A composite shaft

A shaft and axial technology, applied in the field of torque transmission structure, can solve problems such as product control failure, damage, cable damage, etc., to avoid product cable damage and improve experience.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

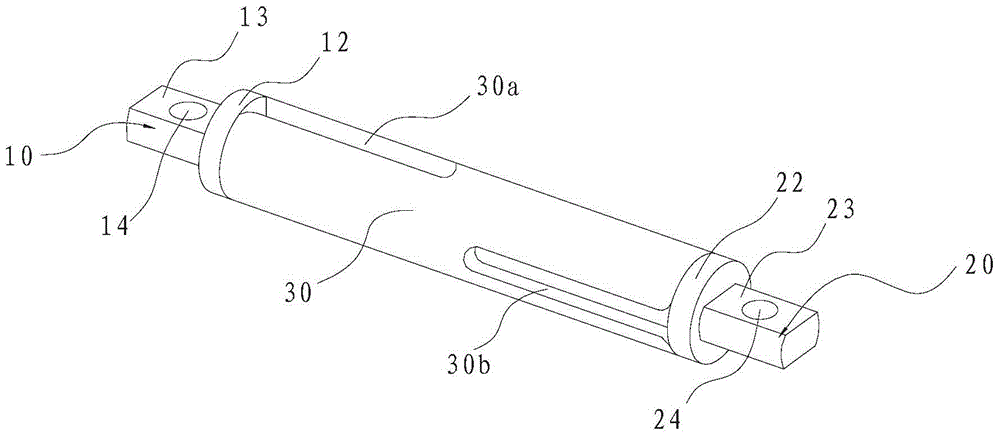

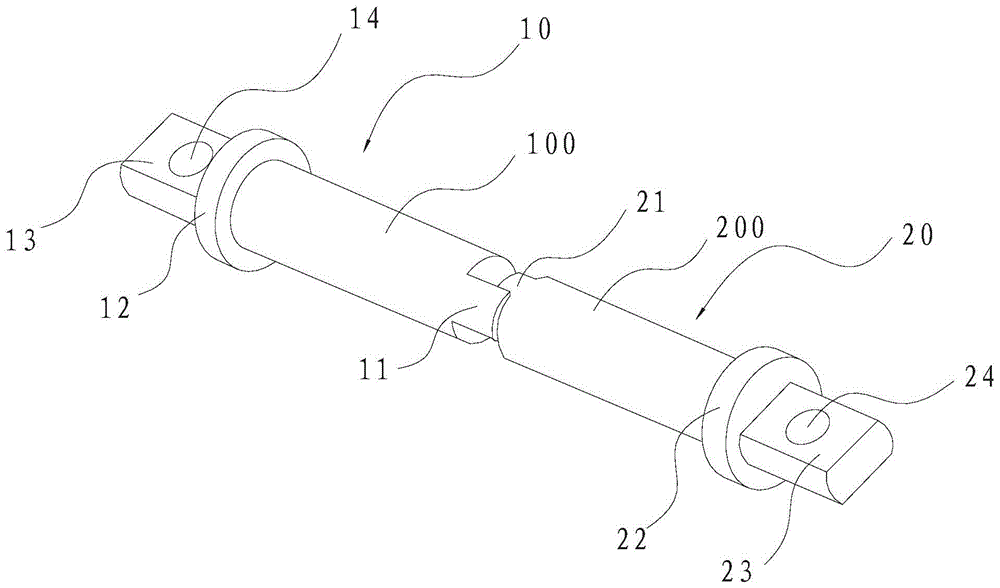

[0023] refer to figure 1 and figure 2 , the composite rotating shaft of the embodiment of the present invention includes a first rotating shaft 10, a second rotating shaft 20 and a sleeve 30, one end face of the first rotating shaft 10 and one end face of the second rotating shaft 20 are arranged oppositely, and the first rotating shaft 10 and the second rotating shaft The two opposite end faces of 20 are protrudingly provided with a first shaft head 11 and a second shaft head 21, and the first shaft head 11 and the second shaft head 21 have intervals in the circumferential direction for connecting the first rotating shaft 10 and the second shaft head. When the two rotating shafts 20 are relatively rotating around the circumference, they cooperate to limit the relative rotation angle between the first rotating shaft 10 and the second rotating shaft 20 .

