Sleeve type general expansion mold for precise expanding

A sleeve-type, precise technology, applied in the field of sleeve-type precision expanding general-purpose expansion molds, can solve problems such as high cost and complex structure, and achieve the effect of guaranteed strength, guaranteed accuracy, and convenient removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

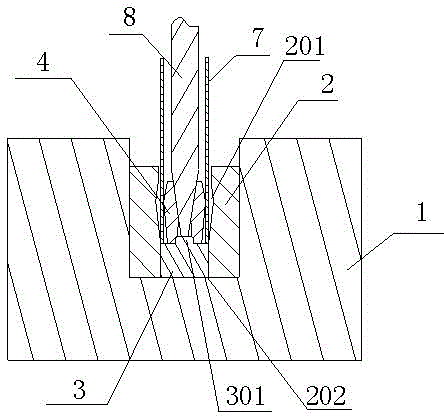

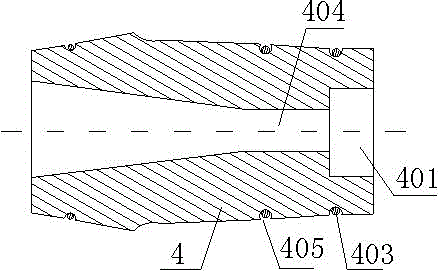

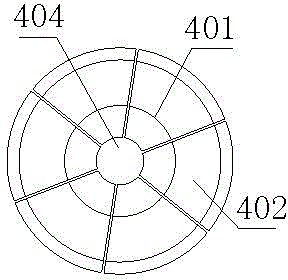

[0025] like Figure 1-3 As shown, the sleeve-type precision expanding general-purpose expansion mold includes a mold base 1, a concave mold 2, a positioning column 3 and an elastic combination module 4. The concave mold 2 is in the shape of a sleeve, and the concave mold 2 is vertically arranged on the On the mold base 1, one end of the barrel mouth 201 is directly facing the mold base 1 below, the positioning column 3 and the elastic combination module 4 are located in the through groove 202 of the die 2, the lower end of the positioning column 3 is installed on the mold base 1, and the upper end is provided with a The round table 301, the elastic combination module 4 is a rotary body, the center lines of the die 2, the positioning column 3 and the elastic combination module 4 overlap, and the center of the lower end of the elastic combination module 4 is provided with a groove 401 that matches the round platform 301, and the elastic combination The module 4 is evenly divided...

Embodiment 2

[0029] like Figure 4, the structure of this embodiment is basically the same as that of Embodiment 1, the difference is that a discharge device 5 is provided below the mold base 1, and the discharge device 5 includes a push rod 501, a push rod 502, and a push rod 503 , a push plate 507, and an upper backing plate 504, a pad cover A505, and a lower backing plate 506 arranged from top to bottom between the die 2 and the mold base 1, and the end of the ejector rod 501 is provided with A circular plate 508, the circular plate 508 is located in the sleeve hole of the cushion cover A505, the ejector rod 501 is located on the lower end surface of the circular plate 508, and passes through the lower backing plate 508, the mold base 1 is connected to the outside, and one end of the push rod 502 is fixed on the circular plate 508 The upper end surface, the other end passes through the upper backing plate 504 and the positioning column 3, and when the circular plate 508 is located at th...

Embodiment 3

[0033] like Figure 5 , the structure of this embodiment is basically the same as that of Embodiment 2, the difference is that the die 2 is fixed on the mold base 1 through a fixing device 6, and the fixing device 6 includes a compression sleeve 601 and a die fixing sleeve 604 , the die fixing sleeve 604 wraps the die 2, the die fixing sleeve 604 is located in the installation groove 101 on the upper surface of the mold base 1, the compression sleeve 601 is located above the die fixing sleeve 604, and the die fixing sleeve 604 is sealed in the installation In the groove 101 , the compression sleeve 601 is fixed on the mold base 1 , and the compression sleeve 601 is provided with a through hole facing the through groove 202 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com