Novel automatic gas regulating mechanism for constant-temperature fuel gas water heater

A gas water heater and constant temperature technology, which is applied in the direction of engine components, mechanical equipment, valve operation/release devices, etc., can solve the problems that the minimum temperature rise of the water heater is difficult to control, the minimum temperature rise and the automatic adjustment temperature range are out of gear, etc., to achieve one-way Guaranteed safety, guaranteed sealing performance, and high adjustment accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

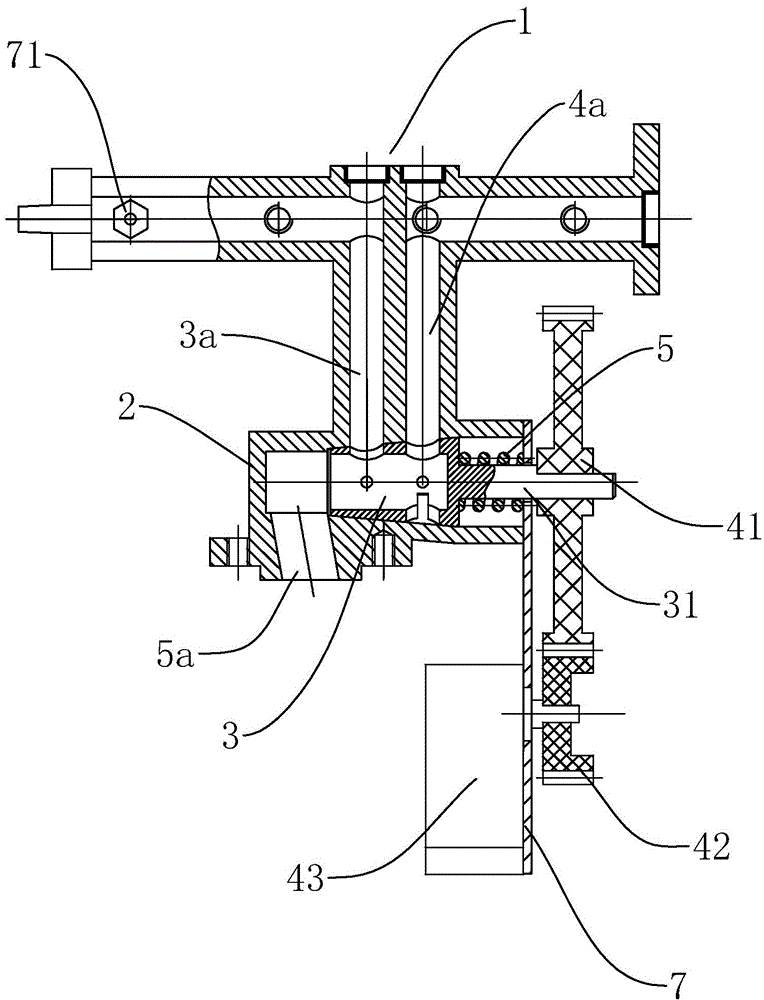

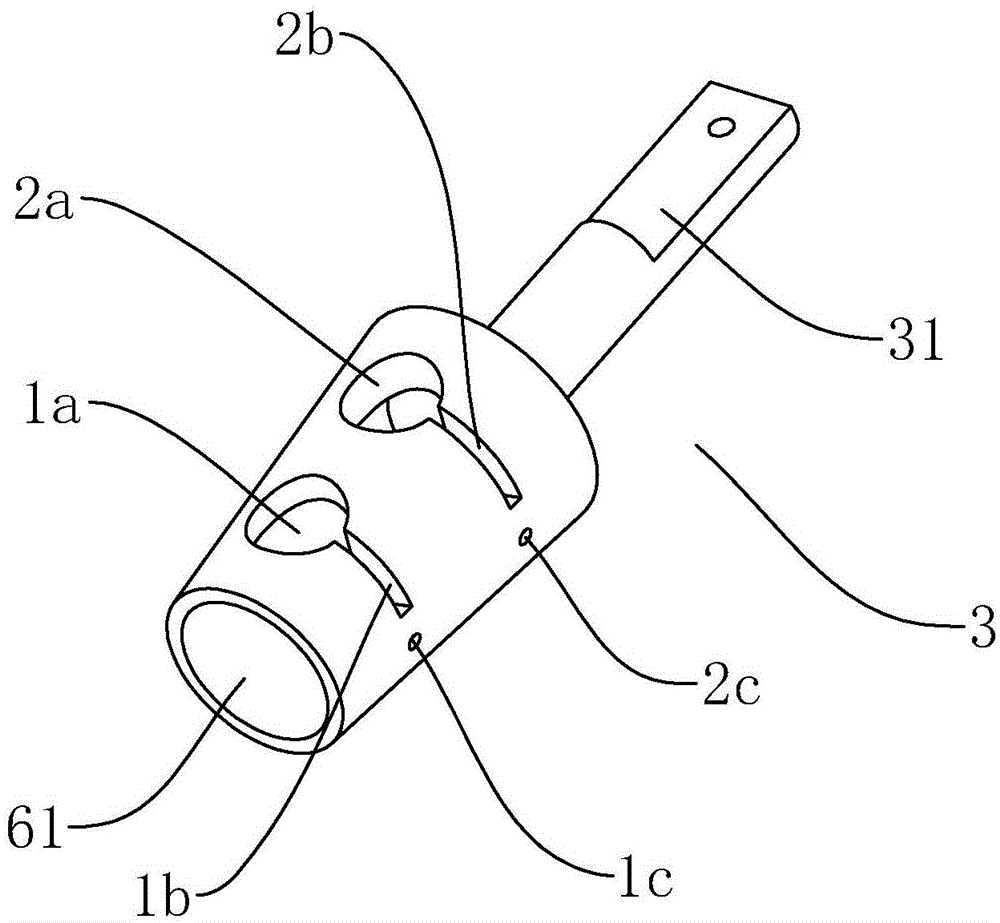

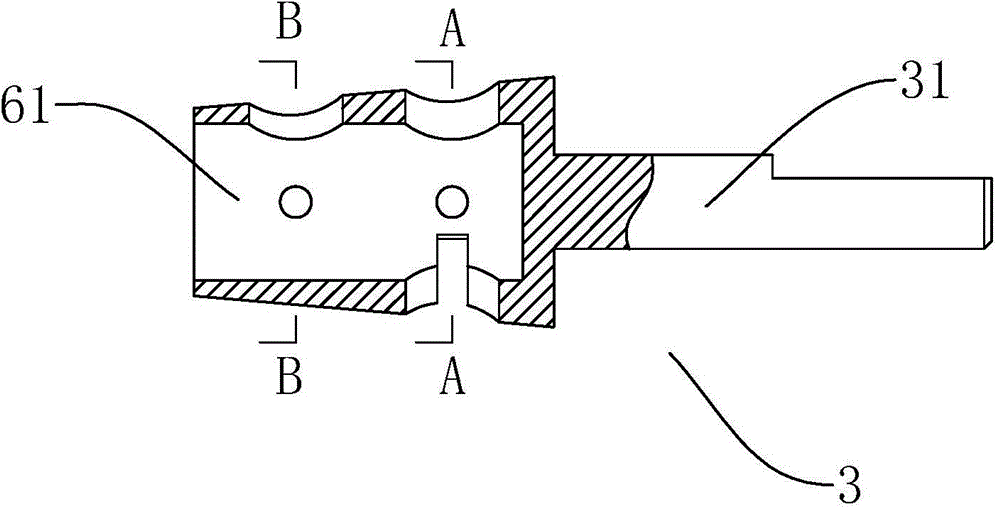

[0026] refer to Figure 1 to Figure 7 , Figure 1 to Figure 7 It is a structural schematic diagram of a specific embodiment of the present invention. As shown in the figure, a new type of automatic gas adjustment mechanism for a constant temperature gas water heater includes a gas distribution rod 1, a valve body 2, a valve core 3 and a valve core rotation drive mechanism. The valve body 2 is provided with a valve cavity hole connected to the gas passage of the gas distribution rod 1. The valve body 2 is also provided with a gas inlet 5a connected to the valve cavity hole. The valve core 3 is arranged in the valve cavity hole. The valve core 3 is provided with a number of vent holes capable of communicating with the gas inlet 5a and the gas distribution rod 1. The valve core 3 is a conical circular frustum structure, and the valve cavity hole is a conical hole corresponding to the valve core 3. The valve body 2 is also equipped with an elastic device capable of pressing the v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com