[0024] By setting the sleeve 30, the first rotating shaft 10 and the second rotating shaft 20 are limited, so as to ensur...

Embodiment 2

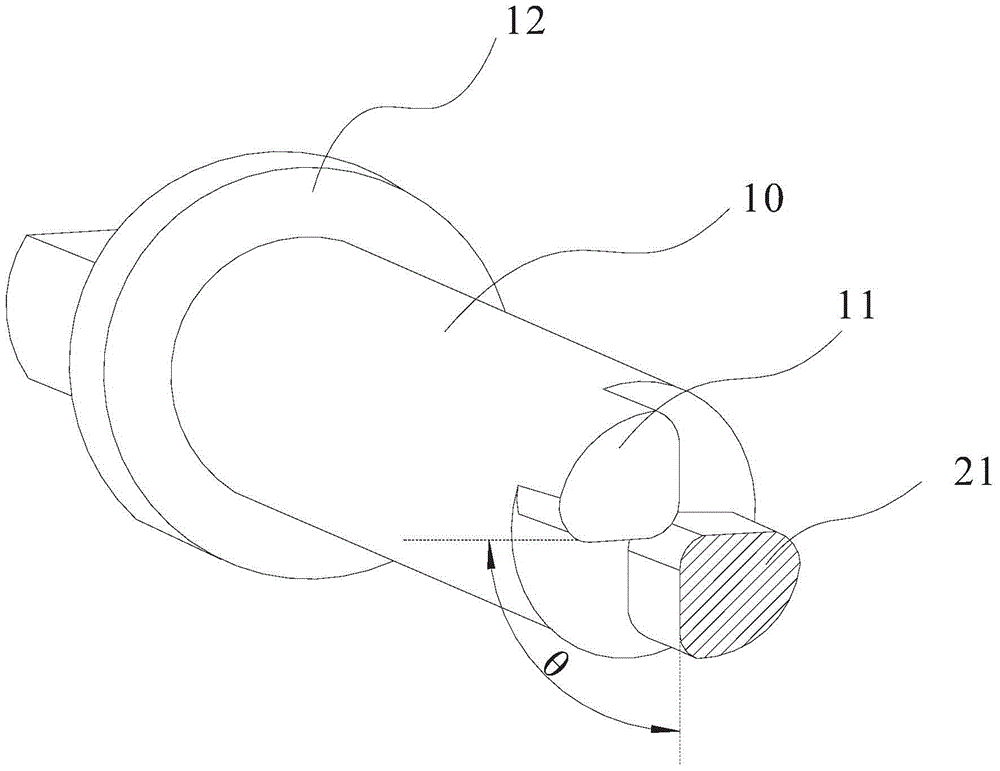

[0036] Such as Figure 4 As shown, it is a schematic diagram of the cross-sectional structure of the composite rotating shaft of this embodiment. The difference from Embodiment 1 is that there are multiple first shaft heads 11 and second shaft heads 21, and the centers of the first shaft 10 and the second shaft The center of the rotating shaft 20 is the center of the circle and is evenly arranged on the circumference, and the first shaft head 11 and the second shaft head 21 are arranged at intervals. The angle θ1 between the first shaft head 11 and the second shaft head 21 can be set according to actual rotation needs. By setting more shaft heads on the shaft, the contact area when the two shafts rotate is further increased, effectively dispersing the stress generated during the rotation process, and protecting the shaft head structure.

Embodiment 3

[0038] This embodiment also provides a wearable device, the wearable device at least includes two first connectors (not shown) and second connectors (not shown) connected to each other, the first connector and A connecting line is provided between the second connecting parts, and the first connecting part is connected to the second connecting part by the composite rotating shaft described in any one of the previous embodiments.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com