Engine rocker arm shaft rod material high-speed cutting equipment

A rocker shaft and engine technology, applied in shearing machine equipment, metal processing equipment, accessories of shearing machine, etc. The effect of high work efficiency and high equipment reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

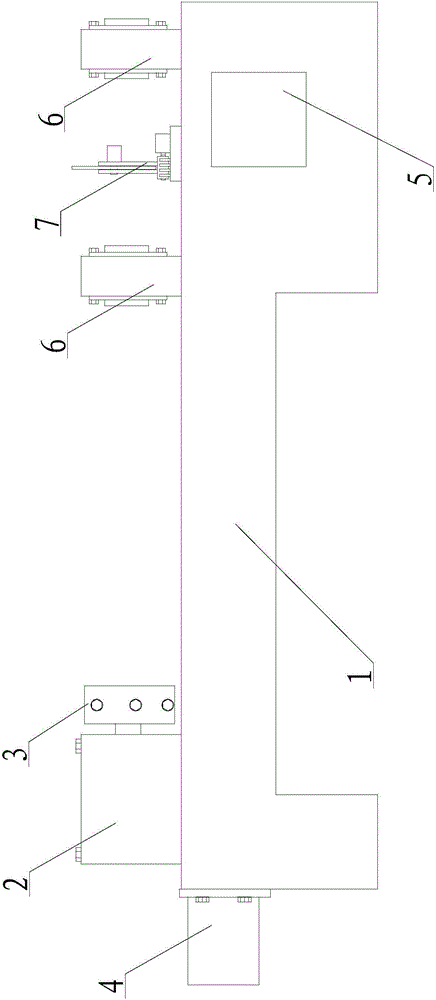

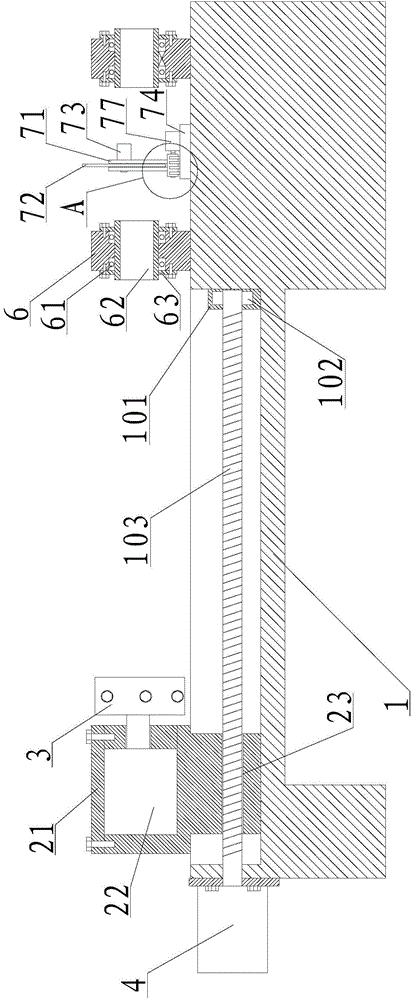

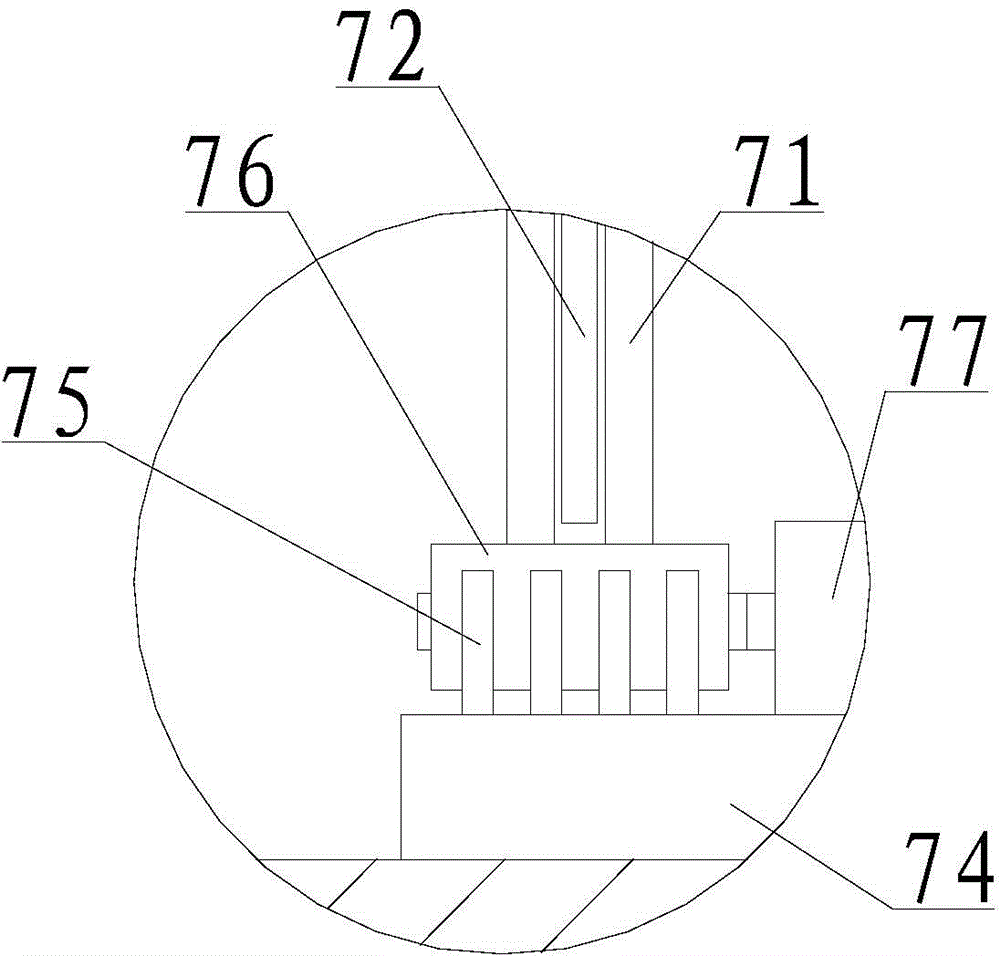

[0020] refer to figure 1 , figure 2 , image 3 and Figure 4 , the present invention is a high-speed interception equipment for engine rocker shaft and rod material, including a worktable 1, a feeding table 2, a screw 103, a clamping claw plate 3, a feeding motor 4, a control box 5, a support seat 6 and a cutting device 7 , a feeding table 2 is installed on the workbench 1, a material transfer motor 22 is installed inside the material feeding table 2, a clamping jaw plate 3 is installed on the material transfer motor 22, and a cover is installed on the upper part of the feeding table 2 through bolts plate 21, the lower part of the feeding table 2 is provided with a displacement hole 23, the left side of the workbench 1 is fixed with a feed motor 4 by bolts, and the feed motor 4 is connected with the lead screw 103, and the workbench 1 is provided with several support seats 6, so Two bearings 61 are installed on the support base 6, the side of the bearing 61 is fixed with a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com