The method of welding the tailgate of the car body

A technology of tailgate and car body, applied in welding equipment, welding equipment, auxiliary welding equipment, etc., can solve the problems of high cost, inconvenient operation, difficult cylinder turning over, etc., and achieve the effect of safe and convenient welding and high work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in further detail below in conjunction with accompanying drawing embodiment:

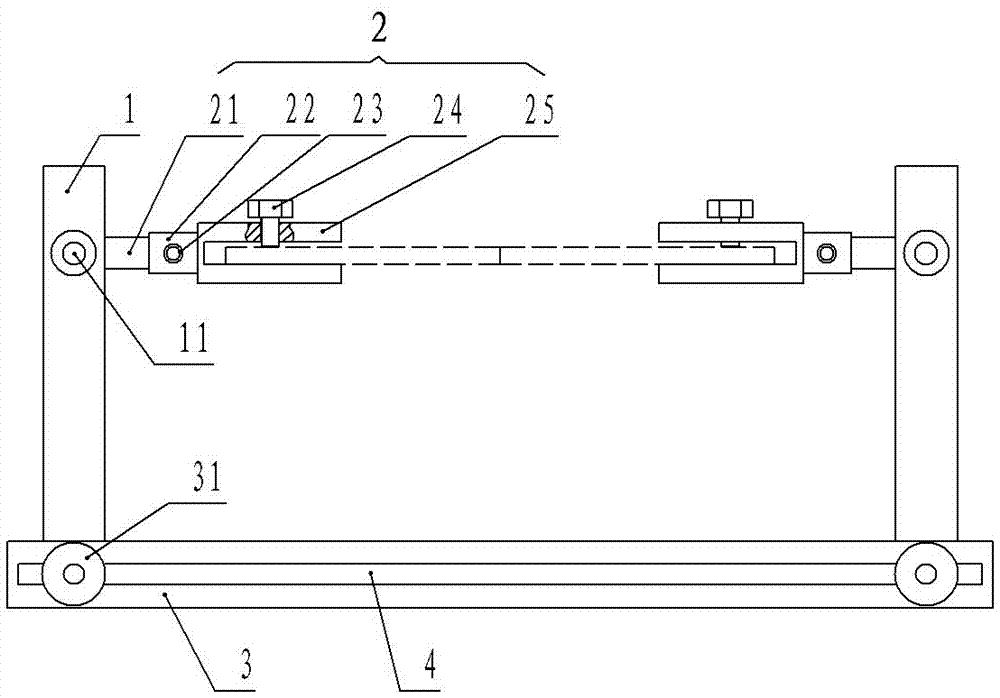

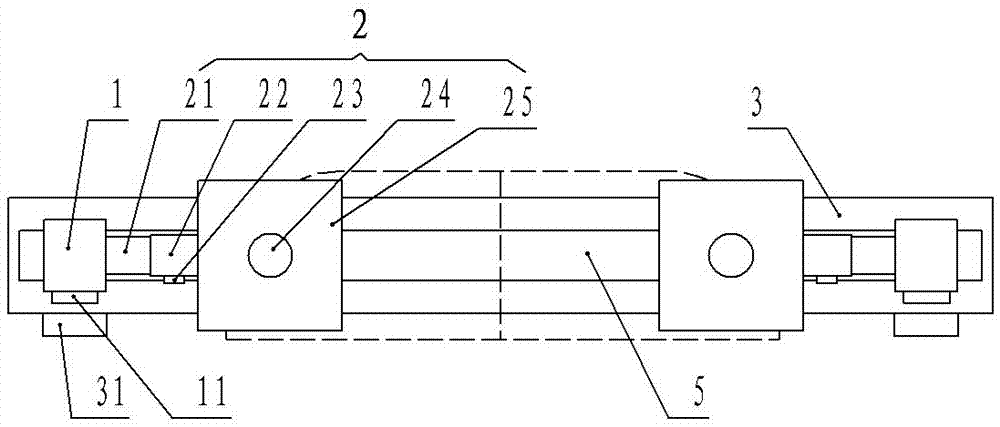

[0019] The method of welding the tailgate of the car body adopts a method such as figure 1 , figure 2 The welding tool for the rear fender of the car body shown in the figure includes a base 3 on which two supporting rods 1 stand opposite to each other, and the upper end surface of the base 3 is provided with chute 5 and 2 in the same length direction as the base 3 The lower ends of the support rods 1 all have sliders, and the sliders are all worn in the chute 5 and are slidably connected with the base 3; And the movable sleeve 22 that is set on the slide bar 21 and fixedly connected with the chuck 25 through the movable sleeve locking screw 23, the chuck 25 is equipped with the workpiece compression screw 24, and the support rod 1 is provided with a lock through the workpiece clamp. A chute for sliding connection of the screw 11 and the workpiece ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com