Spool drive

A driving device and valve core technology, which is applied in fluid circulation arrangement, refrigeration safety arrangement, refrigeration components, etc., can solve the problems of weak shell strength, inability to locate the shell, strong elastic sheet, etc., and achieve the effect of accurate positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

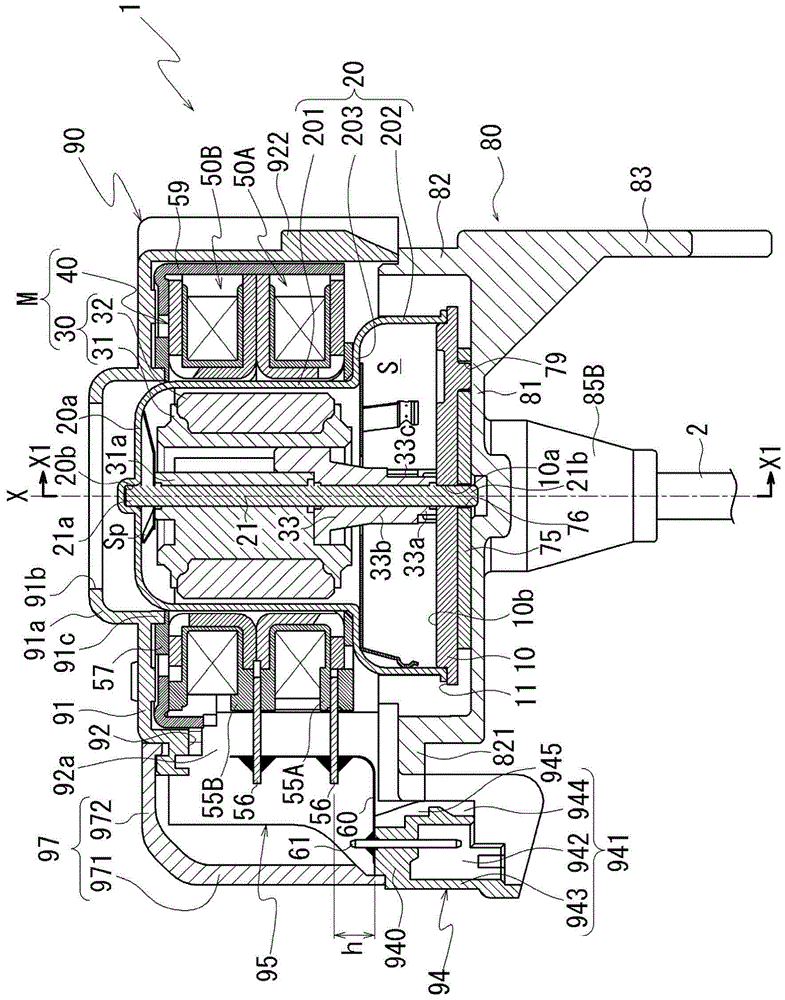

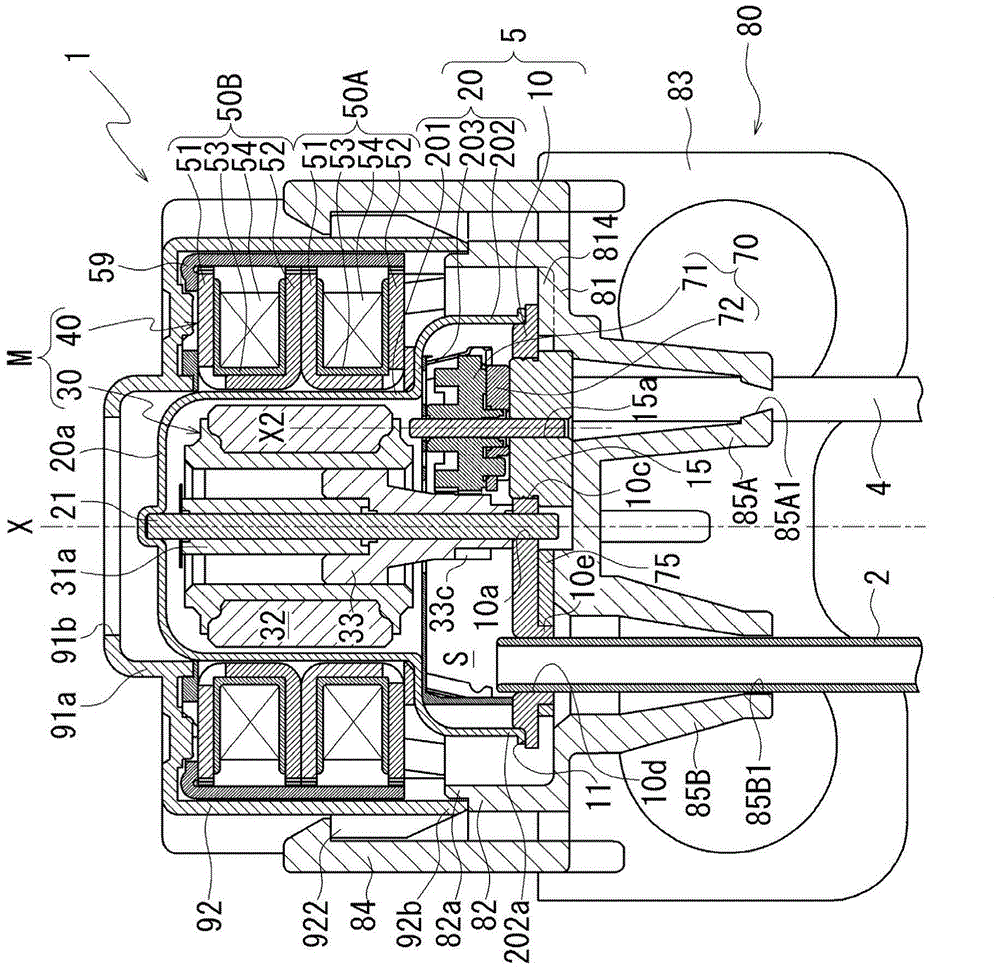

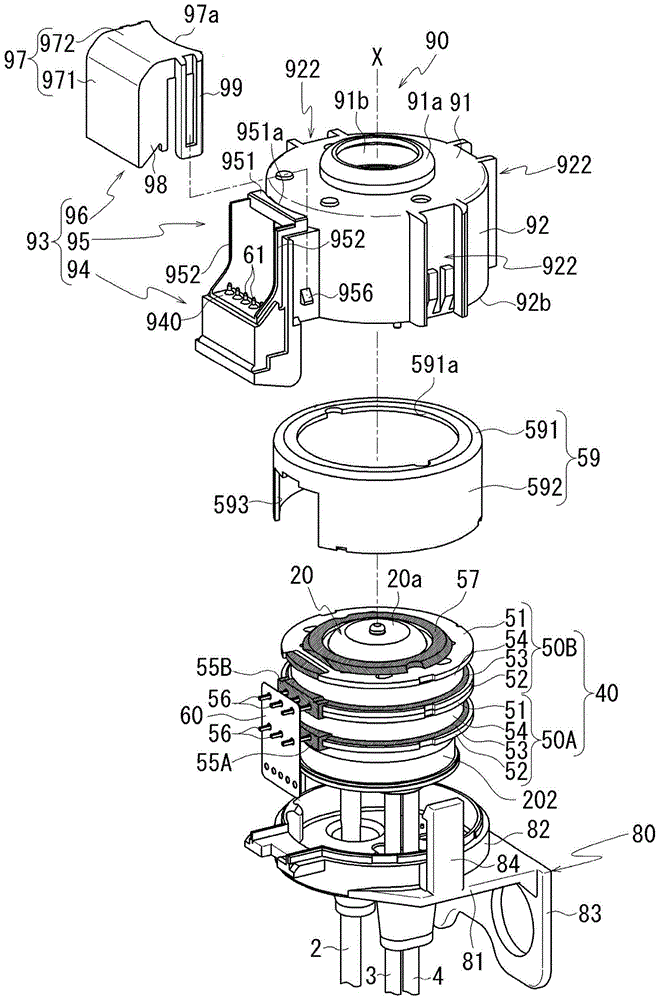

[0021] Hereinafter, embodiments of the present invention will be described in detail by taking the case where the present invention is applied to a valve element driving device (gear unit) of a valve device that opens and closes a refrigerant flow path of a refrigerator as an example, with reference to the drawings as appropriate. In addition, in each figure, the same code|symbol is attached|subjected to the common part, and overlapping description is abbreviate|omitted. In the following instructions, start with figure 1 The axis X of the rotating shaft of the rotor 30 of the shown spool driving device 1 is taken as a reference, and the rotor 30 side in the axial direction of the axis X is set as the upper side, and the fluid outlet pipes 3 and 4 sides are set as the lower side, and the valve is appropriately described. The positional relationship of each component of the core drive unit.

[0022] figure 1 It is a cross-sectional view of the valve body driving device 1 accor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com