Automatic wallboard demolding, stacking and separating equipment

A technology of automatic demoulding and separating equipment, applied in auxiliary molding equipment, object stacking, unloading devices, etc., can solve the problems of low labor efficiency and high labor intensity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The embodiments of the present invention will be described in detail below in conjunction with the drawings and examples, so as to fully understand the present invention.

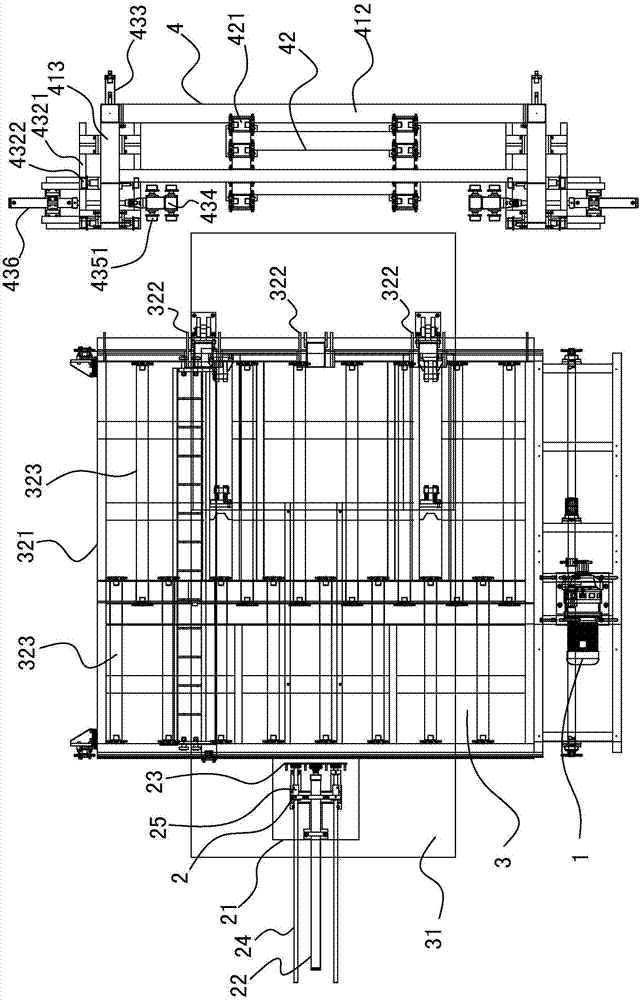

[0023] A wall panel automatic demoulding, stacking and separation equipment of the present invention is arranged in the vertical vertical formwork wall panel production line after being connected to the maintenance line, specifically after the wall panel forming machine is output from the maintenance, the wall panel forming machine is formed The machine overturning car performs 90 overturns on the side where its open end is facing, and the automatic action of the whole machine is controlled by the control system. The structure of the whole machine is described in detail below.

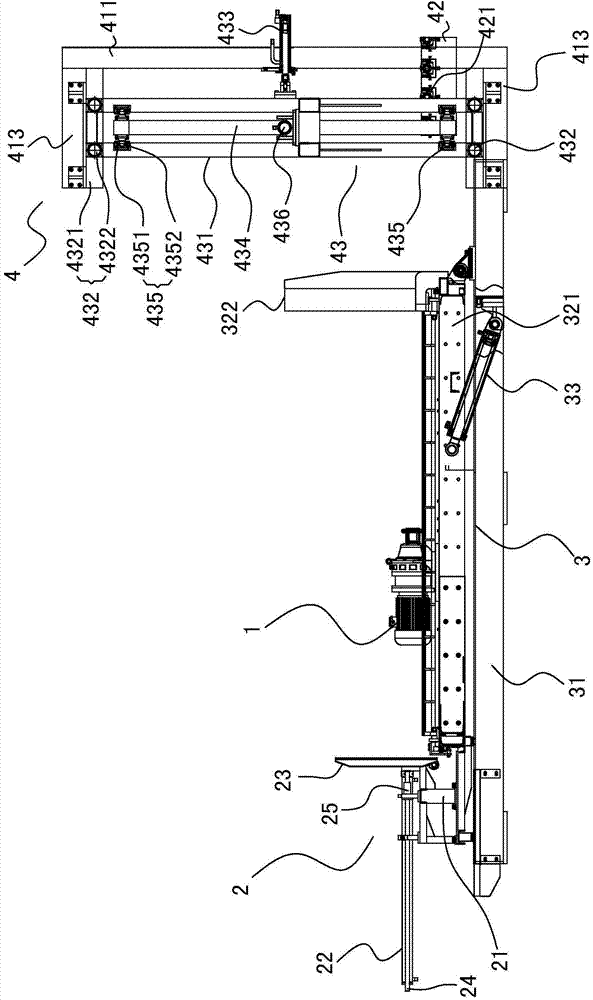

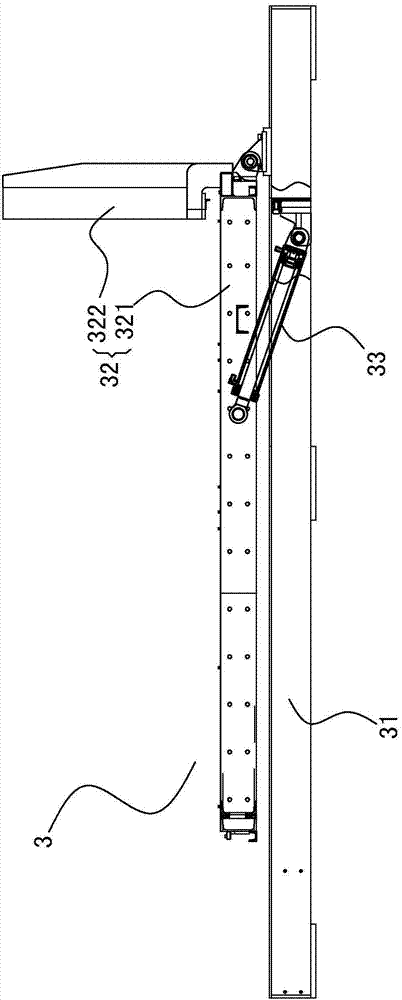

[0024] A wall panel automatic demoulding, stacking, separation equipment, such as figure 1 , figure 2 and Figure 8 As shown, it includes a demoulding device 1 for automatically pulling out the formed wallboard 100 from t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com