Wall drilling dust collector

A technology for dust collectors and walls, applied in the field of wall drilling dust collectors, can solve problems such as difficulty in cleaning, indoor environmental pollution, and impact on operational flexibility, and achieve the effects of avoiding direct friction and wear, improving flexibility, and being easy to manufacture.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

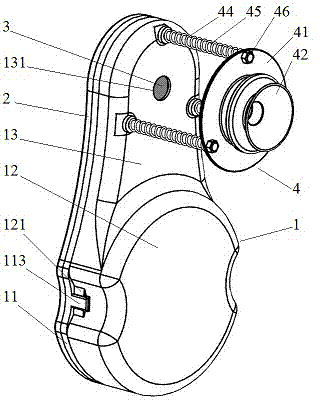

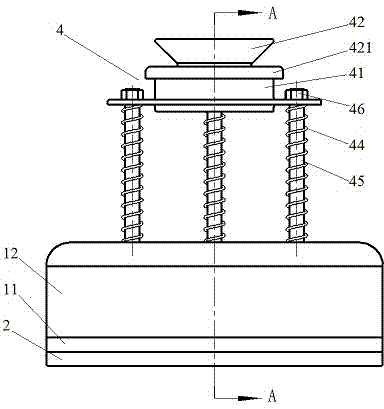

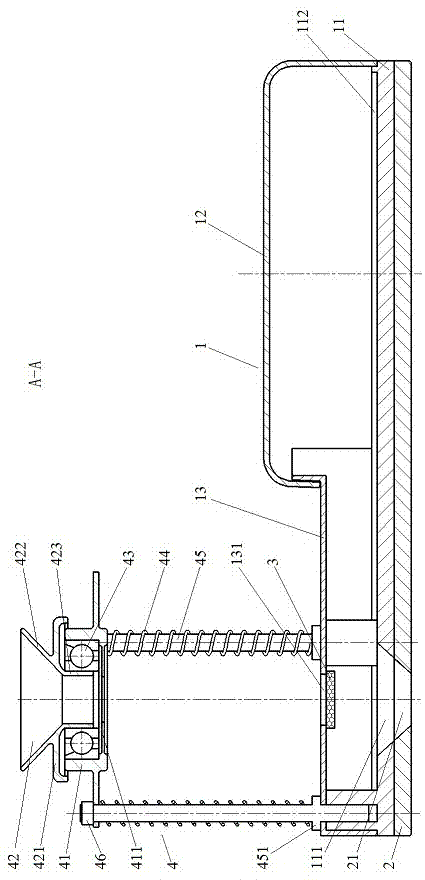

[0019] like figure 1 , 2 As shown in and 3, the present invention relates to a wall drilling dust collector, which includes a dust collection body 1, a soft rubber pad 2, a dust screen 3 and a drill guide 4; the dust collection body 1 includes a box body 11, and Dust box 12, front box cover 13; said drill guide 4 includes a flange 41, a guide seat 42, a bearing 43, a spring 44, a guide post 45, and a nut 46. The dust screen 3 is bonded to the inner wall of the through hole 131 on the front cover 13 with an adhesive, and the soft rubber pad 2 and the box body 11 are bonded. The drill guiding device 4 is threadedly mounted on the dust collecting body 1 through the guide post boss 451 and the end of the guide post 45 , and is threadedly connected to the front box cover 13 and the box body 11 . The soft rubber pad 2 , the box body 11 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com