A New Type of Adjustable Phase Coupling

A coupling and phase technology, applied in the direction of couplings, elastic couplings, mechanical equipment, etc., can solve the problems of increased labor intensity, unsatisfactory, time-consuming, etc., to shorten downtime, reduce labor intensity, and improve products quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

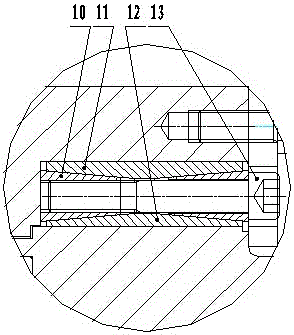

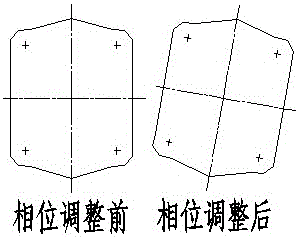

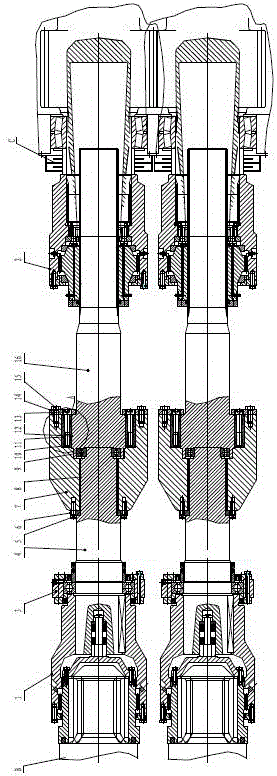

[0014] From figure 1 , figure 2 It can be seen that the present invention is a new type of adjustable phase coupling, which includes a roller end assembly 1, a tooth end assembly 2, a support frame assembly 3, and it also includes a first spline shaft 4, a second spline shaft 16, and Phase adjustment assembly; the left end of the first spline shaft 4 is sleeved with the roller end assembly 1 and the support assembly 3, the right end of the second spline shaft 16 is sleeved with the tooth end assembly 2, the right section of the first spline shaft and the second The left section of the spline shaft 16 is connected by an adjustable phase assembly.

[0015] Among them, the adjustable phase assembly includes a snap ring 6, a connecting sleeve 7, a pressure plate 14, and a transmission component; the first spline shaft 4 is connected with the inner spline of the connecting sleeve 7 through the outer spline at the right end to form a spline pair 8; The ring 6 is sleeved on the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com