Inner circulation ball screw component for airplane electric brake

A technology of ball screw and internal circulation, applied in mechanical equipment, belts/chains/gears, transmission devices, etc., can solve problems such as limited structural space and inability to meet the requirements of electric braking torque

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

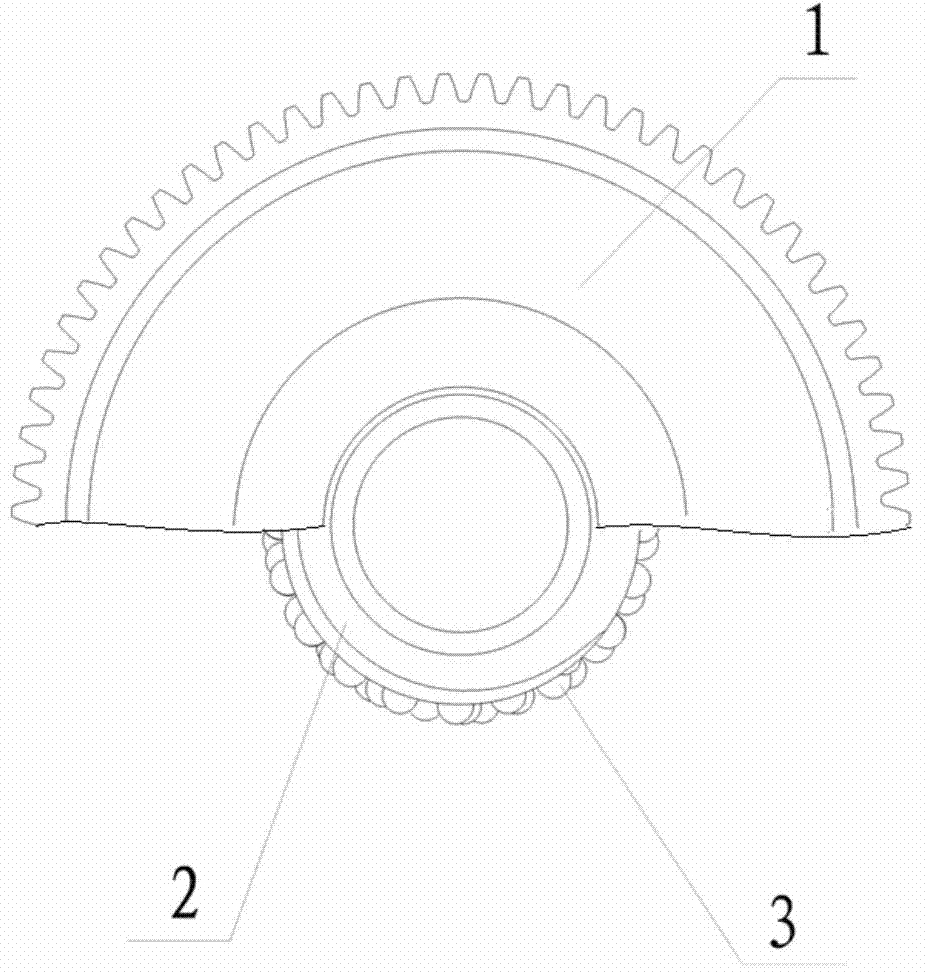

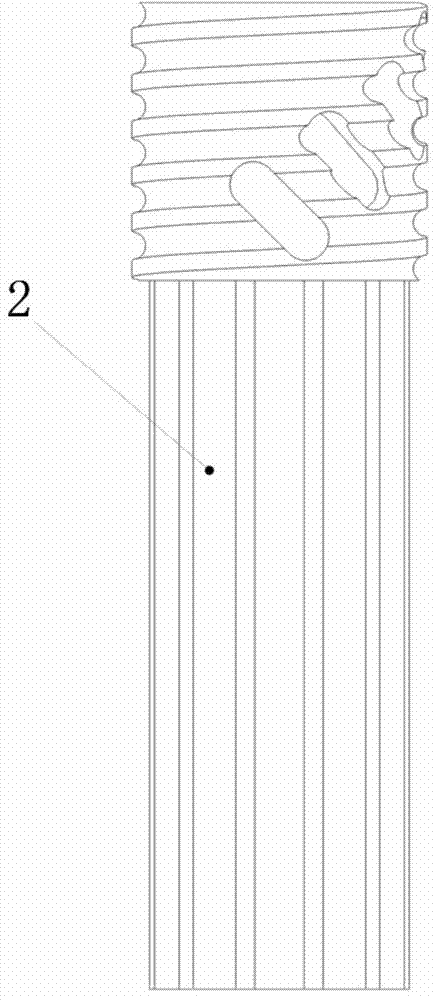

[0019] This embodiment is an internal circulation ball screw assembly for aircraft electric brakes, including a nut 1 , a screw 2 , a ball 3 and a reverser 4 . The nut 1 is a hollow rotating body, and the inner surface is processed with a helical semicircular groove. The lead screw 2 is located in the nut, and one end of the lead screw 2 is processed with a helical semicircular groove. After the nut is matched with the lead screw, the semicircular grooves respectively located on the nut and the lead screw are combined to form a circular groove, which is the ball raceway 5 .

[0020] Several balls 3 are placed in each of the ball raceways 5 . Between two adjacent ball raceways, a reverser mounting groove is processed. The included angle between the length direction centerline of each retroverter installation groove and the centerline of the lead screw is 45°; the misalignment between the adjacent retroverter installation grooves makes the adjacent There is no interference be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com