Liquid crystal panel and display device

A liquid crystal panel and substrate technology, which is applied in the direction of instruments, nonlinear optics, optics, etc., can solve the problems affecting the uniformity of transmittance, etc., and achieve the effect of keeping the relative position unchanged

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

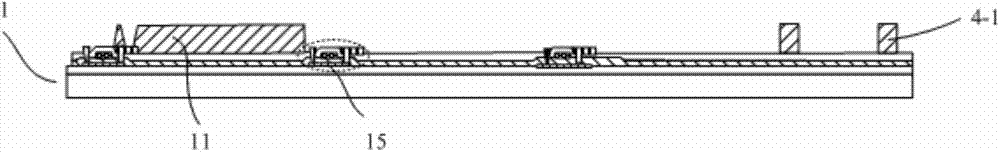

[0034] like figure 1 As shown, the present embodiment provides a liquid crystal panel, which includes a first substrate 1 and a second substrate 2 oppositely arranged, and a spacer 3 arranged between the first substrate 1 and the second substrate 2 . The spacers 3 are used to maintain the cell thickness of the liquid crystal panel to accommodate the liquid crystal layer 5 . Wherein, the first substrate 1 is a COA substrate (Color filter on Array; a color filter is formed on an array substrate), the second substrate 2 is a box-matching substrate, and spacers 3 are disposed on the box-matching substrate. In particular, on the COA substrate of the liquid crystal panel of this embodiment, a card slot 4 is provided, and the card slot 4 is used for the spacer 3 corresponding to it, so as to ensure that the COA substrate and the box-to-box substrate are arranged oppositely. The relative position remains unchanged.

[0035] Those skilled in the art can understand that the ratio of t...

Embodiment 2

[0047] like figure 2 As shown, this embodiment provides a liquid crystal panel, the structure of which is similar to that of the liquid crystal panel in Embodiment 1, and also includes a COA substrate and a cell-aligning substrate oppositely arranged. The difference is that the spacer 3 is arranged on the COA substrate, and the card slot 4 is arranged on the box-matching substrate.

[0048] In this embodiment, the liquid crystal panel can also clamp and fix the spacer 3 through the slot 4, so that the degree of deformation of the two is roughly the same, so that the relative position of the two does not change, thereby avoiding alignment between the two boxes. deviation.

Embodiment 3

[0050] This embodiment provides a liquid crystal panel, which includes a first substrate and a second substrate oppositely arranged, and a spacer arranged between the first substrate and the second substrate. Wherein the first substrate is an array substrate, and the second substrate is a color filter substrate. In particular, the color filter substrate of the liquid crystal panel of this embodiment is provided with a slot corresponding to the position of the spacer. The clamping slot is used to clamp the spacer corresponding to it, so as to ensure that the relative positions of the oppositely arranged COA substrate and the box-aligning substrate remain unchanged.

[0051] The action principle of the slot in this embodiment is the same as that of Embodiments 1 and 2, so the description will not be repeated here, so the liquid crystal panel of this embodiment can also hold and fix the spacer through the slot, so that both The degree of deformation is roughly the same, so as to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com