Improved powder mixing equipment

A mixing equipment and improved technology, applied in the field of improved powder mixing equipment, can solve the problems of labor-consuming, raw material sinking, mixing dead ends, etc., to avoid powder adhesion, simple device structure, and prevent powder accumulation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

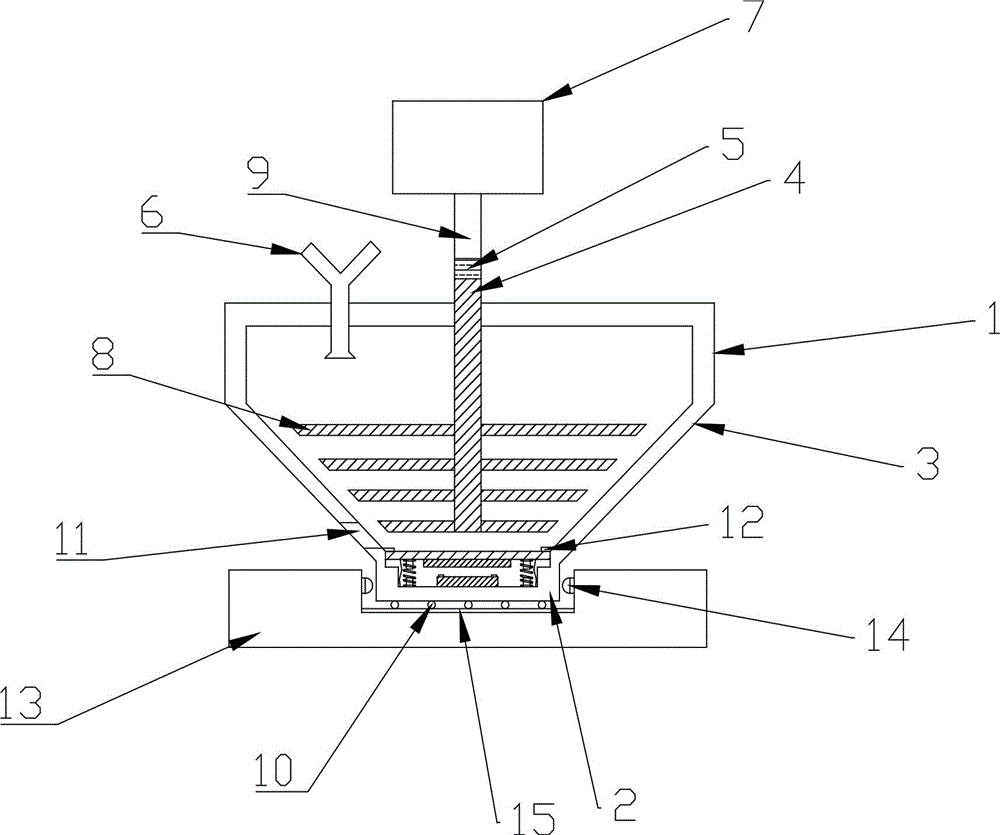

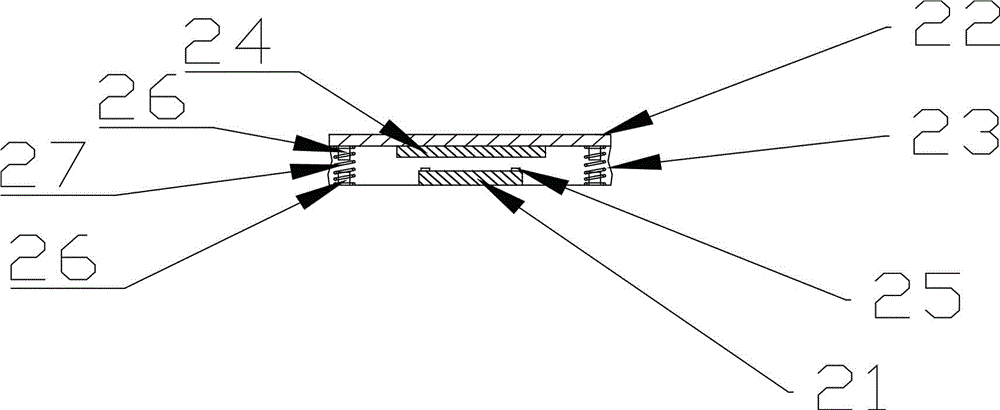

[0017] See Figure 1 to Figure 2 , an improved powder mixing equipment, including a cylinder base 2, a cylinder, a stirring device, a motor 7, and a base 13. Two positioning protrusions are arranged on the base 13, and the base 13 is provided with There are sliding tracks 15, several pulleys 10 are arranged under the cylinder base 2, buffer blocks 14 are arranged on the inner wall of the positioning protrusion on the base 13, and the pulleys 10 under the cylinder base 2 slide on the base The sliding in the track 15 enables the cylinder body to vibrate from side to side, so that the powder adhered to the side wall is shaken off, so that the powder mixing proceeds smoothly, the structure is simple, and the energy consumption is small. The positioning protrusion on the inner wall of the base 13 The buffer block 14 is provided so that the cylind...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com