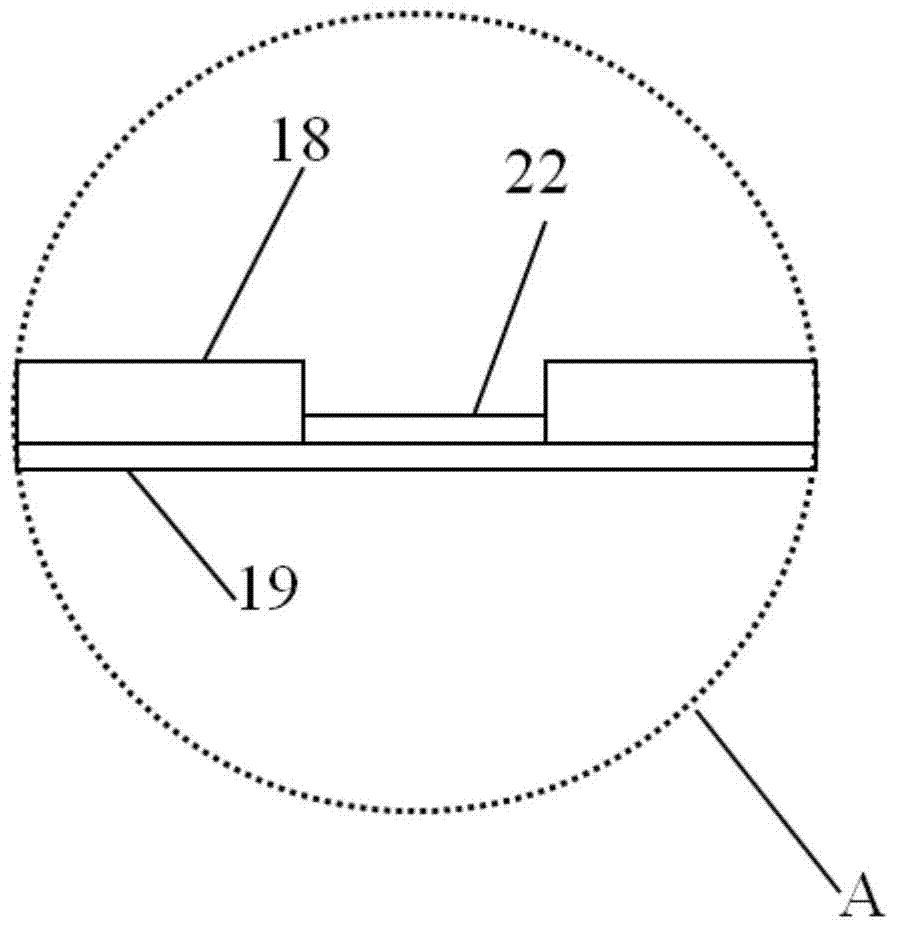

[0039] The copper-based graphene stage mechanical adjustment system for carrying fluorescent samples according to the present invention includes a main lens barrel 3, a support frame 5, a fluorescence detection objective lens 6, a cylindrical barrel 7, a movable block 10, a screw I11, a two-dimensional Manual adjustment frame 12, copper-based suspended graphene 13 carrying fluorescent samples, and spring 16.

[0040] The fixed block 2 is located on the outer wall of the top of the main lens barrel 3, and has a length and width of 69 millimeters and a thickness of 10 millimeters. When in use, the main lens barrel 3 is connected to the P-733.3cd three-dimensional nano-displacement stage of PI Company through the fixed block 2. The length of the main lens barrel 3 is 120 mm, the outer diameter of the main body is 32 mm, and the inner diameter is 20 mm. The inner wall of the upper end is threaded, and its diameter matches the optical filter and the focusing lens of 25.4 mm. The op...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com