An automatic alignment multi-station part mounting machine

A technology of automatic alignment and parts installation, which is applied to the equipment of acoustic mesh and rear camera foam to the back shell of mobile phones, and the field of assembling mobile phone appearance mesh, which can solve the problems of difficult positioning, small size of parts, inaccurate positioning, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

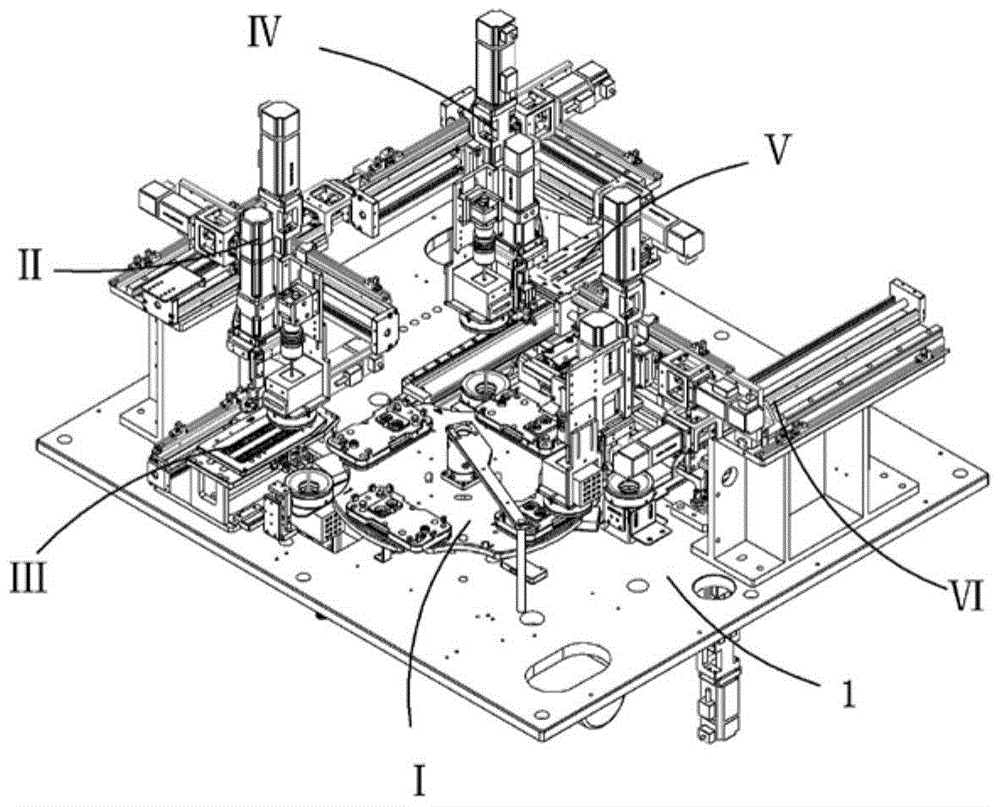

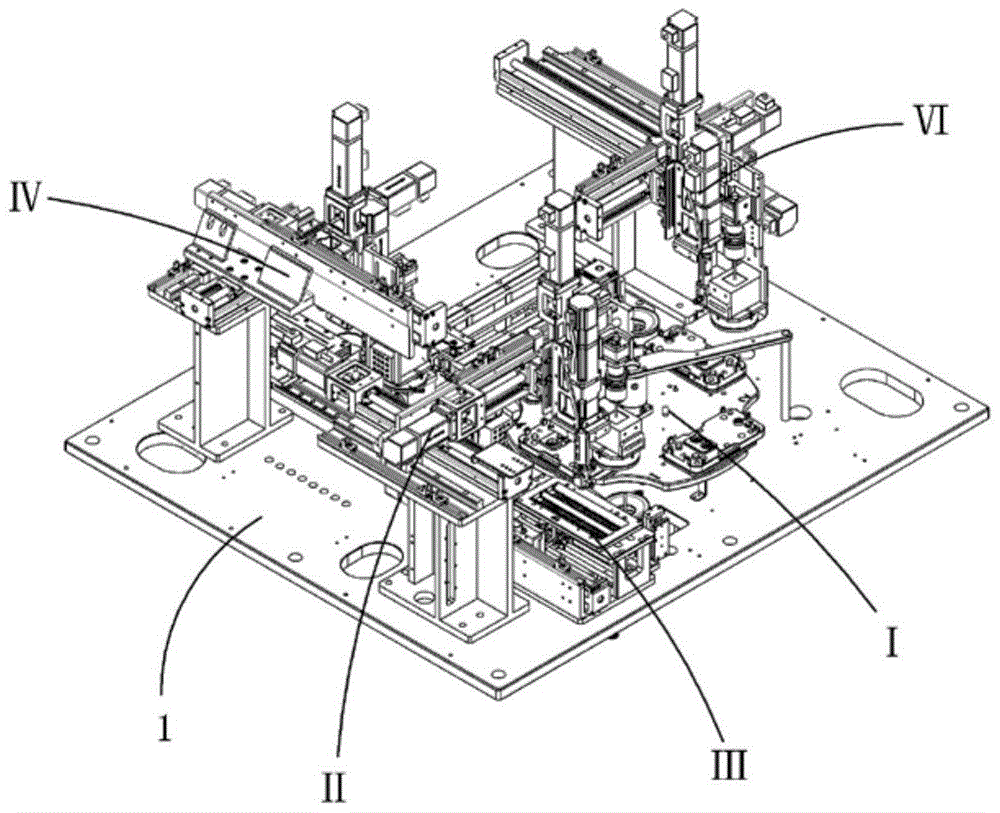

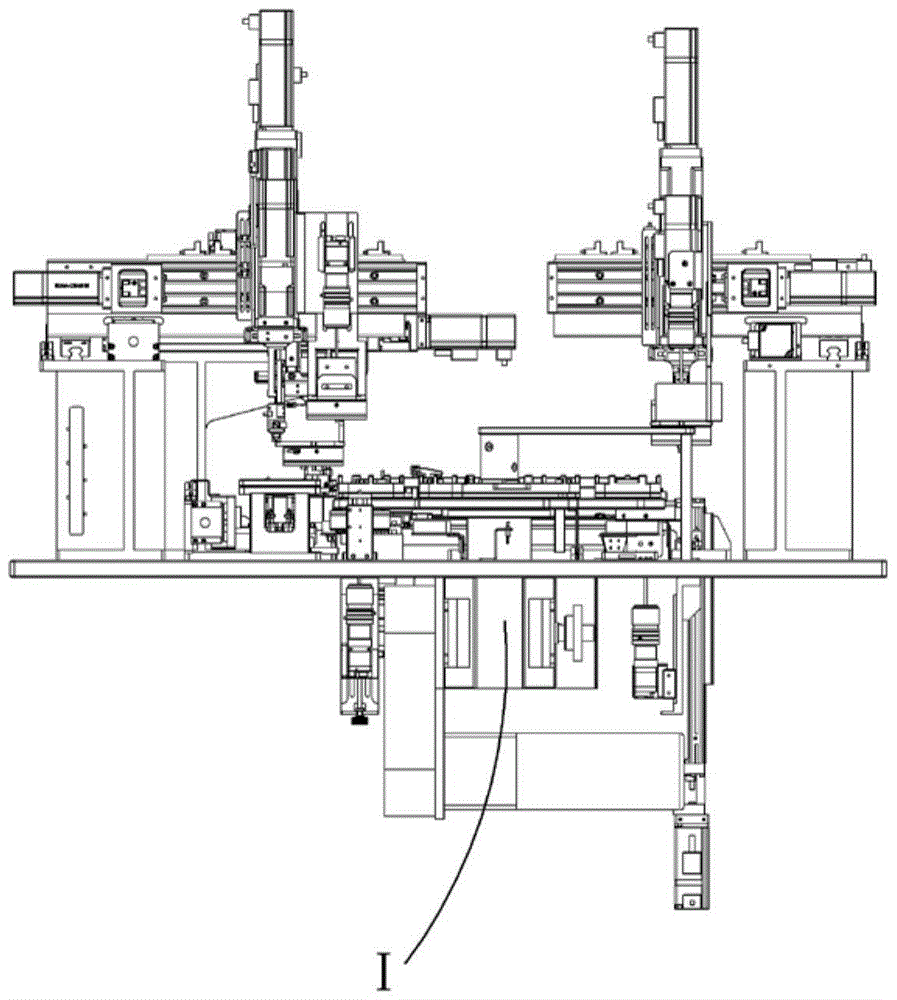

[0050] Examples, see attached Figure 1-32 , an automatic alignment multi-station part mounting machine, which includes a bottom plate 1 and a turntable mechanism I, the turntable mechanism is installed at the center of the bottom plate, and also includes a part installation station II, a one-station stripping mechanism III, parts Install the second station IV, the second station feeding mechanism V, the three parts installation station VI and the three parts stripping mechanism VII, the parts installation first station, the parts installation second station and the parts installation three stations are respectively installed on the bottom plate Left front, left rear and right rear for mounting different parts to electronics.

[0051] The turntable mechanism includes a rotating divider 2, a rotating shaft 3 and a turntable 4. The rotating divider is installed at the bottom of the base plate. The output end of the rotating divider is equipped with a turntable through the rotati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com