Automotive natural gas tank fixing support

A technology for fixing brackets and natural gas, which is applied to vehicle components, the layout combined with the fuel supply of internal combustion engines, power units, etc. Fixed effect, conducive to placement and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The implementation of the present invention will be illustrated by specific specific examples below, and those skilled in the art can easily understand other advantages and effects of the present invention from the contents disclosed in this specification.

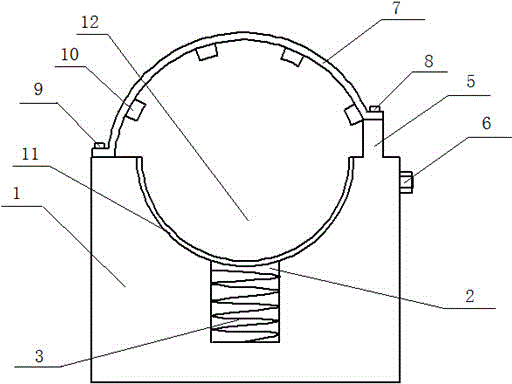

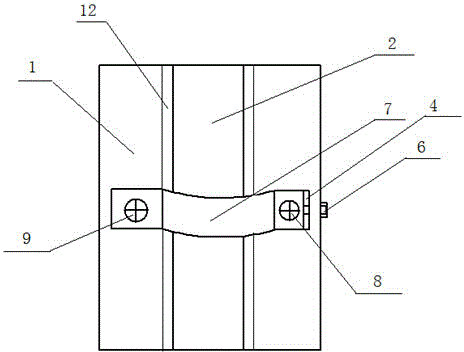

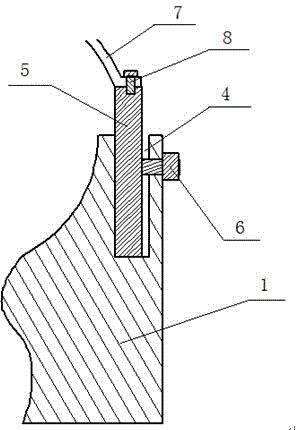

[0022] Such as figure 1 As shown, a natural gas tank fixing bracket for a vehicle includes a rectangular base 1 with a U-shaped groove 12 and a fixing buckle fixedly connected to the base 1 above the base 1 . Such as figure 2 As shown, a groove 2 is formed horizontally at the bottom of the U-shaped groove 12 of the base 1, and a shock absorbing device 3 is fixedly installed in the groove 2. Such as image 3 As shown, the right end of the U-shaped groove 12 of the base 1 has a square column hole 4 along the vertical direction, and a square column 5 is inserted in the column 4 holes. combine figure 1 and figure 2 As shown, the fixing buckle structure is a flat arc-shaped hoop 7, one end of the hoop 7 is fixedly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com