Flywheel mold stripper

A technology of a feeder and a flywheel, which is applied in the field of feeders, can solve the problems of consuming a lot of manpower and time, inconvenient removal of the flywheel, and damage to castings, etc., and achieves the effect of saving financial resources.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

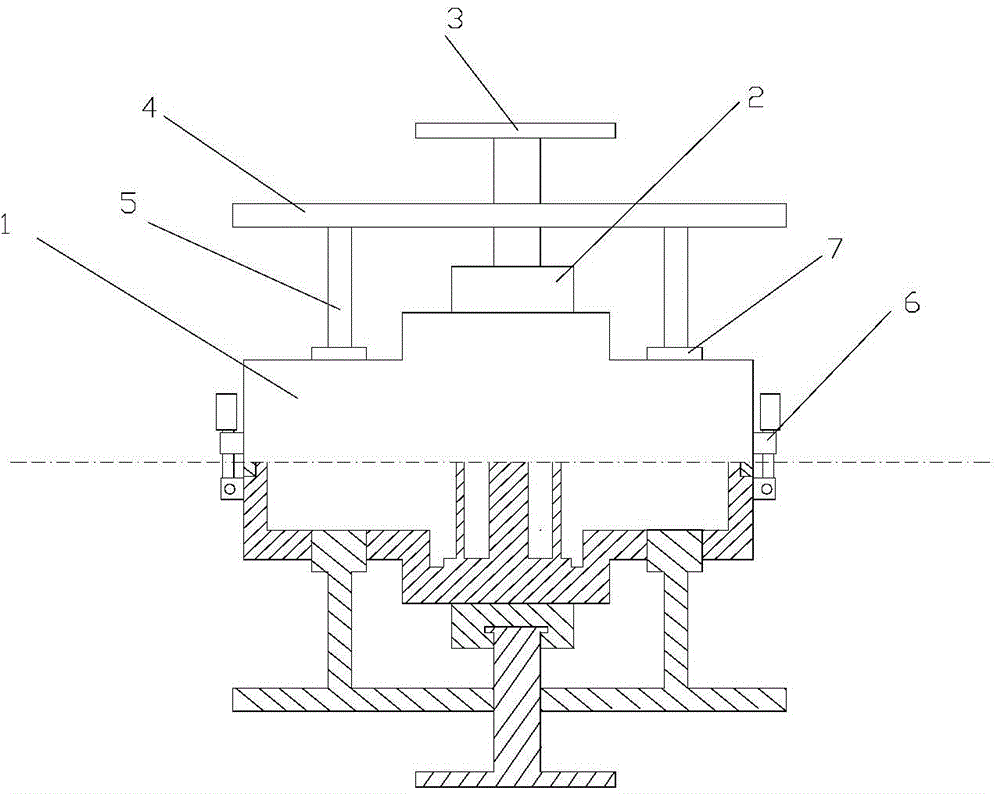

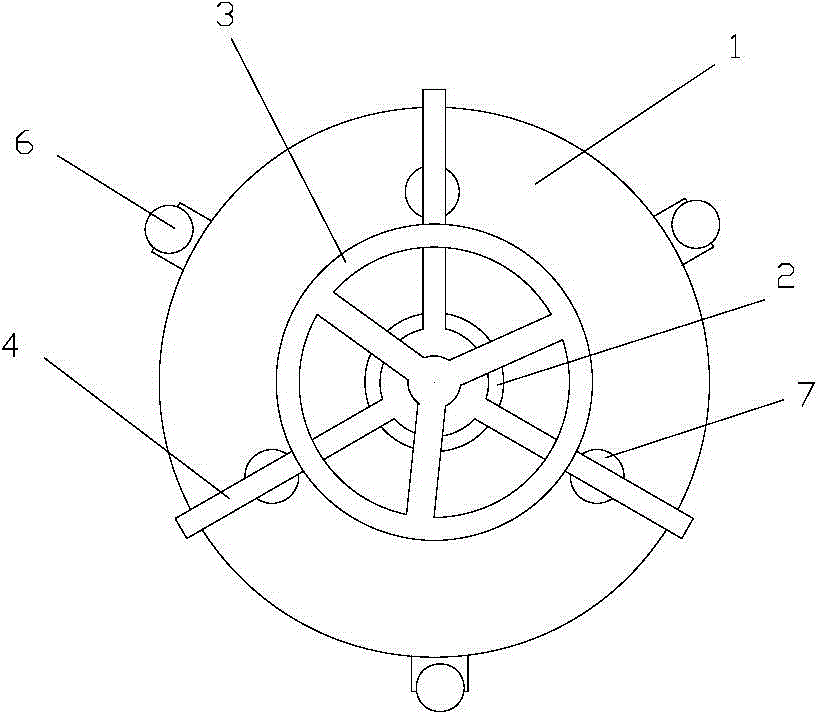

[0013] The figure shows a flywheel mold ejector, including a flywheel mold cover 1 and a material ejector. The flywheel mold cover is divided into an upper mold cover and a lower mold cover. , both the upper mold cover and the lower mold cover are provided with ejection holes, the ejection holes are evenly distributed on the flywheel mold cover in a circular shape, and the upper mold cover and the lower mold cover are equipped with ejectors, which include fixed The connecting block 2, the runner 3, the bracket 4, and the ejector rod 5 are composed of the fixed connecting block fixed at the center position outside the flywheel mold cover, and the runner is movably connected with the fixed connecting block through the fixed rotating rod, and the rotating rod is provided with threads , the runner can rotate freely, and the bracket is set as a horizontal bracket. The bracket is composed of a center piece and a support rod. The number of support rods is 3. The support rods are evenl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com