Human Efficient Corn Planter

A kind of planting machine, high-efficiency technology, applied in the direction of planting methods, sowing seeders, planter parts, etc., can solve the problems of planting standardization and standardization requirements, no production efficiency planting equipment, affecting the accuracy of planting experiments, etc., to achieve production efficiency High, avoid swing, avoid the effect of damage to the connection parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

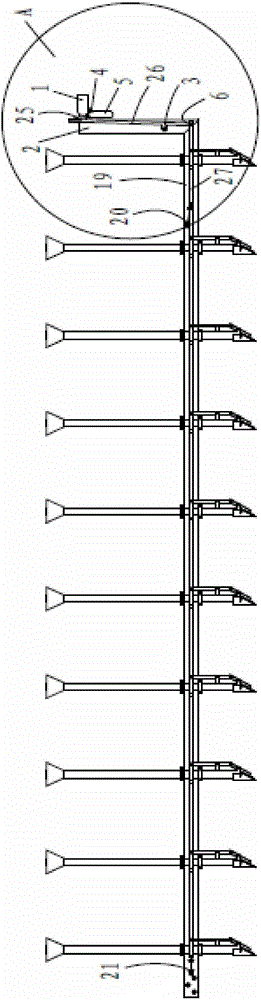

[0032] In order to better understand the present invention, the implementation manner of the present invention will be explained in detail below in conjunction with the accompanying drawings.

[0033] Such as Figure 1 to Figure 10 Shown, a kind of manpower high-efficiency corn planting machine comprises frame, ditching sowing structure, ditching sowing structure comprises seeder, ditch opener, and frame comprises the right side structure that connects, left side structure, and described frame The right side structure and the left side structure of the structure include connected horizontal support rods 19 and vertical support rods 2. The vertical support rods are arranged at the ends of the horizontal support rods, and the horizontal support rods are connected with the planters. The hand-held handle 1 placed is provided with a matching seed drop control plate 13 that is inclined downwards on the inner side of the opener 14. The seed drop control plate is connected to the cont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com