Cradle easy to assemble and disassemble

An ore washing tank, easy disassembly and assembly technology, applied in the field of ore washing tank, can solve the problems of unfavorable transportation and reuse, and achieve the effect of ingenious structural design, easy disassembly and transportation, and increased reuse rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, so as to define the protection scope of the present invention more clearly.

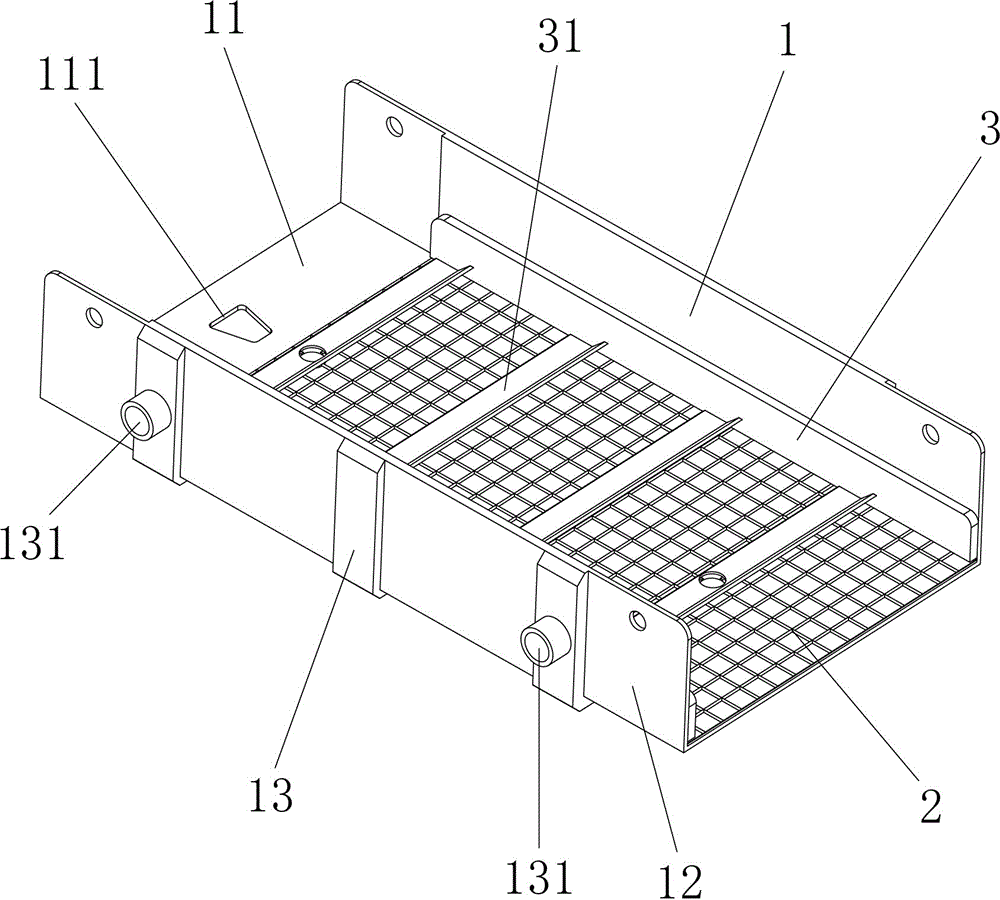

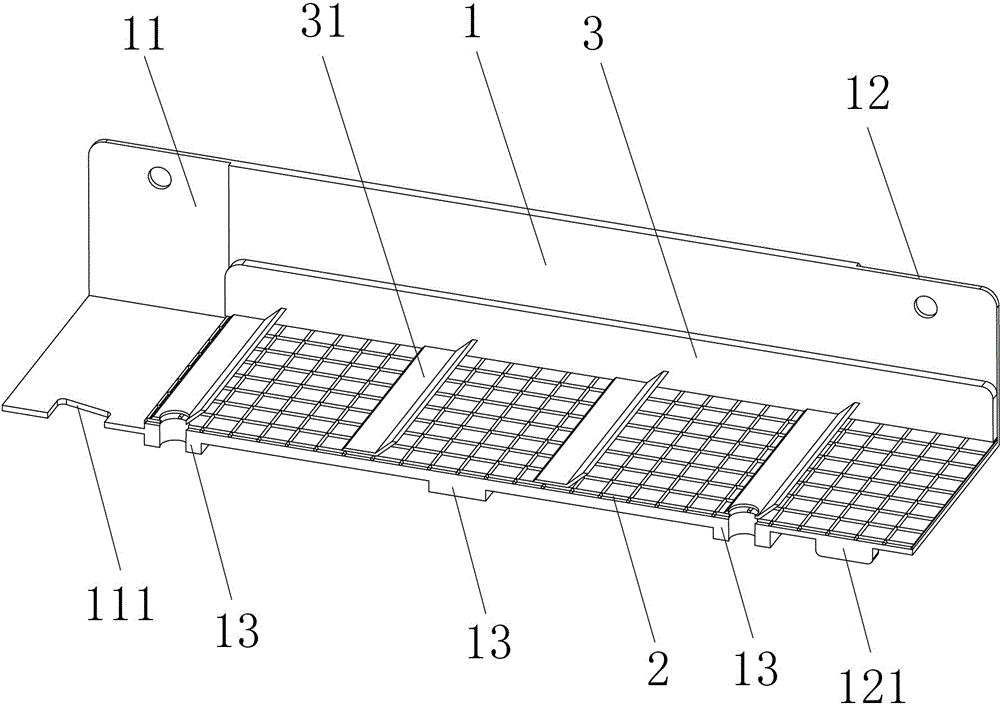

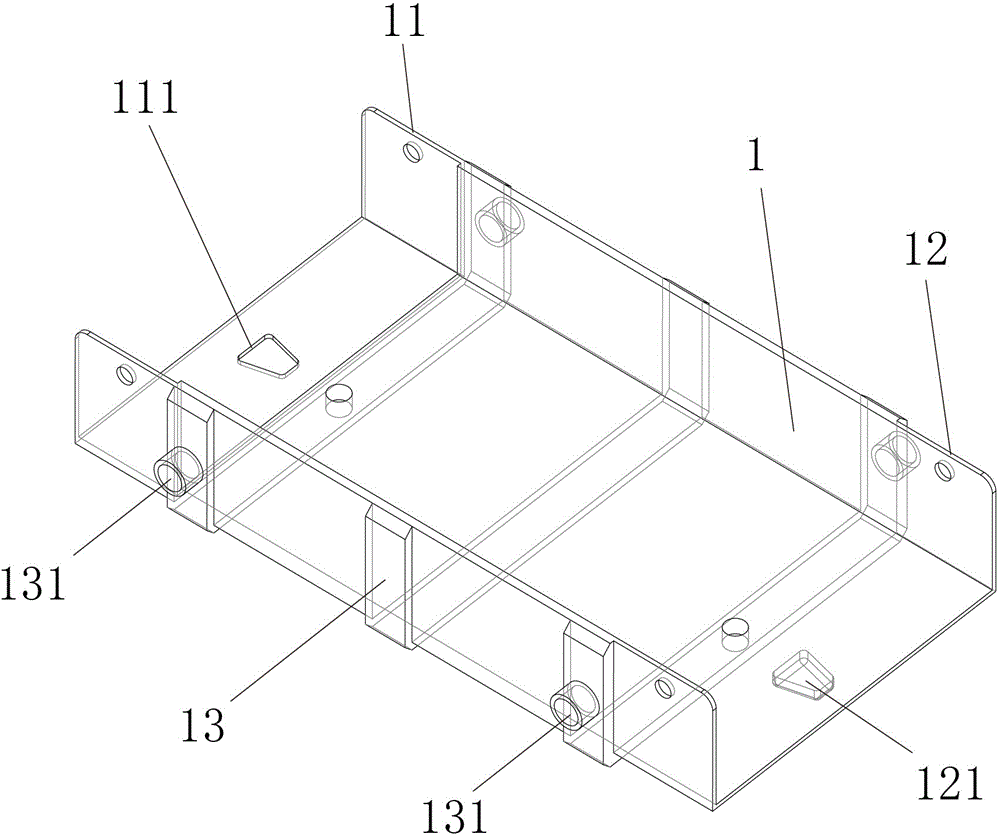

[0016] Such as Figure 1 to Figure 3 As shown, a kind of ore washing tank that is easy to disassemble mainly includes a tank assembly section 1, a steel mesh 2 and a rolling frame 3, and is characterized in that, the two ends of the tank assembly section 1 are respectively provided with docking tanks 11 and The docking plate 12, the bottom surface of the docking groove 11 is provided with a fastening hole 111, the bottom surface of the docking plate 12 is provided with a fastening platform 121, and the outer surface of the groove assembly section 1 is evenly distributed with three Reinforcing ribs 13, vibrating frame interfaces 131 are symmetrica...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap