Device and method for comprehensively detecting friction between steel wire ropes and friction liners of hoist

A friction pad, friction detection technology, applied in measuring devices, mechanical devices, instruments, etc., can solve problems such as inability to achieve

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0056] The present invention will be described in detail below in conjunction with specific embodiments.

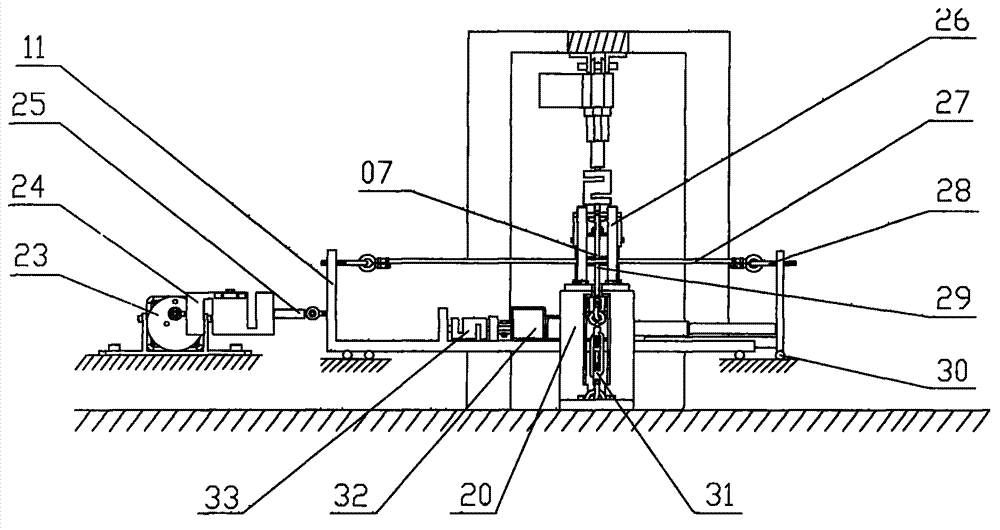

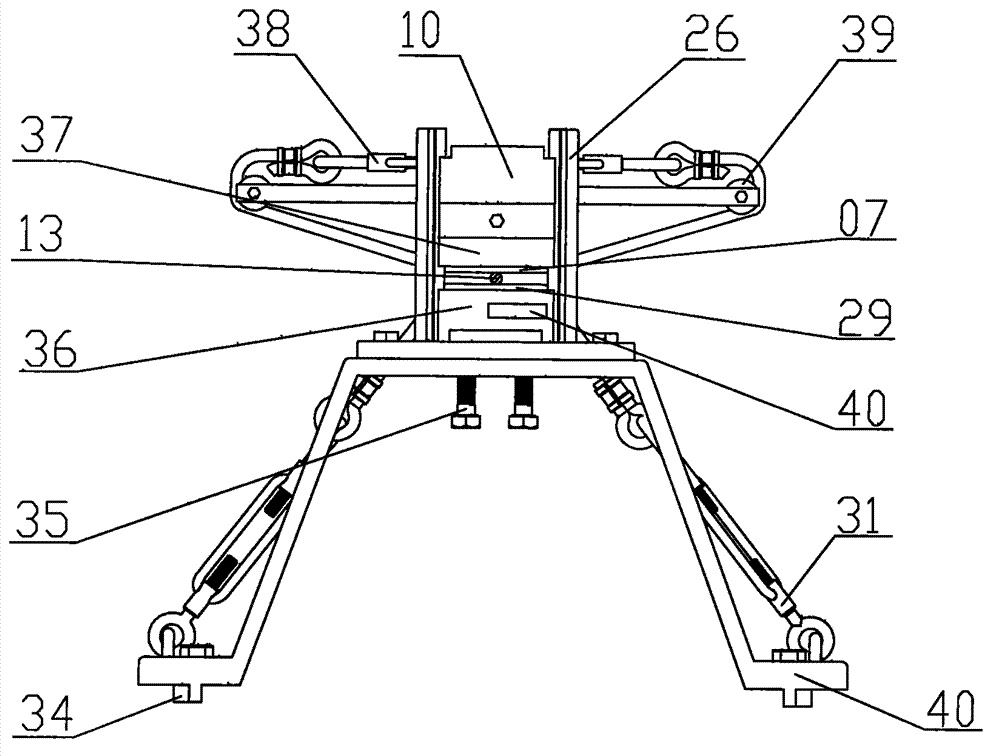

[0057] Such as Figure 1-6 As shown, a steel wire rope and friction lining comprehensive friction detection device for a hoist is used to simulate the cross contact continuous high-speed sliding friction between steel wire rope and steel wire rope Pad continuous high-speed sliding friction working conditions, and detect the relevant friction and wear parameters under each working condition. The device includes a base frame, a steel wire rope placed on the Continuous creeping friction and wear system and steel wire rope and friction lining continuous high-speed sliding friction system.

[0058] The power source drives the active friction wheel 04 to rotate to drive the jointless steel wire rope 13 to move at high speed. At this time, the test device can simulate the continuous high-speed sliding friction between the steel wire rope and the cross contact between the steel ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com