Tool and method for detecting concentricity of vacuum tubes of inner and outer foaming barrels of solar water tank

A solar water tank and detection tooling technology, which is applied to measuring devices, fluid utilization devices, instruments, etc., can solve the problem of being unable to visually and effectively detect whether the vacuum tube holes of the inner tank and the outer tank are concentric or not, so as to improve the overall quality of the product and increase the market share. Recognition, the effect of eliminating defective products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be specifically described below in conjunction with the accompanying drawings and embodiments.

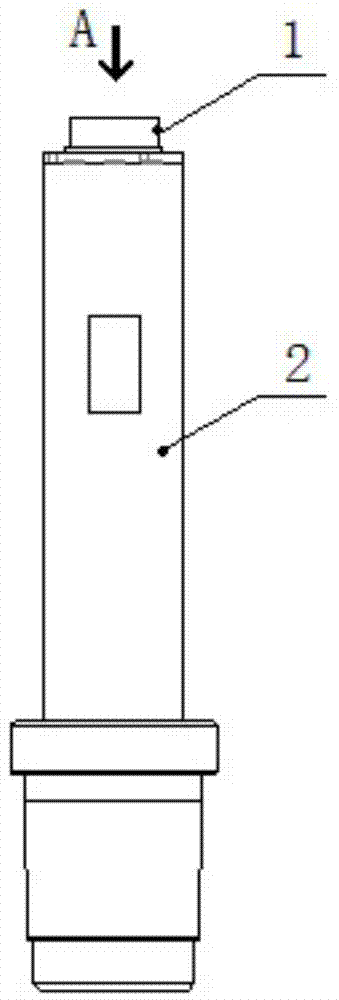

[0015] figure 1 Described is a schematic front view of the structure of the present invention.

[0016] The present invention includes a tooling main body 2, the tooling main body 2 is stepped cylindrical, and the shape and size of the head of the tooling main body 2 match with the vacuum tube of the solar water tank foaming inner and outer barrels.

[0017] The rear part of the tooling body 2 is equipped with a horizontal bubble 1, and the flatness of the tail plane of the tooling body 2 and the contact part of the horizontal bubble 1 and the tooling body 2 is relatively high, and the two planes coincide with the central axis of the tooling body 2.

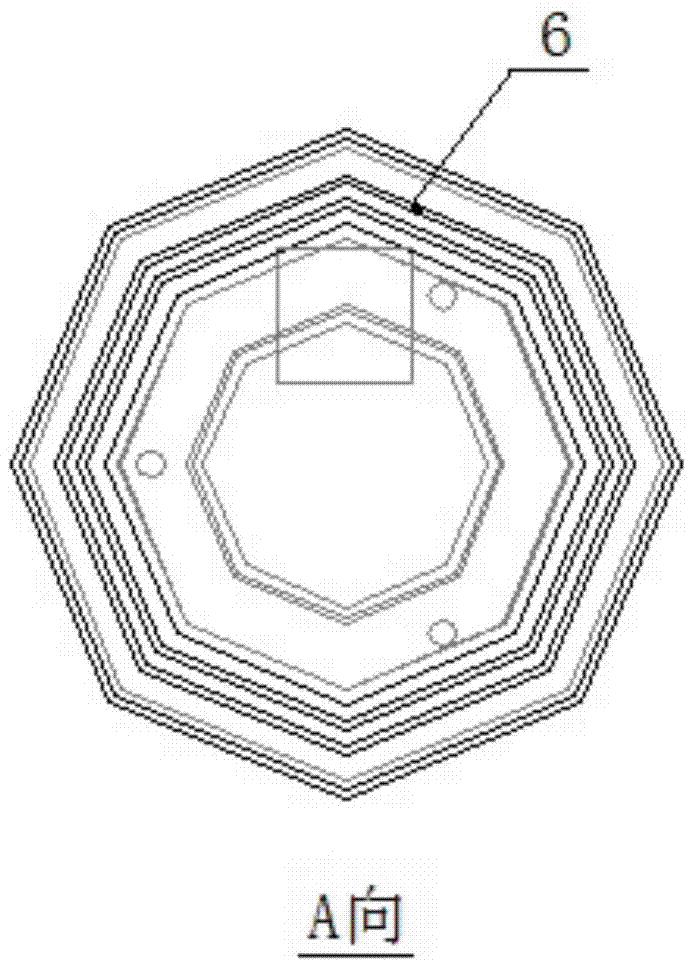

[0018] figure 2 Shown is the A-direction enlarged schematic diagram of the present invention.

[0019] The horizontal bubble 1 has a scale 6 of degrees of inclination.

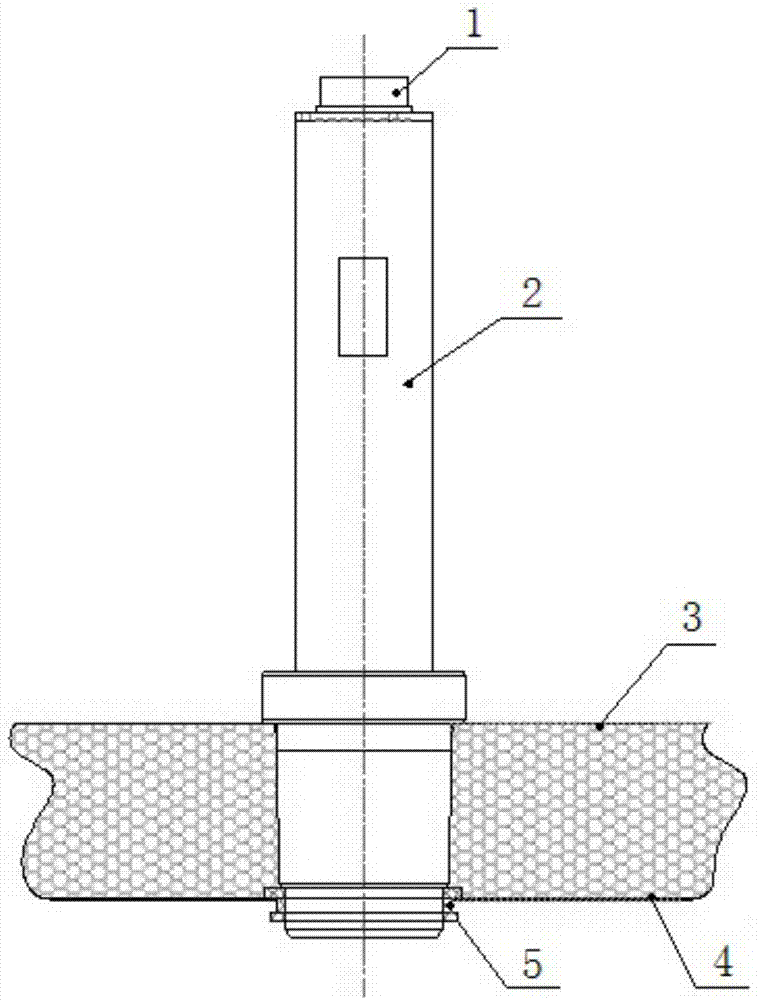

[0020] image 3 Shown is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com