Process for instructing filling mining by observing variation of filling sensitive layer

A process method and sensitive layer technology, applied in the direction of filling, ground mining, mining equipment, etc., can solve the problems of blind filling mining, ignoring the lithology of the overlying strata and protection objects, and waste, so as to reduce filling costs and improve Economic benefits of coal mines and the effect of realizing the integration of technology and economy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

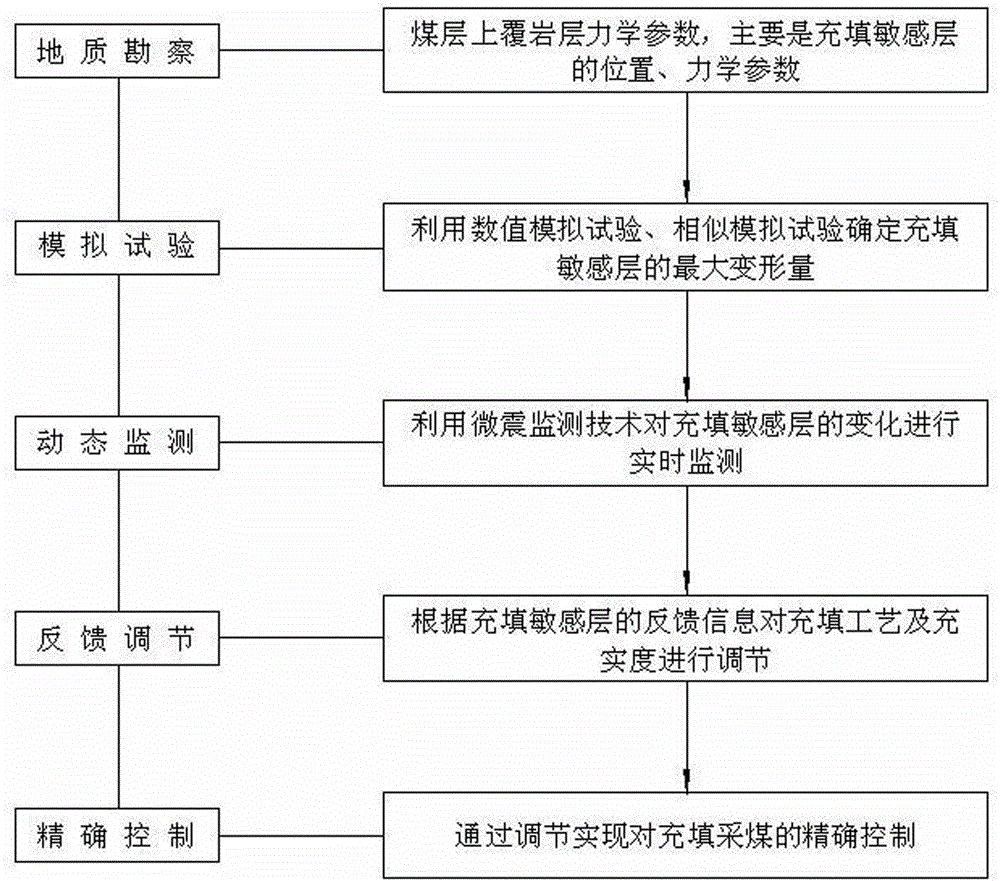

[0016] Such as figure 1 As shown, the specific implementation steps of a technical method for guiding filling mining by observing changes in filling sensitive layers:

[0017] (1) Use drilling and geophysical prospecting methods to carry out fine survey of the geological structure of a certain coal mine, mainly the filling sensitive layer, determine the location of the filling sensitive layer, take core samples from the filling sensitive layer through drilling, and test the samples in the laboratory to further Determine the mechanical parameters of the filling sensitive layer, including bulk density, bulk modulus, trimming modulus, cohesion, internal friction angle, and saturated uniaxial tensile and compressive strength parameters of the rock in the sensitive layer, and establish the constitutive relationship of the filling sensitive...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com