Fabricated building block, fabricated building block wall and construction method of wall

A prefabricated and block-based technology, applied to walls, building components, buildings, etc., can solve the problems of labor and materials, occupation of cultivated land, waste of materials, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The present invention will be further described in detail below in conjunction with the accompanying drawings and examples. The following examples are explanations of the present invention and the present invention is not limited to the following examples.

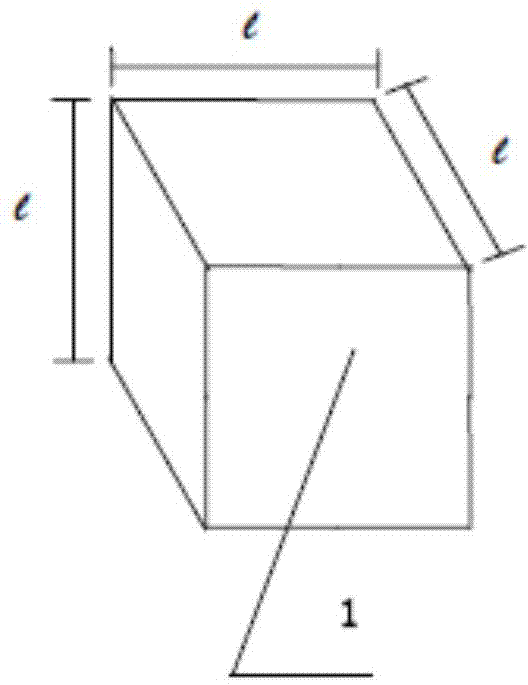

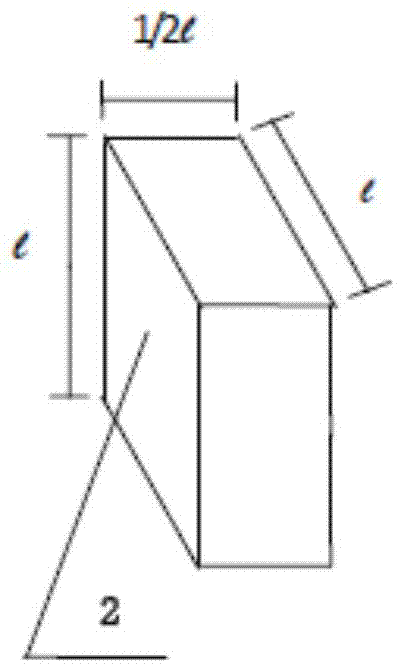

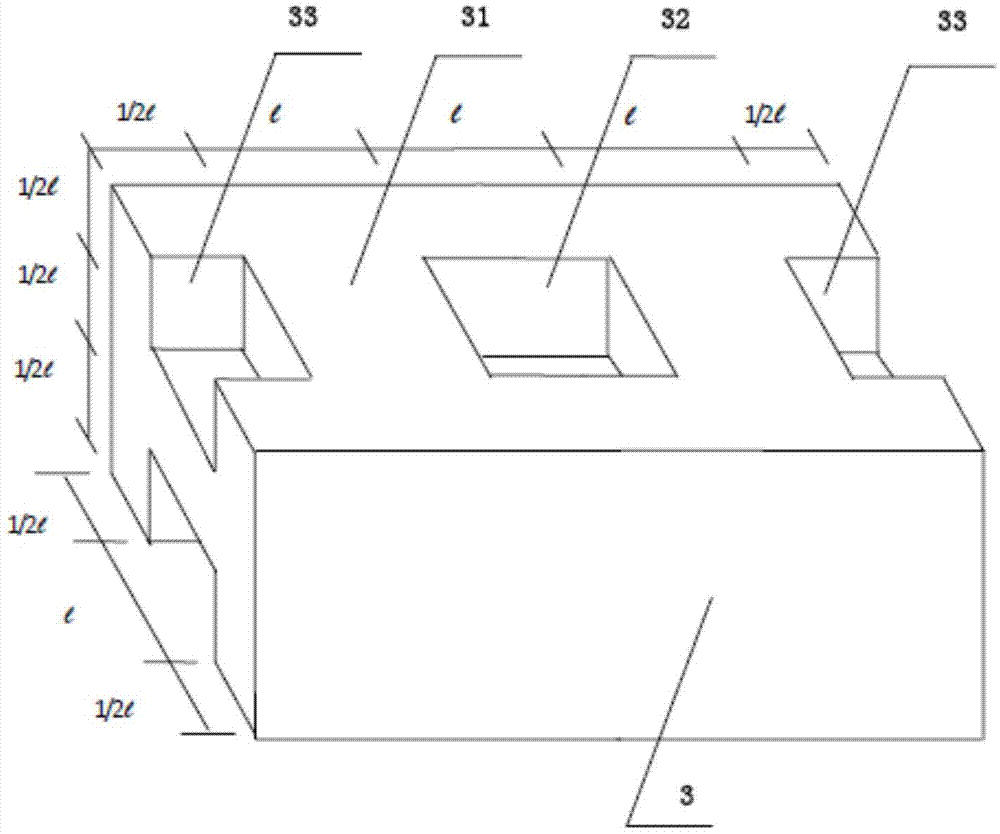

[0046] Examples see Figure 3-12. This prefabricated block is composed of a main block 3 and an auxiliary block. The main block 3 is composed of a block entity 31, 1 / 2 pin hole 32 and 1 / 4 pin hole 33. The auxiliary block includes 1 / 2 2 main block 4, cross node block 5; T-shaped node block 6; 1 / 2 T-shaped node block 7; end block 8; 1 / 2 end block 9; corner block 10; 1 / 2 corner block Block 11; foundation block 12; 1 / 2 foundation block 13; cover plate 14; 1 / 2 cover plate 15. These prefabricated blocks and cubic pin blocks are combined to form a wall, the blocks are composed of pin pits and block entities, and the prefabricated block wall is composed of blocks and cubic pin blocks.

[0047] The main building block 3 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com