Spinning machine and table holder

A spinning machine and receiving part technology, applied to spinning machines, textiles, papermaking, drafting equipment, etc., can solve the problems of large workload, spinning machine consumption, wrong setting, etc., and achieve fast and simple setting , to achieve the effect of stable placement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

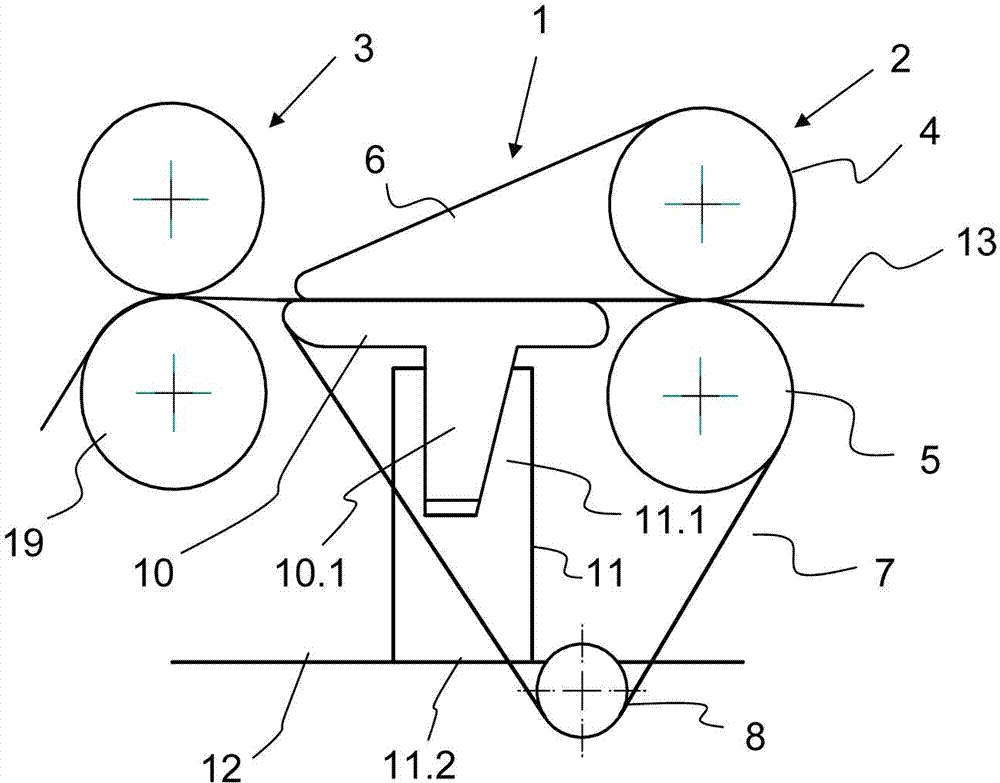

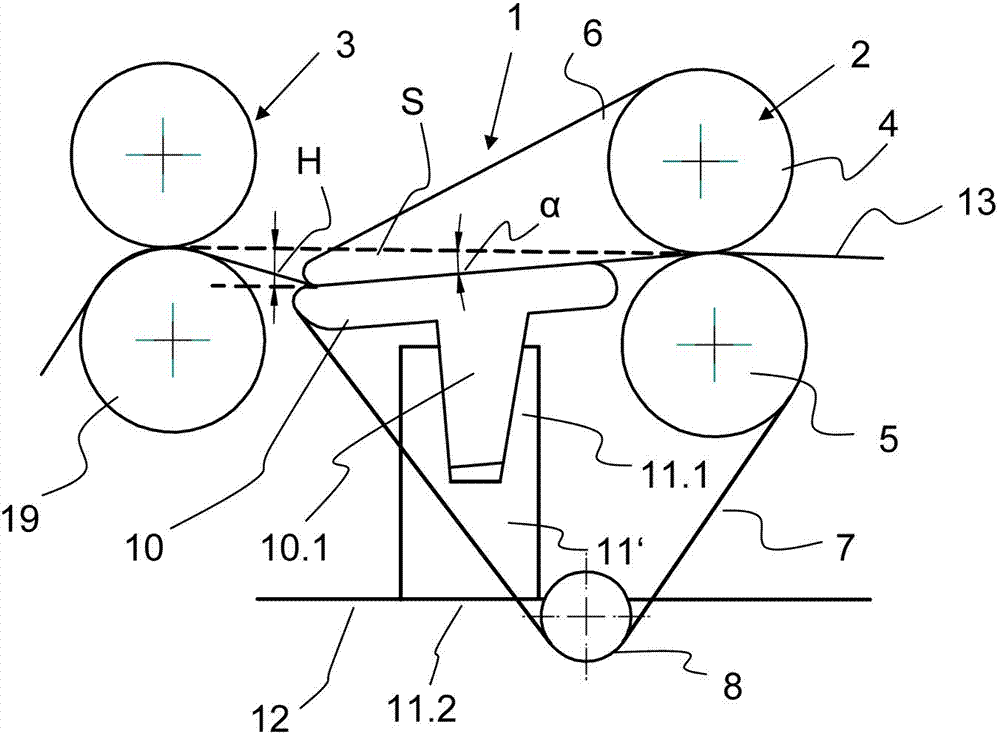

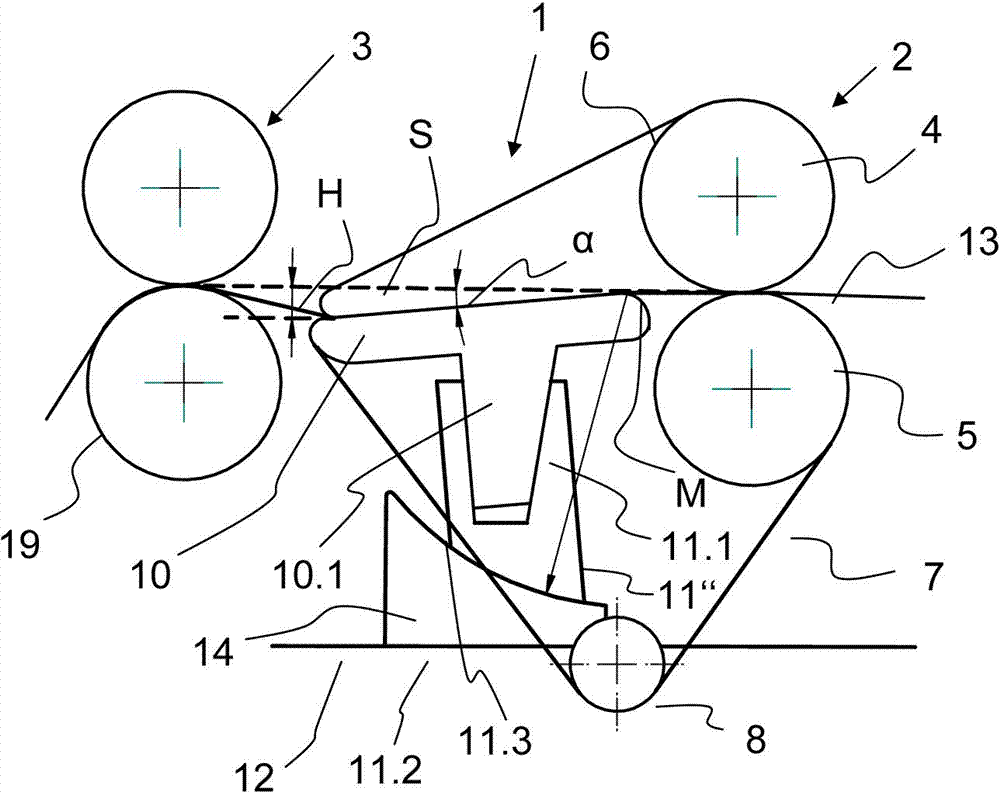

[0029] figure 1 A side view of a section of the drafting device is shown diagrammatically. Only the guide 1 with the double belt 2 and one delivery roller pair 3 is shown in this figure. The input roller pair and the oscillating support for fixing the upper roller of the drafting device are not shown here. The guiding device 1 has an upper band roll 4 and a lower band roll 5 . On the upper band roll 4 is mounted an upper band 6 which is deflected on deflection means (not shown). The lower band roll 5 is partially wound by the lower band 7 . The lower band 7 is guided by reversing rolls 8 . In addition, the lower strap 7 is wound around a guide table 10 mounted on a guide table receiver 11 . The guide table receptacle 11 is attached to the punch 12 via a contact surface 11.2.

[0030] In this design, the upper side of the guide table 10 moves in the drafting area plane, through which the spun yarn 13 is guided by the drafting device. In this design the guide table 10 is no...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com