Rapid order re-checking system

An order and fast technology, applied in the field of mail sorting, can solve the problems of high labor intensity, low degree of automation, and serious manpower consumption, and achieve the effects of reduced labor intensity, high degree of automation, and low input cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

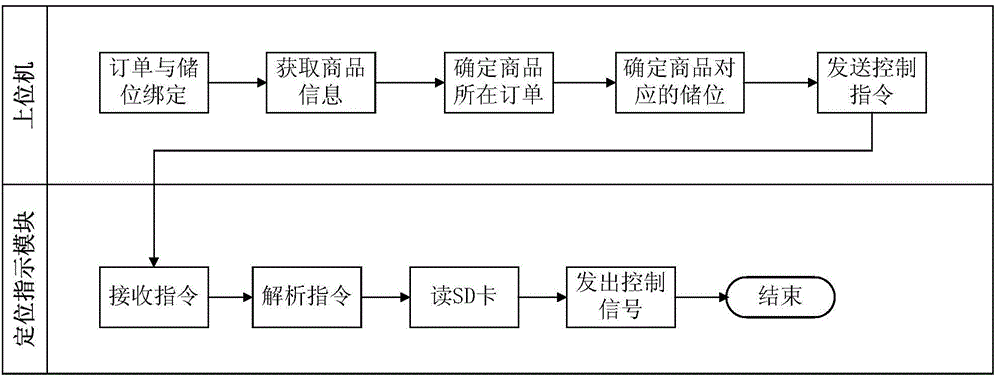

[0018] The technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

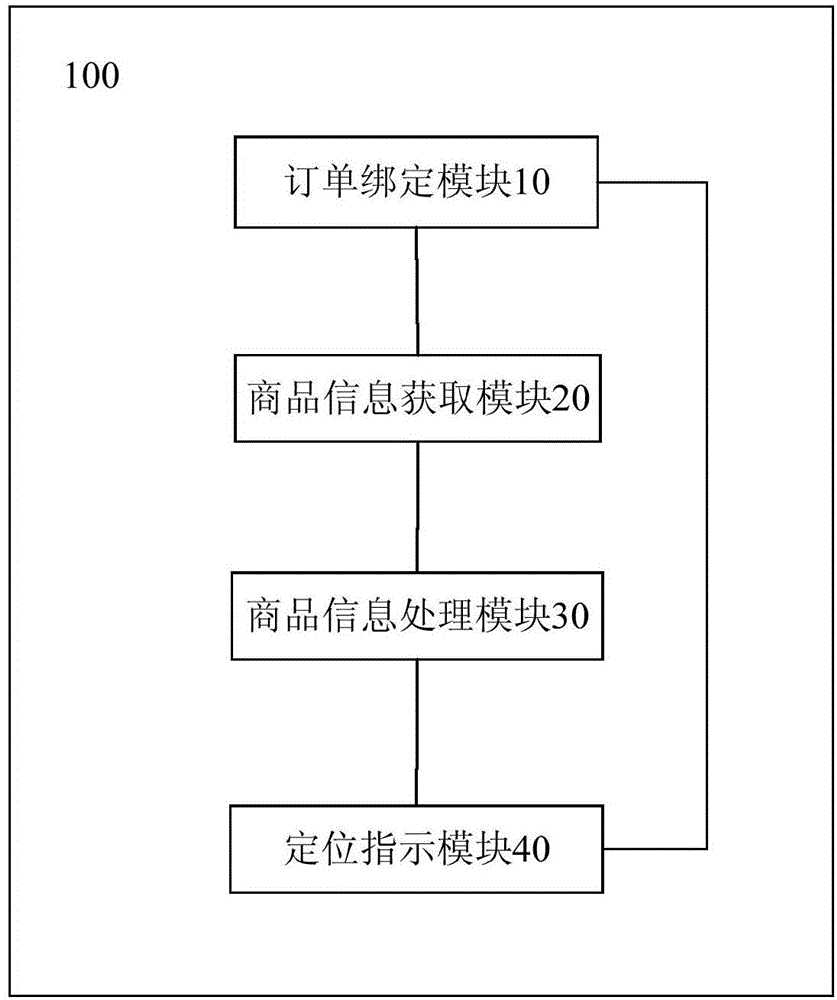

[0019] figure 1 A structural block diagram of a fast order review system 100 according to an embodiment of the present invention is shown, which includes:

[0020] The order binding module 10 is used to bind the order in the collection list with the storage space one-to-one;

[0021] Commodity information acquisition module 20, used to acquire commodity information and send the commodity information;

[0022] The commodity information processing module 30 is used to receive commodity information, determine the order to which the commodity belongs according to the commodity information, and determine the storage location to which the commodity belongs according to the binding relationship between the order and the storage location;

[0023] The positioning indication module 40 is used to determine the placement loc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com