Foundation pit anti-floating anchor rod pull-out test tool

A technology of anti-floating anchor rod and pull-out test, applied in the test of basic structure, basic structure engineering, construction, etc., can solve the problems of wasting time, labor and materials, affecting efficiency, etc., to reduce costs and achieve simple and easy operation. performance, improve work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

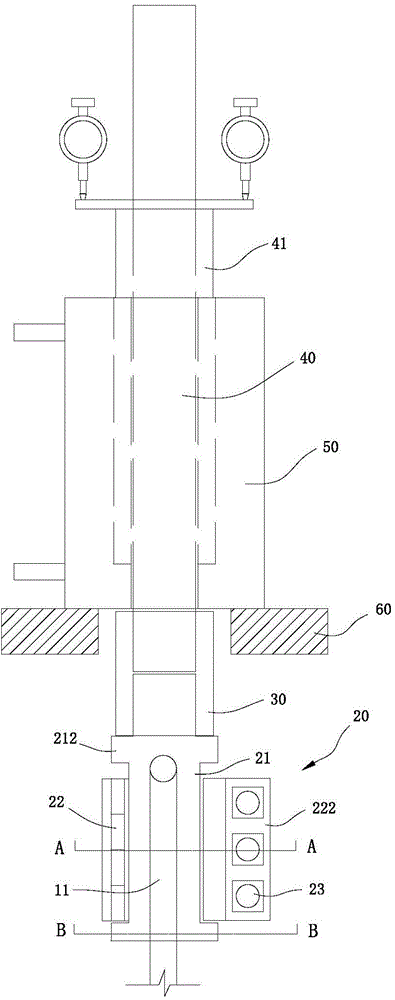

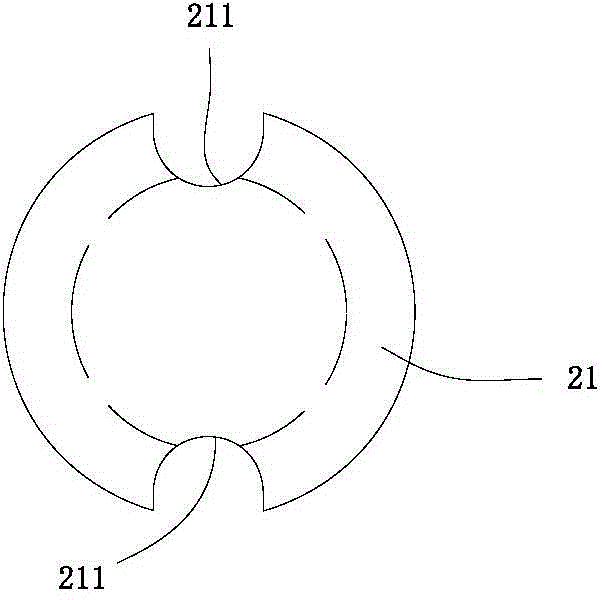

[0023] refer to Figure 1 to Figure 5 , a foundation pit anti-floating anchor pull-out test tool, including an anchor bar composed of several anchor tendons 11, an anchor bar locking assembly 20 composed of a locking bar 21 and a locking member, a connecting sleeve 30, and an extended anchor bar 40 And the through-core jack 50, the upper end of each anchor bar 11 in the anchor bar is bent symmetrically from the center outward to form a bending part 12, and the outer wall of the lower part of the lock bar 21 is vertically provided with a plurality of slots for the anchor bars 11 to be embedded and placed at symmetrical intervals 211, the locking member is fastened on the lower part of the locking bar 21 to lock the anchor bar 11 in the channel 211, the middle part of the locking bar 21 has a step structure 22 that resists the bending part 12 of the anchor bar 11, and the upper end of the locking bar 21 is connected to the The lower ends of the extended anchor rods 40 are connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com